Metal Weld CE Certification: Trusted Exporters & Suppliers for Quality

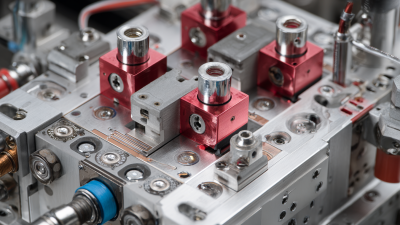

When I think about reliable Metal Weld solutions, high-quality products always come to mind. At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we pride ourselves on being a trusted factory and supplier for all your metal welding needs. Our specialized ultrasonic equipment ensures precision and durability, making every weld strong and dependable, As a professional in the industry, I understand the importance of having suppliers that you can count on. Our commitment to quality means that you’ll receive metal weld equipment designed for excellence, streamlining your production processes. With years of experience, we are dedicated to providing top-notch solutions tailored to your specifications, Partnering with us means gaining access to cutting-edge technology and a team that’s ready to support your business goals. Let’s elevate your manufacturing capabilities together with the best in metal weld equipment

Simple Ways To Metal Weld Where Innovation Meets 2025 Stands Out

Metal welding is evolving rapidly, and as we approach 2025, innovative approaches are becoming essential for businesses looking to enhance their production capabilities. One simple yet effective method to revolutionize your metal welding operations is through ultrasonic technology. This cutting-edge technique can significantly improve efficiency and precision, making it an ideal choice for industries ranging from automotive to aerospace. UltraSonic Welding utilizes high-frequency sound waves to create a bond between materials, providing a clean and strong result without the need for additional adhesives or chemicals. The process is not only faster than traditional welding methods but also reduces energy consumption and minimizes waste, aligning perfectly with sustainability goals. For manufacturers seeking to streamline their operations, investing in ultrasonic welding systems can lead to substantial cost savings and increased productivity. As global procurement trends shift towards more sustainable and innovative solutions, incorporating ultrasonic technology into your metal welding processes can set your business apart in a competitive market. By embracing these advancements, you can enhance product quality, reduce turnaround times, and ultimately meet the evolving demands of your customers in 2025 and beyond. Explore how simple innovations today can lead to significant benefits tomorrow.

Simple Ways To Metal Weld Where Innovation Meets 2025 Stands Out

| Method | Description | Advantages | Disadvantages | Cost (USD) |

|---|---|---|---|---|

| MIG Welding | A welding process that uses a continuous wire feed as an electrode and a shielding gas. | Fast process, minimal slag, suitable for thin materials. | Less effective on thicker materials, requires clean surfaces. | 500 - 1500 |

| TIG Welding | A process using a non-consumable tungsten electrode to produce the weld. | Highly precise, great for thin materials, produces clean welds. | Slower process, requires more skill. | 700 - 2000 |

| Stick Welding | A process where an electric arc forms between a stick electrode and the metal. | Versatile, can be used outdoors, works well on rusty or dirty materials. | Produces a lot of spatter and slag, less ideal for thin materials. | 300 - 1000 |

| Flux-Cored Welding | A variant of MIG welding that uses a hollow wire filled with flux. | Good for thick materials, can weld outdoors. | Less visually appealing welds, requires more cleanup. | 400 - 1200 |

| Laser Welding | Uses a laser beam to melt and join materials. | Very precise, minimal heat affected zone, fast process. | High cost of equipment, requires skilled operators. | 5000 - 15000 |

10 tips Metal Weld Manufacturers You Can Rely On Ahead of the Curve

C

Chloe Hernandez

An excellent purchase! The support staff handled my inquiries with professionalism and care.

29 June 2025

G

Grace Hughes

I absolutely love this product! The professionalism and courtesy of the service team were impressive.

17 June 2025

R

Riley Rogers

I am very pleased! The product is stable and the after-sales service was professional and insightful.

19 May 2025

S

Samantha Torres

Pleased beyond measure! The quality of the product and the support staff astounded me.

18 June 2025

A

Avery Campbell

Impressive! The after-sales support team provided guidance that was both professional and timely.

21 May 2025

L

Landon Bell

A fantastic experience! The quality is evident, and the support team exemplifies professionalism.

02 July 2025