CGSONIC ultrasound provides new enabling support for Horn's personalized solutions.

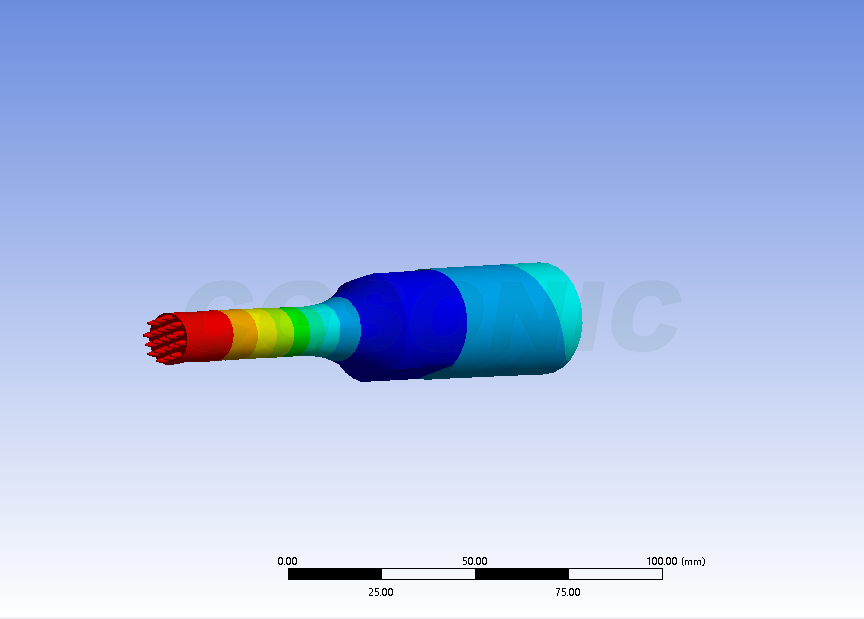

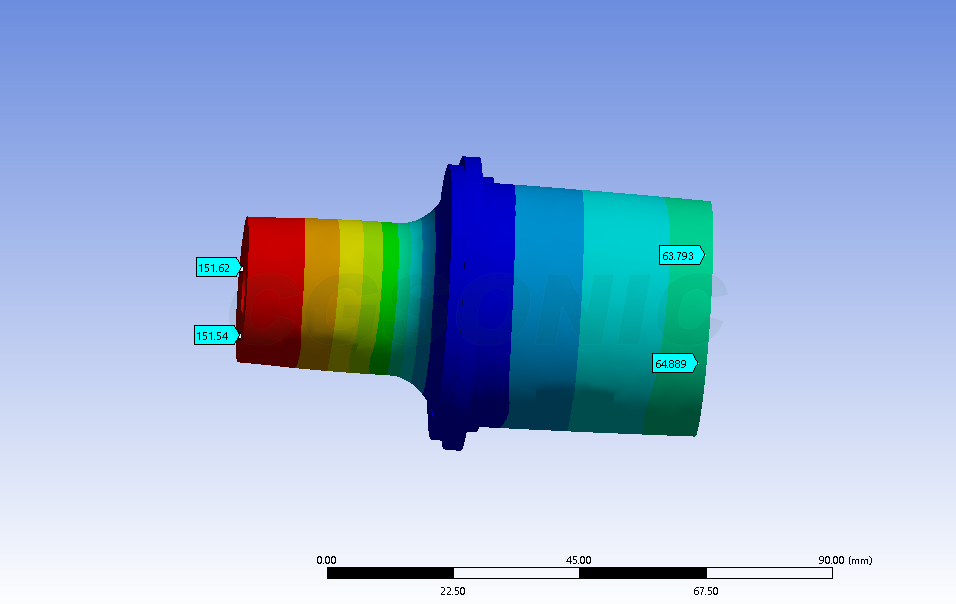

In the global industrial manufacturing sector, the demand for personalized customization is growing. As a leading company in ultrasonic technology, CGSONIC recently announced the launch of its new Horn (ultrasonic loudspeaker) customization service. Based on product images, materials, dimensions, or 3D drawings provided by customers, CGSONIC can precisely create ultrasonic loudspeakers of any shape and size to meet diverse application needs.

