The function of ultrasonic welding wires

Core Functions

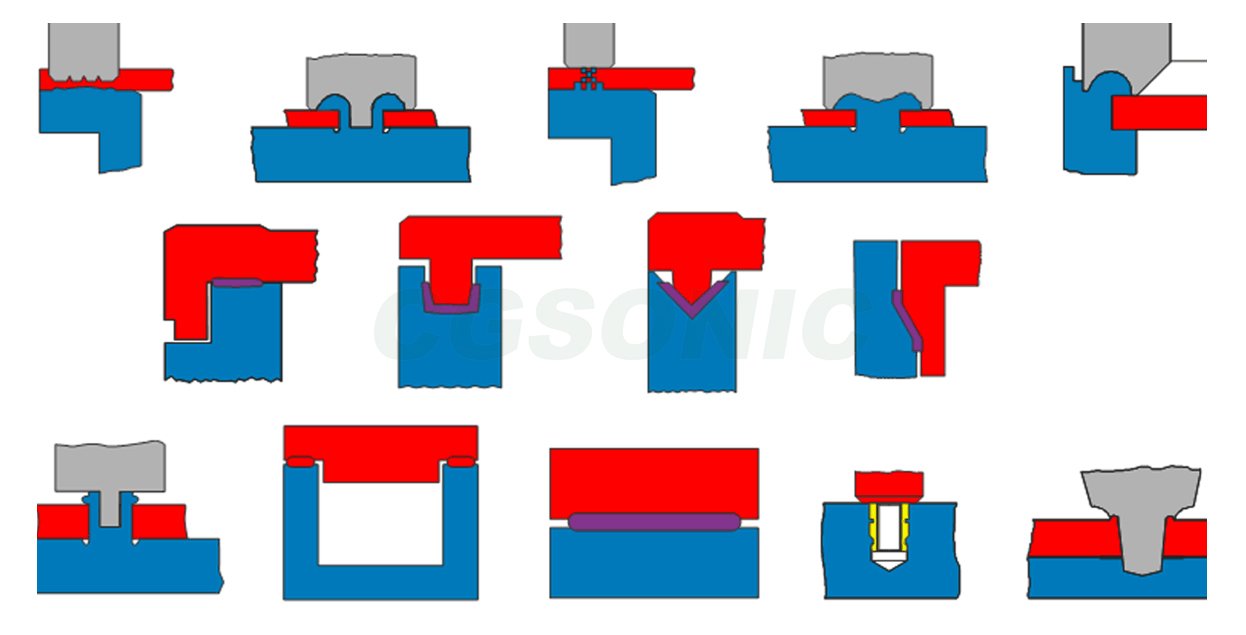

Energy Focusing: The ultrasonic lines are small, raised lines designed on the contact surface of plastic parts. They concentrate the dispersed ultrasonic vibration energy onto themselves, rapidly generating high temperatures.

Melting Control: The high temperature melts the ultrasonic lines first. The molten plastic fills the gaps at the contact surface, preventing excessive molten material from overflowing and ensuring a smooth weld surface.

Enhanced Sealing: The molten plastic fully fuses under pressure, forming a gapless connection and improving the waterproof and gas-proof sealing performance of the weld.

Key Design Considerations:

Dimensions: Typically 0.2-0.5mm wide and 0.1-0.3mm high, but adjustments may be needed based on the hardness of the plastic material.

Location: Must correspond to stress points on the welding surface or critical sealing areas to ensure even force and energy transfer.