Chengguan Ultrasonic Welding Machine: Innovative Application and Process Breakthrough in Automobile Door Panel Welding

As an important component of the automobile body, automobile door panels must take into account structural strength, sealing performance and appearance smoothness. Their welding process has long faced three major challenges: traditional arc welding can easily lead to deformation of the door panel surface and an excessively large heat-affected zone; glue bonding has problems such as long curing time and insufficient environmental protection; mechanical riveting is prone to stress concentration, affecting overall durability.

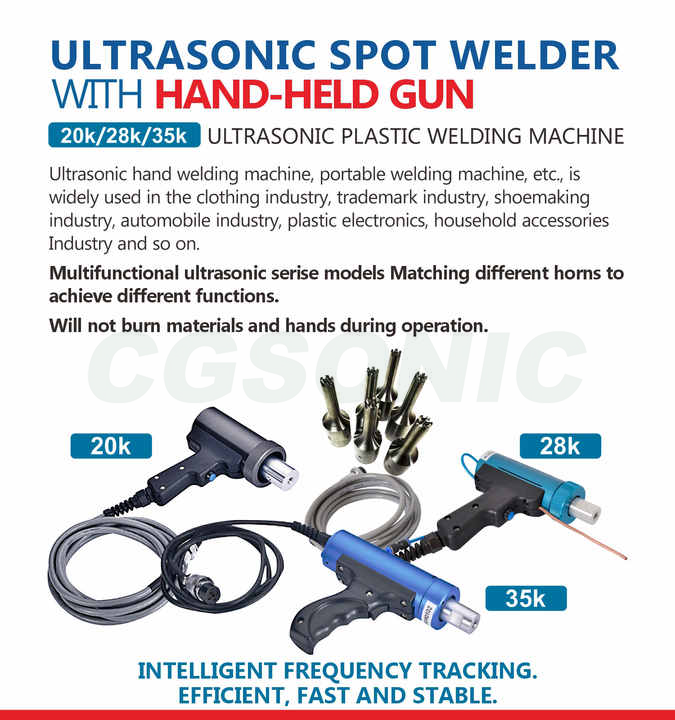

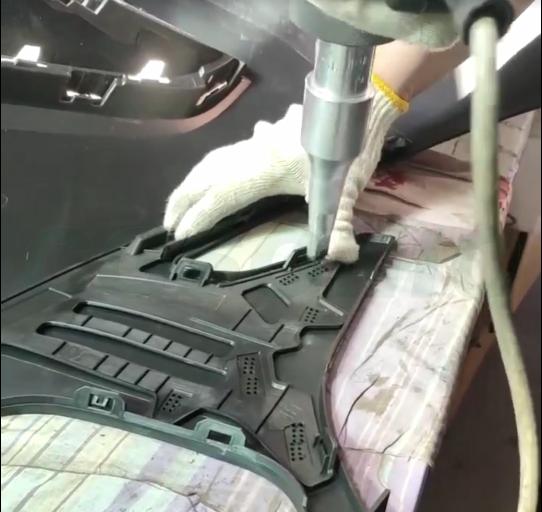

Chengguan's ultraSonic Welding machine utilizes 20kHz high-frequency vibration technology. A specialized welding head precisely focuses ultrasonic energy at the door panel joints (such as the plastic frame and metal reinforcement, or the interior panel and frame). This utilizes the localized high temperatures generated by the instantaneous friction between the contact surfaces to achieve molecular-level fusion. This process takes only 0.3-0.8 seconds per point, and the heat-affected zone is kept to less than 0.5mm, effectively avoiding the drawbacks of traditional processes.

Zero damage to the appearance: no burn marks or deformation at the welding points, meeting the stringent requirements of automobile door panels for surface finish;

30% increase in strength: According to third-party testing, the shear resistance of the weld points exceeds 1200N, far exceeding the industry standard of 800N;

Green and environmentally friendly: No consumables such as glue and welding wire are required, which reduces VOC emissions and conforms to the lightweight and low-carbon trend of new energy vehicles.

In response to the welding needs of automobile door panels with multiple materials (PP, ABS, galvanized steel plates, etc.) and multiple structures, Chengguan ultrasonic welding machines are equipped with an intelligent parameter adaptive system. It can monitor the hardness and thickness of the material in real time through sensors, and automatically adjust the amplitude, pressure and welding time to ensure the consistency of the quality of welds in different parts.

The application of Chengguan's Ultrasonic Spot Welding technology in automotive door panels has taken automotive welding processes one step further toward high precision, low energy consumption, and intelligent manufacturing. As new energy vehicles increase their demands for lightweight and safer bodies, these high-efficiency welding solutions will become a core driver of industry upgrades.

In the future, Chengguan Intelligent Ultrasonic plans to further expand the application scenarios of its technology and develop specialized welding equipment for components such as automotive dashboards and bumpers, continuously injecting innovative momentum into the automotive manufacturing industry.