News

Big News! HS SONIC will be exhibiting at the Mexico Industrial Equipment Exhibition in September to explore new opportunities in ultrasonic technology

From September 2nd to 4th, 2025, the Mexico City Exhibition Center will host the Industrial Equipment and Parts Network (IEPN), a major industry event. As the official distributor of HS SONIC in China and Guangdong , Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. warmly welcomes HS SONIC to the exhibition.

Chengguan Ultrasonic Welding Machine: Innovative Application and Process Breakthrough in Automobile Door Panel Welding

As an important component of the automobile body, automobile door panels must take into account structural strength, sealing performance and appearance smoothness. Their welding process has long faced three major challenges: traditional arc welding can easily lead to deformation of the door panel surface and an excessively large heat-affected zone; glue bonding has problems such as long curing time and insufficient environmental protection; mechanical riveting is prone to stress concentration, affecting overall durability.

Deepen technical cooperation and explore the forefront of the industry - the head of Chengguan Intelligent Ultrasonics visited Russia in August to have in-depth exchanges with customers

In early August 2025, the technical director of Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. (hereinafter referred to as "Chengguan Intelligent Ultrasonic") traveled to Russia for a week-long technical visit and business negotiations with key local customers. The purpose of this visit was to strengthen technical cooperation between the two parties, conduct in-depth discussions on innovative solutions for the use of ultrasonic equipment in industrial applications, and lay a more solid foundation for future long-term cooperation.

Ultrasonic welding vs. heat-sink welding: Key differences to help you choose the right technology

In modern manufacturing, welding is a key technology for achieving reliable material connections. Ultrasonic welding and heat-seal welding are two mainstream solutions for welding thermoplastics and thin films. Each method, with its distinct technical characteristics, plays an important role in different application scenarios. This article will delve into the core differences between the two methods to help you choose the right welding method.

Grateful for colleagues, warm companionship - Chengguan Intelligent Ultrasonics staff birthday party conveys humanistic care

On July 25th, Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. ( CGSONIC) held a heartwarming birthday party for employees whose birthdays fell in July . Themed "Gratitude for Colleagues, Warm Companionship," the event not only allowed employees to feel the warmth of home amidst their busy schedules but also highlighted the company's people-oriented philosophy of care.

Chengguan ultrasonic sewing machine was launched, ushering in technological innovation in the sewing industry

Inthe fields of textile, clothing , household goods and medical production, traditional sewing technology has long faced pain points such as loose stitches, difficulty in sewing thick materials, and limited production efficiency. As the market's requirements for sewing accuracy, durability and production speed continue to increase , Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. has developed a new sewing machine that integrates ultrasonic technology, bringing a breakthrough solution to the industry .

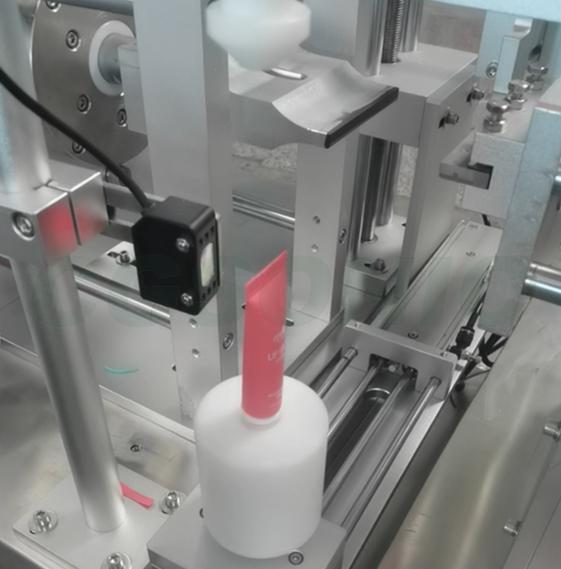

Chengguan ultrasonic hose sealing machine: efficient sealing, opening a new "clean" packaging world

As the packaging industry continues to see a surge in demand for high-efficiency, low-energy, and high-quality sealing technology, a new ultrasonic sealing machine that integrates cutting-edge technology has emerged. It not only provides a disruptive solution to the industry's pain points, but also reconstructs the logic of packaging operations with breakthrough technology, which can fundamentally change the traditional production model , improve efficiency, and save more time costs.

Chengguan Intelligent Ultrasonics obtains the agency rights of HS SONIC to jointly promote the upgrade of industry services

On May 21, 2025, the Chinese branch of Hs Sonic Inc. of the United States, HiSilicon (Guangdong) Ultrasonic Technology Co., Ltd., successfully held a signing ceremony for global agent service providers in Guangdong. Dr. ZESHAN ABBAS, head of the Asia-Pacific region of Hs Sonic, was present at the event to issue authorization certificates to a number of high-quality agent service providers. This event marks the further deepening of HiSilicon Ultrasonic's global service network. The company will empower global plastic welding industry customers with "smarter equipment and more professional services" to accelerate the process of industrial upgrading.

From manufacturing to "smart" manufacturing, Chengguan ultrasonic welding technology injects innovative power into the injection filter industry

Traditional processes are often plagued by problems such as insufficient welding precision, low efficiency and unstable sealing. Ultrasonic welding uses high-frequency vibration to partially melt and fuse thermoplastic components without the need for adhesives. This not only reduces the risk of contamination, but also achieves micron-level precision welding, ensuring the sealing integrity of the filter and preventing liquid leakage and impurity infiltration.

Chengguan ultrasonic welding technology: the best choice in power bank manufacturing, showing significant advantages

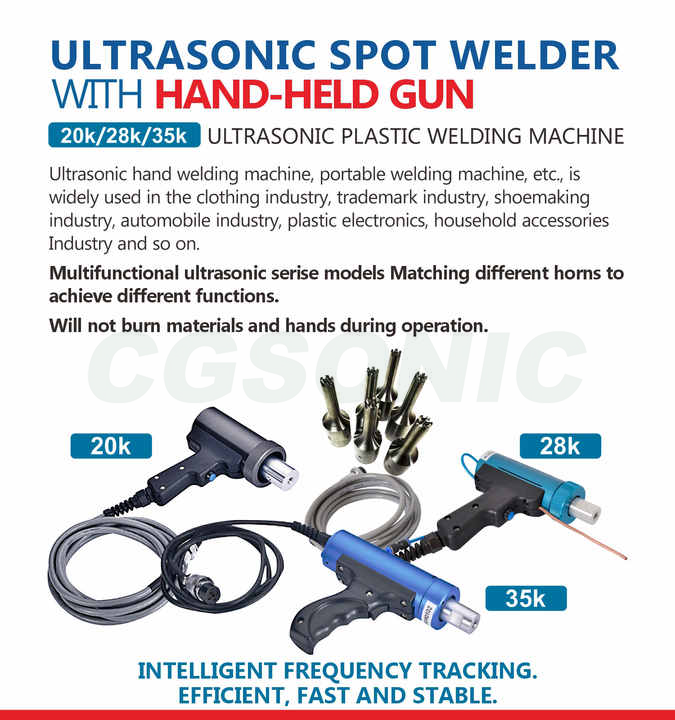

From the perspective of process principle, Chengguan ultrasonic welding technology uses high-frequency vibration (usually between 15k20k28k30k35k40k ) to quickly rub the contact surfaces of thermoplastic parts such as power bank shells under pressure, generating heat, thereby achieving instant melting of local materials and ultimately forming a strong intermolecular bond. This process does not require the addition of any adhesives, solder or other consumables, greatly simplifying the production process.