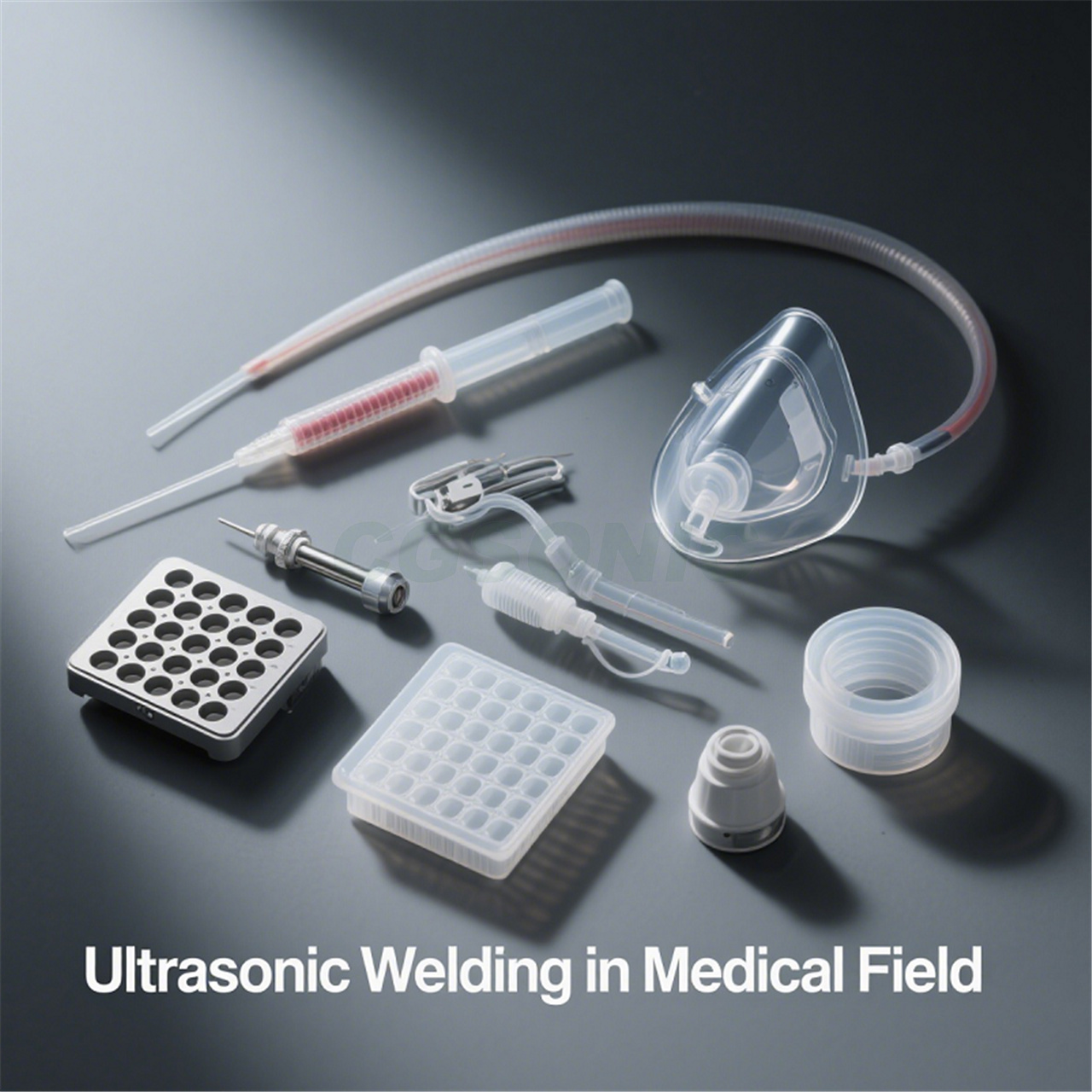

Explore Chengguan Ultrasound: Precision Application Solutions for the Medical Industry

In the wave of rapid development of the medical industry, product quality, production efficiency and cost control are the core codes for breaking through. Among the dazzling array of technology upgrade paths, Chengguan Ultrasonic Welding technology is becoming a strategic tool for small and medium-sized medical device companies to achieve low-cost and high-efficiency upgrades. This innovative process, with its non-contact welding characteristics, significantly improves production efficiency while ensuring the precision and cleanliness of medical products; its digital control mode can accurately match the welding requirements of different materials and structures, saving companies unnecessary consumables and labor costs in traditional processes. For small and medium-sized medical device companies that pursue refined operations, Chengguan ultrasonic welding is not only a technological innovation on the production line, but also an important engine for breaking through homogeneous competition and building differentiated advantages.

1. What is ultrasound?

Ultrasonic waves are sound waves with a frequency higher than 20,000 Hz, which is beyond the range of human hearing (20 Hz~20,000 Hz). They have the characteristics of good directionality, strong penetration, and easy acquisition of concentrated sound energy. Ultrasonic welding has become one of the key technologies in the medical field due to its high efficiency, cleanliness, and precision.

2. Advantages of ultrasonic technology in the medical field:

- Non-contact welding avoids contamination and meets medical-grade cleanliness standards;

- Fast welding speed (millisecond level), suitable for automated production lines, reducing labor costs;

- Can weld complex geometric shapes to adapt to personalized medical device design (such as porous structures, thin-walled pipes);

- It can weld micro-tubes with a diameter of ≤1mm, avoiding deformation or blockage of the tube opening caused by traditional heat welding (such as the tiny catheter of the insulin pump).

- Material compatibility: weldable PE, PP, PVC, silicone, metal-Plastic composite materials, etc., to meet the diverse material needs in the medical field.

- Used for precise cutting of medical polymer materials (such as silicone and rubber), with smooth incisions without burrs, and reducing material loss (such as segmented processing of surgical blades and catheters).

3. Application scenarios of ultrasonic welding:

- Seamless welding of medical catheters (such as infusion tubes, urinary catheters), dialyzers, blood bags and other polymer material products to avoid biocompatibility risks caused by glue residues.

- Welding of breathing and anesthesia equipment: anesthesia masks, ventilator tubes, oxygen humidification bottles, nebulizer components, etc.;

- Welded catheter devices: angiography catheters, balloon catheters, stent delivery systems, ablation catheters, etc.

- Precision welding of micro medical devices (such as insulin pump components and neurostimulator housings) ensures compact structure and sealing.

- Sterile packaging sealing: sterile packaging bags for surgical instruments, sterile trays for implants, blister packaging for disposable syringes, etc.

As the medical industry continues to increase its requirements for equipment precision, safety, and sterility, Chengguan Ultrasonic has a bright future. With its non-contact, clean and efficient, and precise and controllable characteristics, it helps minimally invasive interventional devices achieve reliable connection of multi-layer composite structures and precise welding of small diameters in the welding of medical polymer consumables; meets the high-precision welding requirements of packaging sealing and automation equipment components; and achieves sterile sealing of medical packaging and seamless welding of biological sample transport containers. With the continuous innovation of technology, Chengguan ultrasonic welding technology will bring better quality and efficient welding solutions to the medical field and promote the medical device industry to new heights.