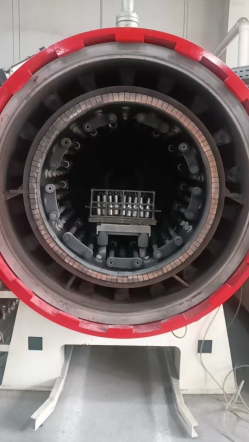

Ultrasonic welding molds are processed in a dedicated vacuum heat treatment furnace.

Ultrasonic molds and ultrasonic steel molds are core components of ultrasonic welding equipment, and their surface precision, hardness, and wear resistance directly determine the welding quality. In the steel mold manufacturing process, vacuum heat treatment in a dedicated furnace is a key step in improving the performance of the steel mold. Shenzhen Chengguan Intelligent Ultrasonic Co., Ltd. (hereinafter referred to as "Chengguan Intelligent"), as a professional supplier of ultrasonic welding equipment and molds in China, has achieved a dual breakthrough in the precision and lifespan of steel molds through customized vacuum heat treatment furnace processes.

I. Core Requirements of Ultrasonic Steel Molds for Heat Treatment

Ultrasonic steel molds are typically made of mold steel (such as SKD11, DC53) and need to withstand high-frequency vibration, friction, and impact, therefore they have strict requirements for heat treatment.

- High hardness : The surface hardness needs to reach HRC58~62 to ensure wear resistance;

- Low deformation : The precision of the steel mold must be controlled within 0.01mm, and the deformation after heat treatment must be <0.005mm;

- Oxidation-free : The surface of the steel mold must be kept smooth to avoid affecting the accuracy during subsequent grinding.

Traditional heat treatment can easily lead to oxidation and excessive deformation of steel molds, while Chengguan Intelligent uses a customized vacuum heat treatment furnace , which perfectly matches these needs.

II. Customized Configuration of Chengguan Intelligent Vacuum Heat Treatment Furnace

To accommodate the small size and high precision characteristics of ultrasonic steel molds, Chengguan Intelligent, in collaboration with equipment manufacturers, customized a small precision vacuum heat treatment furnace with the following core configuration:

- Furnace parameters : effective size φ200×300mm, suitable for batch processing of 10~15 steel molds per batch;

- Vacuum system : A molecular pump unit is used to maintain a stable vacuum of 5×10⁻³Pa, thus preventing oxidation of the steel mold surface;

- Temperature control system : 4 independent temperature control zones, temperature uniformity ±1℃, ensuring consistent hardness in all areas of the steel mold;

- Cooling system : staged gas quenching (first rapid cooling with 1MPa nitrogen, then slow cooling with 0.3MPa) to reduce thermal stress deformation.

III. Process Flow of Ultrasonic Steel Mold Vacuum Heat Treatment Furnace (Chengguan Intelligent Practice)

Chengguan Intelligent integrates vacuum heat treatment into the entire steel mold manufacturing process. The specific steps are as follows:

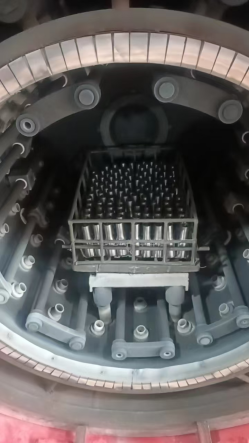

1.charging the furnace, the steel mold is prepared by CNC machining, and the surface oil and burrs are cleaned. It is then clamped using a graphite clamping fixture

customized by Chengguan Intelligent (to avoid the steel mold sticking to the clamping fixture) and evenly arranged on the furnace charge tray.

2.vacuuming and heating , and closing the furnace door, first evacuate to a low vacuum (10⁻¹Pa) to remove air, then raise the vacuum to the target level (5×10⁻³Pa); heat to 850℃

at a rate of 5℃/min and hold for 20min (to meet the austenitization requirements of SKD11 material).

3.Vacuum quenching is performed by rapidly cooling the steel mold with 1MPa high-purity nitrogen gas, reducing the temperature from 850℃ to 200℃ (cooling rate 15℃/s). Then,

the temperature is switched to 0.3MPa nitrogen gas for slow cooling to room temperature to avoid stress concentration.

4.vacuum tempering and quenching, the steel mold is put back into the special furnace, heated to 200℃, and held for 60 minutes to eliminate quenching internal stress and stabilize

the dimensions of the steel mold (Chengguan Intelligent controls the deformation of the steel mold to within 0.003mm through this process).

5.the furnace , the steel mold surface is bright and free of oxidation. After passing the hardness test (HRC60±1) and precision test (3D scanner), it enters the subsequent polishing process.

6.IV. The Technical Value of Vacuum Heat Treatment in Dedicated Furnaces (Chengguan Intelligent Case Study)

Through a customized vacuum heat treatment furnace process, Chengguan Intelligent's ultrasonic steel mold has achieved:

- Extended lifespan : The average service life of steel molds has been increased from 50,000 welding cycles in the traditional process to 120,000 cycles;

- Stable precision : The repeatability of the steel mold is maintained within 0.01mm, and the yield of welded products is improved to 99.5%;

- Cost reduction : The reduction in subsequent grinding and rework processes has lowered the manufacturing cost of a single steel mold by 15%.

As a technology-driven enterprise in the field of ultrasonic welding, Chengguan Intelligent has deeply integrated vacuum heat treatment furnace technology

into steel mold manufacturing through an integrated layout of "equipment + mold + process", providing more reliable ultrasonic welding solutions for industries such as electronics, textiles, and automobiles.