The design concept of ultrasonic welding ribs

2025-10-09

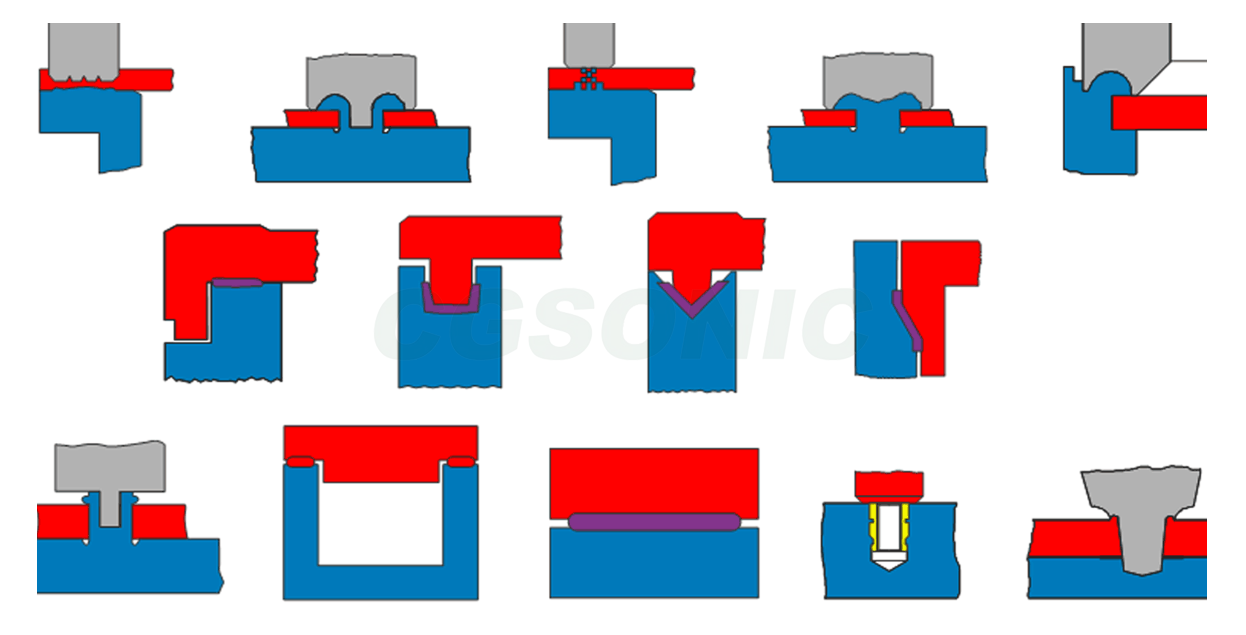

The design concept of ultrasonic welding ribs: Ultrasonic welding ribs (also known as energy-directed ribs) are the core structural design in ultrasonic plastic welding. Their function is to concentrate the ultrasonic vibration energy through the raised structure, causing rapid generation of friction heat and melting in the local area, ultimately achieving a firm connection between the two components. The design needs to focus on the efficiency of energy concentration, welding strength, sealing performance, material compatibility, and process feasibility. The specific ideas are as follows:

- Define the welding target and constraints: Before designing, it is necessary to first define the core requirements to avoid blind design.

- Selection of welding rib types: Based on the target requirements and product structure, select the appropriate type of welding rib.

- Key dimension design (core parameters): The dimensions need to balance "energy concentration" and "welding filling". Being too large may lead to flash / energy dispersion, while being too small may result in insufficient welding.

- Layout design: Ensure uniform energy distribution: 1. Continuously distributed along the joint surface; 2. Adapt to the product structure; 3. Cooperate with the "stop structure".

- Adaptation of materials and process characteristics: 1. Adjust material compatibility; 2. Injection molding feasibility.

- Verification and optimization