Custom Friction Welding Solutions from Leading Exporters and Factories

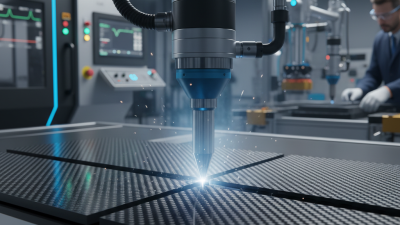

When it comes to advanced welding solutions, I firmly believe that Friction Welding stands out. It's a process I’ve seen transform manufacturing practices, ensuring strong and reliable joints in various materials. Our products are CE Certified, which gives you the assurance of safety and quality that you positively need for compliance with international standards, As a manufacturer, we pride ourselves on our state-of-the-art factories designed specifically for producing high-quality ultrasonic equipment. I understand that selecting the right partner is crucial for your business, and that’s where we come in. We aim to provide not just equipment but also the expertise that helps optimize your production line. If you're looking to improve efficiency and quality in your welding processes, let’s connect and explore how our solutions can meet your needs

Best Practices For Friction Welding Trusted by Pros Where Innovation Meets 2025

Friction welding technology has become a game changer in the manufacturing sector, especially as we approach 2025 and beyond. This innovative method, favored by professionals, marrying efficiency with superior results, has opened new avenues for industries requiring robust and reliable joining solutions. As manufacturers strive for sustainability and efficiency in production, friction welding offers significant advantages - from reduced energy consumption to minimal waste generation. Incorporating advanced automation and precision engineering, friction Welding Systems cater to diverse sectors, ranging from automotive to packaging. The lightweight, strong joints produced through this technique not only enhance product performance but also contribute to sustainability goals, making it an ideal choice for contemporary manufacturing needs. For procurement professionals and global buyers, understanding the nuances of friction welding can provide a competitive edge, ensuring that investments lead to long-term savings and quality improvements in their product lines. As we look to the future, it's essential for decision-makers to partner with trusted suppliers who are at the forefront of innovation. Collaborating with experts in the field ensures access to the most advanced technologies and best practices in friction welding, helping businesses to drive growth and maintain relevance in an ever-evolving market landscape. Embracing these practices will not only elevate production capabilities but also secure a firm place in the future of manufacturing.

Best Practices For Friction Welding Trusted by Pros Where Innovation Meets 2025

| Best Practice | Description | Expected Outcome | Industry Applications |

|---|---|---|---|

| Material Selection | Choose compatible materials to ensure optimal bonding. | Improved weld strength and durability. | Automotive, Aerospace |

| Control Parameters | Optimize speed, pressure, and time settings. | Consistent quality and minimized defects. | Manufacturing, Electronics |

| Surface Preparation | Ensure surfaces are clean and free from contaminants. | Enhanced bond quality and performance. | Construction, Energy |

| Post-Weld Treatment | Apply heat treatment to relieve stress. | Increased reliability and lifespan of the weld. | Infrastructure, Heavy Equipment |

| Periodic Maintenance | Regularly maintain equipment to prevent failures. | Increased operational efficiency and reduced downtime. | Manufacturing, Aerospace |

Reasons to Choose Friction Welding Factory Application

J

James Johnson

Impressive craftsmanship and excellent post-purchase support! The response from the service team was prompt and helpful.

14 May 2025

V

Victoria Bennett

Wonderful quality! The after-sales personnel were educated and genuinely caring.

09 May 2025

N

Nicholas Howard

Top quality! The support team was swift to respond and truly patient with my queries.

05 June 2025

H

Henry Bennett

My best purchase yet! The product’s quality and staff professionalism are commendable.

09 May 2025

L

Landon Bell

A fantastic experience! The quality is evident, and the support team exemplifies professionalism.

02 July 2025

C

Cody Wright

Very happy with the product! The service team was attentive and knowledgeable.

08 June 2025