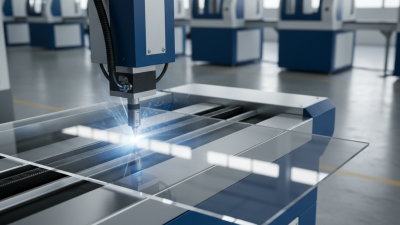

Customized Ultrasonic Welding Equipment: ODM Manufacturers & Suppliers

When I search for Customized Ultrasonic Welding Equipment, I know how crucial it is to partner with a reliable manufacturer who understands my unique needs. That's why I've chosen to work with Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. Their team specializes in tailor-made solutions, ensuring that each piece of equipment is designed specifically for my factory requirements, With years of experience in the industry, they focus on blending technology with practicality, making sure that the welding equipment not only meets but exceeds my expectations. Whether I need a compact machine for small-scale production or a robust setup for large operations, their flexibility and commitment to quality have made all the difference, Their support throughout the purchasing process is exceptional, answering my questions and providing the insights I need to make informed decisions. If you're looking for a partner to enhance your production capabilities, I highly recommend considering their expertise in customized ultrasonic welding solutions

Reasons to Choose Customized Ultrasonic Welding Equipment Supplies the World’s Top Brands Manufacturer

Choosing the right ultrasonic welding equipment is crucial for manufacturers looking to enhance efficiency and precision in their production processes. For over 20 years, Chengguan has established itself as a leader in the ultrasonic Plastic Welding industry, supplying cutting-edge technology that meets the demands of various sectors. Our customized ultrasonic welding systems are designed to cater to unique manufacturing needs, ensuring optimal performance and adaptability in your operations. What sets Chengguan apart is our commitment to innovation and quality. We provide a comprehensive range of ultrasonic equipment, from welding systems to ultrasonic lacing, cutting, extraction, and homogenization tools. This versatility allows us to serve top brands across the globe, making us a trusted partner in the pursuit of technological excellence. By choosing Chengguan, you gain access to tailored solutions that not only improve product quality but also streamline your production process, ultimately driving profitability. In an ever-evolving market, staying ahead requires reliable and effective equipment. Our ultrasonic solutions are engineered with the latest advancements in technology, ensuring that our clients benefit from increased speed, reduced waste, and improved product integrity. Collaborating with Chengguan means aligning your business with a brand that prioritizes customer satisfaction and continuous improvement, making us the ideal choice for procurement in ultrasonic welding equipment on a global scale.

Reasons to Choose Customized Ultrasonic Welding Equipment Supplies the World’s Top Brands Manufacturer

| Feature | Benefit | Customization Options | Typical Applications |

|---|---|---|---|

| High Precision | Ensures consistent quality in bonding | Various sonotrode designs | Automotive components |

| Energy Efficiency | Reduces operational costs | Power settings adjustment | Consumer electronics |

| Durability | Longer lifespan of equipment | Materials customization | Medical devices |

| Versatility | Suitable for various materials | Length and frequency variations | Textile industry |

| Automation Ready | Integrates easily into production lines | Interface configurations | Packaging industry |

Cutting-Edge Customized Ultrasonic Welding Equipment Exceeds Industry Benchmarks From Concept to Delivery

J

Jason Reed

This product is robust and reliable! The after-sales support made my experience even better.

01 July 2025

E

Ella Davis

The quality is amazing! The after-sales team was responsive and genuinely cares for their customers.

01 June 2025

S

Sophie Gonzalez

I can’t express how pleased I am! The quality and after-sales support were both exemplary.

21 May 2025

L

Luke Phillips

The quality truly stands out! The support team was not only professional but also very friendly.

21 June 2025

C

Cody Wright

Very happy with the product! The service team was attentive and knowledgeable.

08 June 2025

C

Carter Ward

Outstanding experience! The quality stands out, and the staff was highly professional and helpful.

24 May 2025