Ultrasonic technology innovation ushers in a "gentle era" for plastic sprue removal.

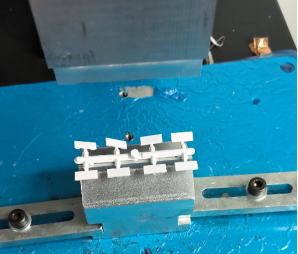

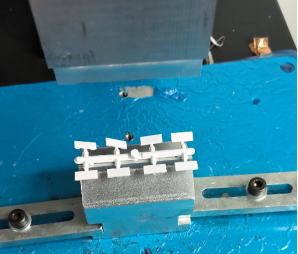

Sprue shaking equipment

Ultrasonic sprue removal technology for plastics has been successfully implemented on production lines. Utilizing a non-contact processing method based on high-frequency vibration, it replaces traditional cutting processes, precisely separating sprues while completely avoiding scratches and burrs, significantly improving the quality of plastic parts. This technology is suitable for injection molded parts of various sizes and complex shapes, offering advantages such as high efficiency, low energy consumption, and environmental friendliness. It is widely used in the automotive, electronics, and home appliance industries, helping companies reduce costs and increase efficiency, and further propelling the plastics processing industry towards intelligent and refined manufacturing.

Advantages of water inlet shaking technology

- Non-destructive separation , ensuring product precision. High-frequency vibration is used to achieve precise separation between the sprue and the product, without mechanical stress damage, and will not cause product deformation, scratches or chipping. It is especially suitable for thin-walled and precision plastic products.

- High-efficiency operation , improving production cycle: The shaking process can be completed in just a few seconds. Compared with traditional methods such as manual trimming and knife cutting, the efficiency is increased by 3-5 times. It can be seamlessly connected to automated production lines and shorten the overall production cycle.

- High consistency and stable product quality: Standardized vibration parameter settings ensure uniform sprue separation effect for each product, eliminating individual differences caused by manual operation, effectively reducing defect rate and ensuring stable batch quality.

- No consumables required , reducing production costs. No consumable materials such as blades, molds, and chemical reagents are needed; only electric power is required, reducing the cost of purchasing and replacing consumables, and also reducing the frequency of equipment maintenance.

- Environmentally friendly and clean , conforming to green production processes with no dust or debris splashing, and no chemical pollution, avoiding the waste pollution problems of traditional cutting methods, and meeting environmental protection production requirements.

- Simple operation and reduced manual labor threshold: After the equipment is debugged, only simple feeding and start-up operations are required. No professional technicians are needed, which reduces labor training costs and reduces the difficulty of job operation.

- Wide adaptability to meet diverse needs: The vibration frequency, amplitude and fixture can be flexibly adjusted according to the material, shape and sprue position of different products, making it suitable for plastic products of various processes such as injection molding and blow molding.

- Extend mold life and reduce secondary processing. Compared with the mechanical ejector pin forced separation method, ultrasonic vibration causes minimal wear to the mold and can extend the mold life; at the same time, the separated product has smooth edges and does not require secondary grinding.

In summary, ultrasonic vibration technology for removing plastic sprues has outstanding advantages such as high efficiency, environmental friendliness, versatility, and ease of maintenance. It can also achieve high-precision non-destructive separation, demonstrating great application potential and practical value in injection molding processes.