Plastic Spot Welder for OEM Factories and Manufacturers Solutions

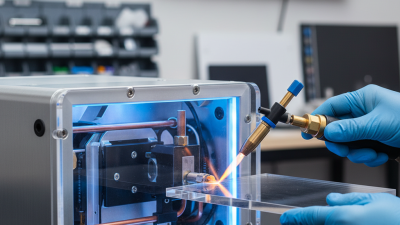

When it comes to finding the perfect solution for your manufacturing needs, our Plastic Spot Welder stands out. I’ve worked hands-on with various custom applications, and this machine is designed to meet the unique requirements of factories and manufacturers alike. Whether you’re involved in automotive, electronics, or any other sector, our welder provides reliability and efficiency, enabling you to boost production rates while maintaining high-quality standards, What I appreciate about our Plastic Spot Welder is its versatility. It easily adapts to different materials, allowing for tailored solutions that fit your specific projects. Plus, with support from our team at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., you can expect top-notch service and expertise. Don’t just settle for standard equipment; invest in a machine that enhances your operations and meets your unique needs. Let’s elevate your manufacturing process together!

Reasons to Choose Plastic Spot Welder Pioneers in the Field Now Trending

In today's fast-paced manufacturing landscape, the significance of robust and efficient welding solutions cannot be overstated. Plastic spot welders have emerged as essential tools across a variety of industries, offering precision and reliability that streamline production processes. As companies seek innovative solutions to enhance their operations, the emergence of pioneers in ultrasonic plastic welding technology presents a compelling reason to consider these advanced systems. With 20 years of dedicated research and development, these industry leaders are at the forefront of delivering unparalleled ultraSonic Welding systems tailored to meet diverse needs. One of the primary reasons to choose ultrasonic plastic welders is their ability to enhance production efficiency. Unlike traditional methods, ultrasonic welding allows for quick and precise bonding of plastics, significantly reducing cycle times. This technology not only minimizes energy consumption but also improves product quality by ensuring strong, uniform joints with minimal thermal deformation. Industries ranging from automotive to consumer goods are increasingly turning to ultrasonic solutions to stay competitive and responsive to market demands. Moreover, the versatility of ultrasonic welding equipment enables manufacturers to tackle a wide array of applications, from intricate lace bonding to robust cutting procedures. Incorporating such advanced technology not only enhances operational capabilities but also empowers businesses to innovate and evolve their product offerings. By choosing ultrasonic plastic welders, companies can not only optimize their manufacturing processes but also position themselves at the cutting edge of industry trends, ensuring they are well-equipped to meet the challenges of tomorrow.

Reasons to Choose Plastic Spot Welder Pioneers in the Field Now Trending

| Feature | Benefit | Reason for Popularity |

|---|---|---|

| High Precision | Ensures strong and reliable joints | Demand for quality in manufacturing |

| Energy Efficient | Reduces electricity costs | Growing focus on sustainability |

| User-Friendly Design | Minimizes training time for operators | Increased efficiency in production lines |

| Versatile Applications | Can be used on a variety of plastic types | Adaptability to different market needs |

| Compact Size | Saves space in manufacturing facilities | Ideal for small to medium production settings |

Best Methods To Plastic Spot Welder Sets the Industry Standard Guarantees Peak Performance

O

Olivia Taylor

This purchase was worth every penny! The after-sales service team demonstrated professionalism and quick problem-solving skills.

15 June 2025

E

Ella Davis

The quality is amazing! The after-sales team was responsive and genuinely cares for their customers.

01 June 2025

A

Avery Scott

I’m very satisfied with this product! The after-sales service showed fantastic professionalism and expertise.

28 May 2025

G

Gabriel Foster

Simply put, great quality! The after-sales service was attentive and professional.

14 June 2025

E

Emily Reed

Wonderful item! The customer service was exceptional and made me feel valued.

30 May 2025

C

Carter Ward

Outstanding experience! The quality stands out, and the staff was highly professional and helpful.

24 May 2025