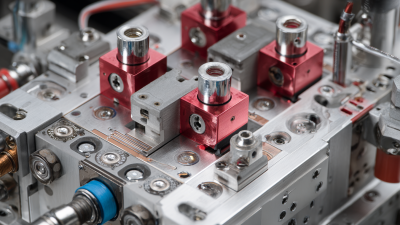

High-Quality Electronic Component Welding by Leading Exporter & Manufacturer

At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we understand the evolving needs of factories and suppliers in the electronic component welding industry. Our custom ultrasonic welding solutions meet diverse production requirements, ensuring high-quality joins that enhance the performance and reliability of your products. We pride ourselves on crafting equipment tailored to your unique specifications, helping you optimize your manufacturing processes and reduce costs, With extensive experience in the field, I personally ensure that our Welding Systems integrate seamlessly into your existing operations. Whether you are a small factory or a large supplier, we are committed to delivering equipment that not only meets industry standards but also exceeds your expectations. Our dedicated support team is here to assist you, making the transition to advanced welding technology as smooth as possible. Partner with us to elevate your production capabilities and stay ahead in the competitive market of electronic component welding

Tips & Tricks for Electronic Component Welding Factory-Direct Excellence Exceeds Industry Benchmarks

In the ever-evolving landscape of manufacturing, excellence in ultrasonic plastic welding has become a vital benchmark. For over 20 years, Chengguan has been at the forefront of this technology, delivering unparalleled systems and equipment that not only meet but exceed industry standards. As a recognized leader, we provide a range of products including ultrasonic welding systems, lace equipment, cutting tools, extractors, and homogenizers tailored to various industries. Our commitment to innovation ensures that your production processes are both efficient and reliable. To help global buyers navigate the complexities of sourcing, we offer essential tips and tricks for selecting the right ultrasonic welding solutions. First, prioritize quality assurance—look for manufacturers like Chengguan that have a proven track record and maintain stringent quality control measures. Second, consider the versatility of the equipment; our systems are designed for multiple applications, ensuring you receive maximum value from your investment. Lastly, don’t overlook post-purchase support. A manufacturer committed to customer service will provide training and technical support, essential for optimizing your operations and minimizing downtime. By choosing Chengguan as your partner in ultrasonic plastic welding, you tap into two decades of expertise and a commitment to excellence that resonates within the industry. Let us help you achieve superior results that stand above the competition, ensuring that your production processes are not just efficient, but exemplary.

Tips & Tricks for Electronic Component Welding Factory-Direct Excellence Exceeds Industry Benchmarks

| Process Step | Best Practices | Efficiency Rating (%) | Error Rate (%) | Notes |

|---|---|---|---|---|

| Solder Joint Preparation | Ensure clean surfaces, use flux appropriately | 95 | 2 | Critical for reliability |

| Temperature Control | Monitor soldering temperature closely | 90 | 3 | Prevents component damage |

| Soldering Techniques | Use proper techniques for through-hole and SMT | 92 | 2.5 | Skill level impacts quality |

| Inspection Procedures | Implement regular quality control checks | 93 | 1.5 | Identifies issues early |

| Training & Development | Continual training for staff | 94 | 1 | Keep skills updated |

Where the Value Lies Electronic Component Welding Trusted by Pros Your Trusted OEM Partner

A

Abigail Wright

A top-tier product with exceptional after-sales support! The staff were all true professionals.

26 May 2025

E

Ella Davis

The quality is amazing! The after-sales team was responsive and genuinely cares for their customers.

01 June 2025

M

Megan Rivera

Thrilled with my purchase! The after-sales professionals were experts and really helped me.

28 June 2025

N

Noah Gray

Impressive quality and the service team was incredibly helpful! Highly recommended.

21 May 2025

S

Samantha Sanchez

Unbelievable quality! The staff helped me navigate everything smoothly with their expertise.

02 June 2025

Z

Zoe Martinez

Truly a remarkable product! The knowledge and professionalism of the support staff are unmatched.

01 June 2025