0102030405

Ultrasonic webbing welding technology enables glue-free, seamless connections, empowering upgrades across multiple industries.

2026-01-09

Ultrasonic Welding Equipment for webbingis a specialized device that uses ultrasonic vibration energy to achieve precision welding of webbing (such as nylon and polyester webbing). The following are its core concepts and applications:

I. Core Principles of the Equipment

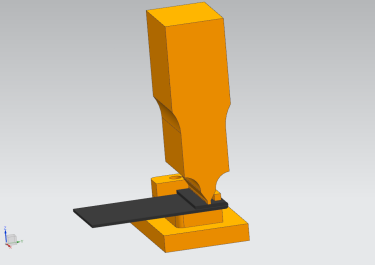

It converts electrical energy into high-frequency mechanical vibration (typically 20~40kHz) through an ultrasonic transducer , which is then transmitted to the contact area of the webbing via the Welding Head.

- Vibration and friction cause the contact surface of the webbing to heat up rapidly to the material's melting point, achieving thermal fusion bonding.

- With the specific shape of the welding head (the pointed welding head in the picture), processes such as splicing, melting, and embossing of webbing can be completed.

II. Core Advantages of Ultrasonic Welding for Ribbon

Compared to traditional needle and thread sewing and hot pressing welding, its characteristics are:

- High efficiency : Each welding operation takes only 0.5 to 2 seconds, making it suitable for mass production;

- Good strength : The tensile strength of the weld is close to that of the webbing material itself;

- No consumables : No needles, thread, or glue are needed, reducing costs;

- Good appearance : There are no pinholes or protrusions at the weld joints, and the surface is flat and beautiful.

III. Typical Application Scenarios

This type of equipment is widely used in industries that require webbing splicing/forming:

- Bags and Apparel : Backpack shoulder strap splicing, work ID lanyard, waist belt joint welding;

- Outdoor Gear : Tent ropes and straps for breakage, backpack webbing reinforcement;

- Automotive interior : Seat belt connector welding, seat webbing fixing;

- Security equipment : fire suit webbing splicing, safety rope melt sealing.

IV. Applicable Machines

- Ultrasonic plastic welding machine

-

- Ultrasonic benchtop spot welding machine

-