News

Chengguan ultrasonic welding technology innovates the automotive lighting manufacturing industry

In the modern era of rapid development of automobile manufacturing, the manufacturing process of headlights, as the core components of vehicle safety and aesthetics, is undergoing revolutionary changes. Chengguan ultrasonic welding technology is gradually becoming the preferred welding solution for high-end automobile manufacturers with its high efficiency, precision and environmental protection. This innovative technology has greatly improved the sealing and durability of headlight products .

Chengguan Ultrasonic Welding Technology: Reconstructing the high-end and efficiency revolution of cosmetic packaging manufacturing with the power of technology

In the field of cosmetics packaging, Chengguan, relying on 20 years of technological accumulation, leads the innovation of precision manufacturing with ultrasonic welding technology. Its glue-free, high-precision and environmentally friendly welding process can meet the high-end needs of product shell aesthetics, sealing and durability. Compared with traditional gluing or hot-melt methods, it has significant advantages and is becoming a new choice for smart packaging solutions for global beauty brands.

Chengguan ultrasonic welding technology enables electrical plug welding to start a new journey of high efficiency and reliability

The welding quality of electrical plugs directly affects the safety and reliability of electrical appliances. Traditional soldering, laser welding and other processes have problems such as low efficiency, high cost, and easy oxidation of welding points. The emergence of Chengguan ultrasonic welding technology provides a more efficient and reliable solution for this field.

Chengguan ultrasonic welding machine: professional-grade solution for acrylic welding

In the field of modern material processing, acrylic is widely used in advertising display, handicraft production, medical equipment and other scenarios due to its high transparency, excellent chemical stability and easy processing characteristics. In the acrylic welding process, ultrasonic welding machines stand out with their technical advantages such as no consumables, high precision, high efficiency and energy saving, and have become the preferred solution for many companies to achieve both quality and efficiency improvements.

Explore Chengguan Ultrasound: Precision Application Solutions for the Medical Industry

In the wave of rapid development of the medical industry, product quality, production efficiency and cost control are the core codes for breaking through. Among the dazzling array of technology upgrade paths, Chengguan ultrasonic welding technology is becoming a strategic tool for small and medium-sized medical device companies to achieve low-cost and high-efficiency upgrades.

Application scenarios and value of Chengguan ultrasonic cutting technology

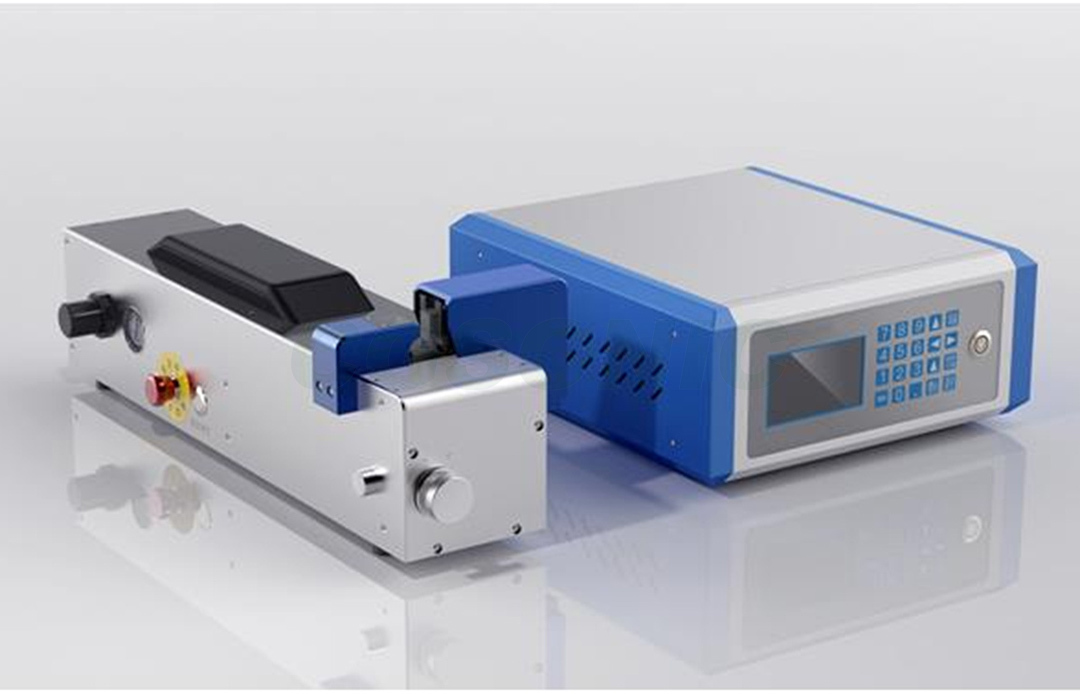

Ultrasonic cutting is a technology that uses high-frequency vibration energy to achieve material cutting. The ultrasonic generator converts electrical energy into high-frequency mechanical vibration (usually above 20kHz) and transmits it to the cutting head through the amplitude transformer, causing the cutting head to vibrate at an extremely high frequency, thereby achieving material cutting.

What process methods does Chengguan ultrasonic welding cover?

Ultrasonic welding is a technology that uses high-frequency vibration energy to make the surfaces of objects rub against each other to generate heat, thereby achieving welding. According to different welding principles and application scenarios, it can be mainly divided into the following methods:

Double breakthrough in cost reduction and efficiency improvement! Chengguan ultrasonic spot welding unlocks new possibilities in the production of automotive interior and exterior trims