OEM Metal-Plastic Joining Solutions | Trusted Manufacturer & Supplier

As a leading player in Metal-Plastic Joining technology, we specialize in providing top-notch ultrasonic equipment tailored for various industries. Our products are CE Certified, ensuring that you receive nothing but the highest quality and compliance with international standards. I have visited multiple factories and understand the unique needs of suppliers like you, making us an ideal partner for your projects

Must-Know Tips For Metal-Plastic Joining Dominates Guarantees Peak Performance

In the rapidly evolving landscape of manufacturing, metal-plastic joining techniques have become crucial for ensuring optimal product performance. As industries strive for lightweight, durable materials, understanding the intricacies of ultrasonic plastic welding becomes paramount. This process not only ensures a robust bond between dissimilar materials but also enhances production efficiency, reducing cycle times and energy consumption. When considering metal-plastic joining, it's essential to focus on critical factors such as material compatibility, joint design, and process parameters. Utilizing advanced ultraSonic Welding systems can significantly mitigate issues related to heat distortion and contamination, which are often pitfalls in traditional joining methods. Moreover, with proper training and expertise in the use of ultrasonic equipment, procurement teams can achieve higher quality standards, ensuring that the end products meet both performance and safety regulations. Ultimately, investing in state-of-the-art ultrasonic welding technology and adhering to best practices in metal-plastic joining will lead to superior product durability and reliability. This not only improves customer satisfaction but also positions companies for success in a competitive global market. By prioritizing these must-know tips, businesses can unlock the full potential of their manufacturing processes and drive innovation forward.

Must-Know Tips For Metal-Plastic Joining Dominates Guarantees Peak Performance

| Tip | Description | Benefits |

|---|---|---|

| Surface Preparation | Clean and roughen the surfaces to improve adhesion. | Enhances bonding strength and durability. |

| Choosing the Right Adhesive | Select adhesives specifically designed for metal-plastic combinations. | Ensures optimal performance and longevity of the joint. |

| Temperature Considerations | Control the temperature during joining to avoid stress and damage. | Prevents thermal expansion and contraction issues. |

| Proper Curing Time | Allow sufficient time for adhesives to cure fully before use. | Maximizes bond strength and reduces the risk of failure. |

| Testing Joint Strength | Conduct tests to ensure the integrity of the bond. | Identifies potential weaknesses before full-scale implementation. |

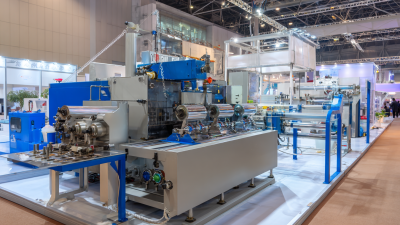

Premier Metal-Plastic Joining Application Market Leader

A

Aria Wood

So satisfied with my purchase! The staff demonstrated a level of expertise that is rare.

07 July 2025

N

Noah Gray

Impressive quality and the service team was incredibly helpful! Highly recommended.

21 May 2025

M

Mia Lee

Incredible product! Their after-sales team provided excellent and timely assistance, which I truly appreciate.

18 June 2025

L

Luke Phillips

The quality truly stands out! The support team was not only professional but also very friendly.

21 June 2025

S

Sebastian Johnson

Great investment! The product quality and professional after-sales support make it a win.

21 May 2025

M

Madelyn Baker

One of my best purchases! The quality is impressive, and the service team is incredibly professional.

16 June 2025