- Leading technology, customized services covering all needs

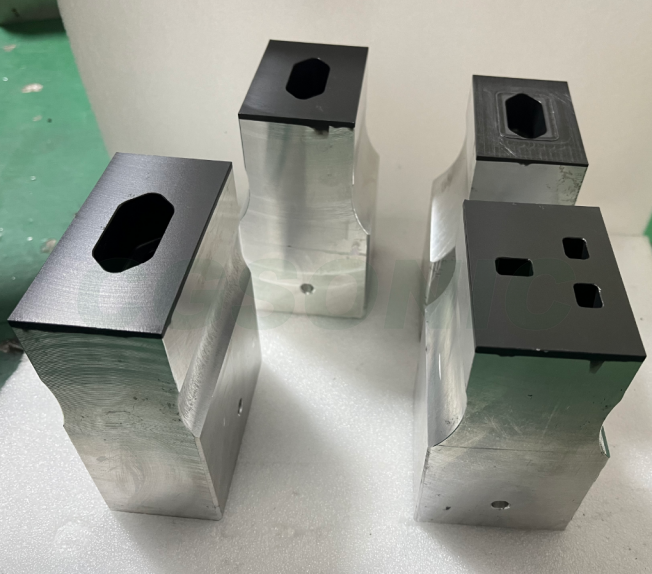

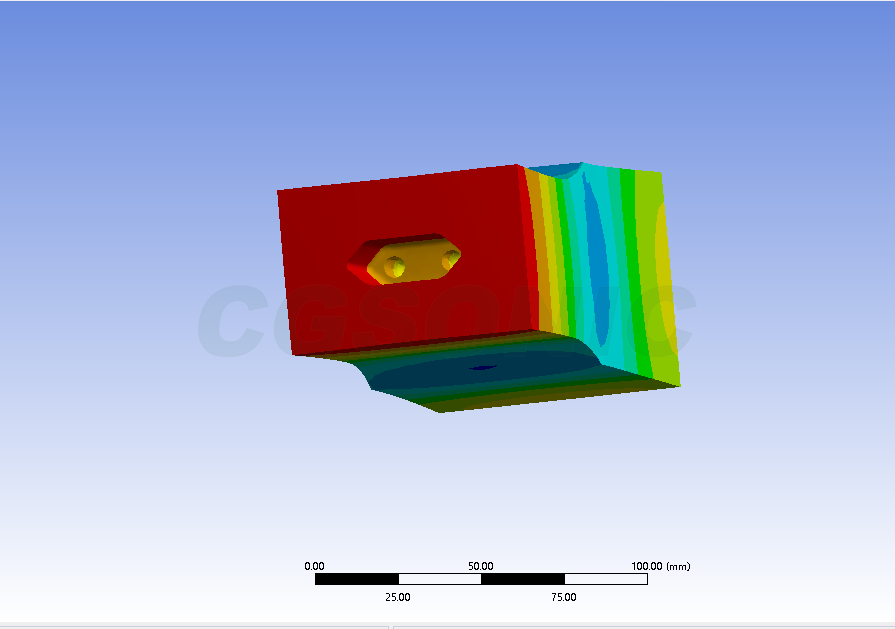

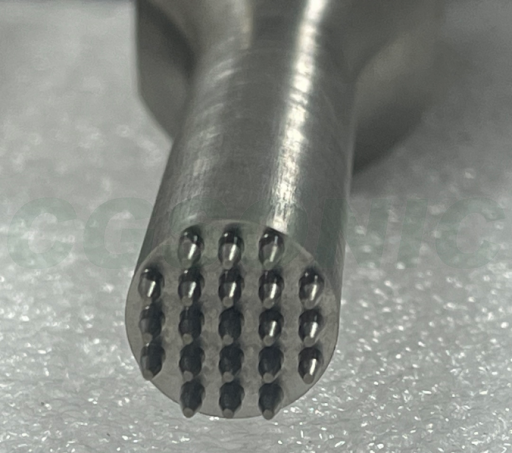

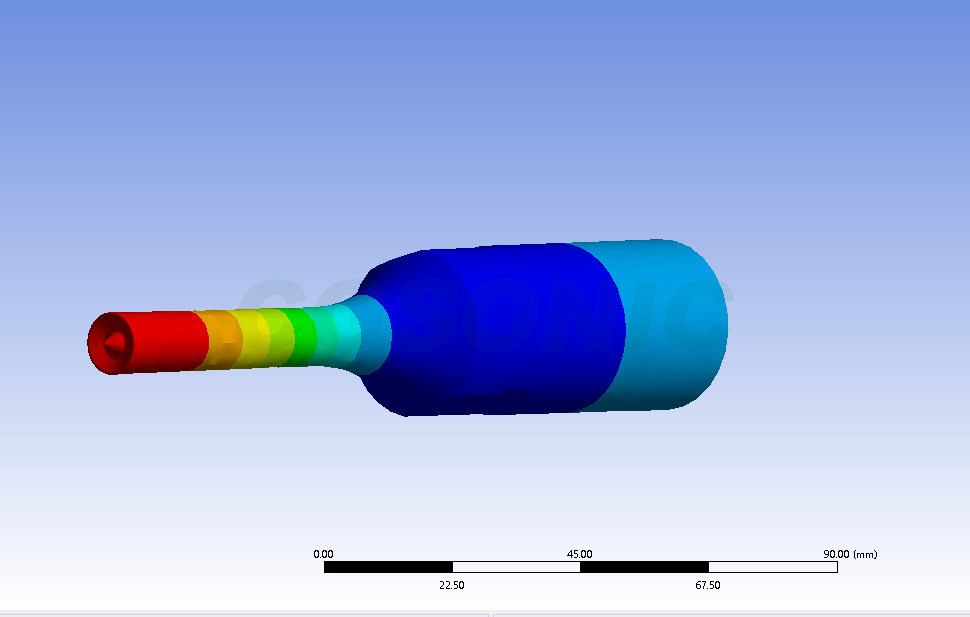

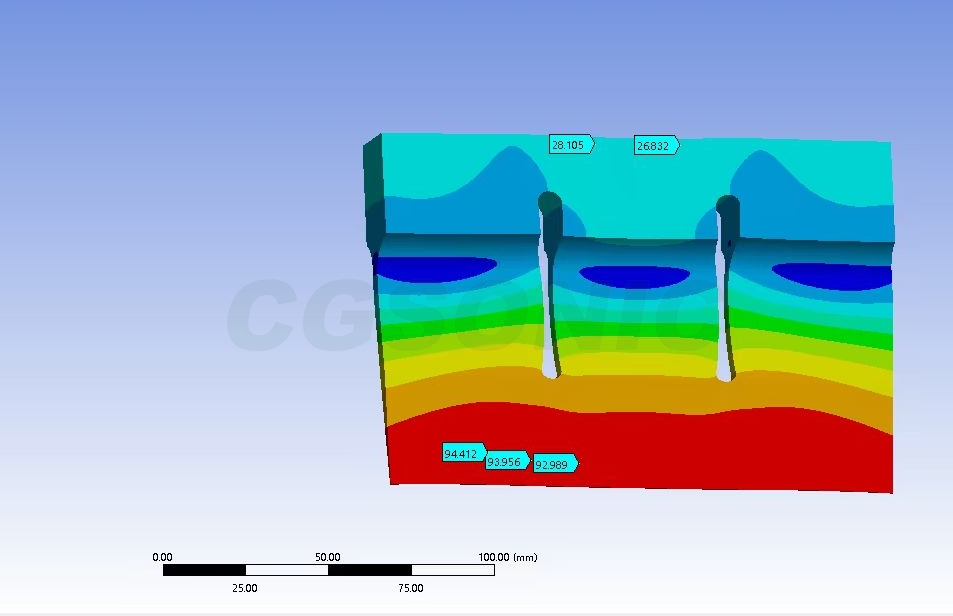

With years of experience in ultrasonic technology research and development, CGSONIC has now achieved full customization of Horn products. Whether it is a complex curved surface, an irregular structure, or a special material (such as titanium alloy, aluminum alloy, steel , etc.), CGSONIC can ensure that the product reaches the industry's top level in amplitude, frequency and durability through precision machining and simulation optimization.

- Efficient and rapid response to customer needs , seamless integration from drawings to finished products.

The client only needs to provide the following information:

- Product Images: Key dimensions and material requirements for standard products are clearly marked;

- 3D drawings: Supports STEP, STP, STL and other formats;

- Parameter list: including frequency (15kHz-40kHz), amplitude, welding requirements ( waterproofing required, etc. ).

- Customer sends samples;

CGSONIC's engineering team will complete the solution evaluation within 48 hours and provide welding solutions and production cycle estimates to achieve "zero error" delivery.

- Wide range of applications, empowering upgrades across multiple industries

Customized Horns can be widely used in:

-Automotive Industry Spot welding of car door panels and spot welding of automotive interior sound insulation cotton ;

- Electronics Manufacturing Charger adapter soldering, headphone shell, speaker shell ;

- Medical equipment Disposable medical protective clothing and masks;

- Packaging industry : Sealing the ends of plastic tubes for cosmetics and toothpaste tubes;

- Food industry: Food cutting;

Through optimized material and structural design, CGSONIC helps customers increase production efficiency by more than 30% while reducing energy consumption by 15%.

A global automotive parts supplier reported: "CGSONIC's custom-made titanium alloy Horn for us solved the problem of uneven welding amplitude in irregularly shaped parts, increasing the yield rate from 78.8 % to 90.2 %."

CGSONIC will continue to deepen its expertise in ultrasonic technology, driving non-standard customized services with a focus on customer needs. In the future, the company will further shorten delivery cycles to support the upgrading of intelligent manufacturing. CGSONIC (Chengguan Ultrasonic) has focused on the R&D and production of ultrasonic equipment for over 20 years , delivering professional equipment and services to more than 60 countries worldwide, continuously empowering the efficient development of various industries , with technology as its core and quality as its foundation .