The key points for achieving seamless and sealed plastic welding with ultrasonic welding machines

Compatible with plastic materials and structural design

Give priority to thermoplastic materials such as ABS, PC and PMMA that have strong compatibility for ultrasonic welding, and avoid flexible materials like

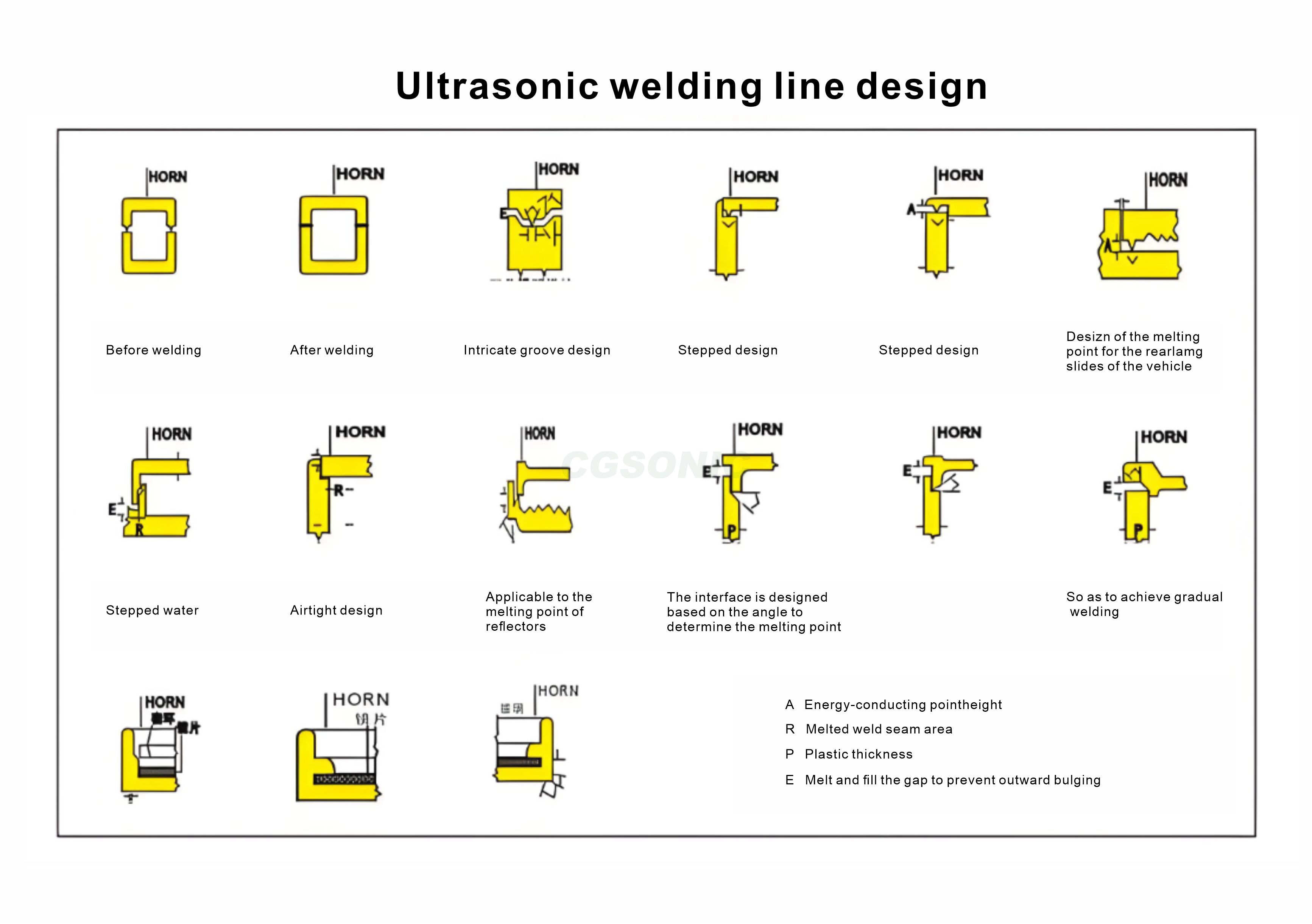

PE and PP (which require special processes). Structurally, it adopts a "energy-guided rib + sealing groove" design: The energy-guided rib (sharp protrusion)

concentrates ultrasonic energy for rapid melting, and the sealing groove (annular/strip-shaped groove), in combination with the molten material filling,

forms a physical sealing ring, enhancing air tightness.

Precisely control the core parameters of welding

Energy/Time: Set according to the thickness of the plastic to ensure that the molten material flows fully without overflowing, avoiding gaps caused by

incomplete melting or residues produced by overmelting. Pressure: the initial low pressure positioning the workpiece, the molten stage pressure promote

material flow filling seal groove, pressure maintaining phase voltage shape; Amplitude: through transducer matching, choose high amplitude, hard plastic

soft plastic to choose low amplitude, ensure energy evenly transfer to welding surface.

Optimize the tooling and welding process

Customize high-precision fixtures to fix the workpiece and ensure that the contact error of the welding surface is less than 0.1mm. The "pre-pressing + stepwise

welding" process is adopted. First, the gap is eliminated by low energy, and then the energy is gradually increased to achieve molten sealing. For complex curved

surfaces, multi-station rotary welding or custom profiling welding heads are adopted to ensure uniform force distribution on the welding surface.