Friction Heating Welding ODM Manufacturers & Exporters for Quality Solutions

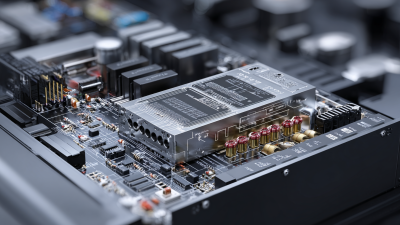

In the world of industrial manufacturing, Friction Heating Welding stands out as a reliable, efficient solution for high-quality bonding. As an OEM supplier and exporter, we prioritize innovation and durability in our products. My experience with Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has shown me the remarkable advantages of using Friction Heating Welding technology, It allows us to create strong joints without the need for additional materials, saving both time and cost. Whether you are working in the automotive, electronics, or general manufacturing sectors, our solutions meet diverse needs. I invite you to collaborate with us to enhance your production capabilities. We’re dedicated to providing superior quality equipment tailored to your specifications. Let’s work together to revolutionize your manufacturing process with our cutting-edge solutions. Reach out today and see how we can support your business goals effectively!

Best Ways To Friction Heating Welding Market Leader More Than a Supplier - A Partner

In today's competitive marketplace, businesses are increasingly recognizing the value of partnerships over mere supplier relationships. Chengguan, with two decades of expertise in ultrasonic plastic welding, exemplifies this shift. Our commitment extends far beyond simply providing top-notch ultrasonic plastic Welding Systems and equipment. We pride ourselves on being a proactive partner to our clients, ensuring their unique needs are met with precision and innovation. Our range of solutions—including ultrasonic lace equipment, cutting equipment, ultrasonic extractors, and homogenizers—positions us as a versatile ally in various industries. We understand that every project is distinct, prompting us to collaborate closely with our customers to develop tailored solutions that drive efficiency and success. By leveraging the latest technological advancements, we enable our partners to enhance their production processes and maintain a competitive edge. Choosing Chengguan means opting for a partnership that prioritizes your goals. As we continue to lead the friction heating welding market, we remain dedicated to fostering long-term relationships, investing in shared progress, and ensuring our partners not only succeed but thrive in their respective markets. Together, we can turn innovative ideas into transformative outcomes.

Best Ways To Friction Heating Welding Market Leader More Than a Supplier - A Partner

| Application | Industry | Benefits | Key Technologies |

|---|---|---|---|

| Automotive Component Joining | Automotive | High strength, Reduced weight | Friction Stir Welding, Rotary Friction Welding |

| Railway Track Welding | Rail | Increased durability, Faster installation | Friction Welding, Flash Welding |

| Heavy Equipment Assembly | Construction | High precision, Cost efficiency | Friction Welding, Induction Heating Welding |

| Aerospace Component Fabrication | Aerospace | Weight reduction, Enhanced performance | Friction Stir Welding, Friction Spot Welding |

| Pipeline Construction | Oil & Gas | Seamless joints, Reliability | Friction Welding, Linear Friction Welding |

Excellence in Friction Heating Welding Service Backed by Expertise Factory

M

Mia Walker

This product is exceptional in quality! Plus, the after-sales staff were well-trained and very helpful.

29 June 2025

L

Lily Parker

The quality is outstanding! The staff provided excellent after-sales service that exceeded my expectations.

17 June 2025

J

Joshua Hill

This purchase was a wise decision! The support team showcased professionalism throughout.

17 June 2025

E

Emily Reed

Wonderful item! The customer service was exceptional and made me feel valued.

30 May 2025

L

Landon Bell

A fantastic experience! The quality is evident, and the support team exemplifies professionalism.

02 July 2025

O

Olivia Adams

Absolutely wonderful! The quality of the product and the after-sales service worked perfectly together.

25 June 2025