High-Quality PVC Sewing Machines from Top Manufacturers & Suppliers

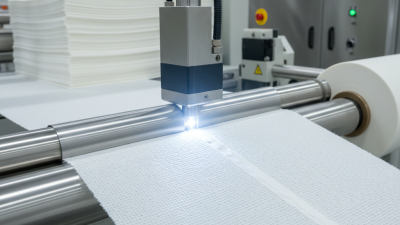

As a manufacturer, I understand the importance of quality and efficiency in your production process. That’s why I’m excited to present our top-of-the-line Pvc Sewing Machine, designed for factories and suppliers who demand precision and reliability. Whether you're looking to create durable products or enhance your production capabilities, our machine caters to all your needs, With its advanced ultrasonic technology, it can easily handle various PVC materials, ensuring strong and lasting seams without wasting time on tedious manual work. I believe in building strong partnerships, so I can offer you the best wholesale pricing to support your business growth, At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we prioritize your satisfaction, and our experienced team is always ready to assist you with any inquiries. Elevate your manufacturing process and choose our PVC Sewing Machine for unparalleled quality and performance. Let’s connect and explore how we can meet your specific needs!

Effective Ways To Pvc Sewing Machine Guarantees Peak Performance Stands Out

When it comes to achieving peak performance in manufacturing processes, the choice of equipment can significantly impact productivity and quality. One critical aspect often overlooked is the tooling used in ultrasonic Plastic Welding, which provides advantages that standard methods simply cannot match. The effectiveness of a PVC sewing machine is paramount, particularly in industries requiring precision and durability in their products. By integrating advanced ultrasonic technologies, manufacturers can ensure not only efficient production but also superior end results. Investing in high-quality ultrasonic welding systems allows businesses to experience faster cycle times, reduced operational costs, and enhanced product integrity. The capability of ultrasonic equipment to join materials without adhesives or mechanical fasteners leads to stronger, cleaner seams, which is crucial in demanding applications such as automotive, medical, and consumer goods. Additionally, these machines are designed for versatility, accommodating various materials and thicknesses, which can open new avenues for product development. As industries continue to evolve, the demand for innovative solutions is greater than ever. Companies committed to excellence will find that embracing state-of-the-art ultrasonic technology, such as specialized sewing machines, not only meets current production standards but also sets them apart in the global market. Adopting these effective methodologies ensures that businesses can maintain a competitive edge while delivering high-quality products that stand the test of time.

Effective Ways To PVC Sewing Machine Guarantees Peak Performance Stands Out

| Feature | Description | Benefits |

|---|---|---|

| Automatic Tension Adjustment | Automatically adjusts the tension based on fabric thickness. | Ensures consistent stitching quality and reduces user error. |

| High-Speed Sewing | Can sew at speeds up to 1,000 stitches per minute. | Increases productivity for large projects. |

| Durable Feed Mechanism | Heavy-duty design to handle various materials. | Provides smooth feeding and reduces fabric slipping. |

| LED Workspace Lighting | Integrated LED lights brighten the sewing area. | Improves visibility for detailed work and reduces eye strain. |

| User-Friendly Interface | Easy-to-navigate control panel with clear instructions. | Reduces learning time for new users. |

Today's Choice of Pvc Sewing Machine From Concept to Delivery Is The Best

R

Richard Anderson

The quality of this product exceeded my expectations! The after-sales service was fantastic, and the team was incredibly knowledgeable.

01 June 2025

J

Jessica Thompson

I was thoroughly impressed by the professionalism of the support staff. They resolved my issue promptly and courteously.

03 July 2025

E

Emily Davis

The quality is unparalleled! I am also grateful for the professional assistance I received from the after-sales team.

10 May 2025

W

Wyatt Rivera

Absolutely great quality! The service team members were highly skilled and made the process easy.

30 May 2025

V

Victoria Bennett

Wonderful quality! The after-sales personnel were educated and genuinely caring.

09 May 2025

T

Tyler Anderson

Remarkable product! The customer service representatives demonstrated incredible professionalism.

20 June 2025