Wholesale Tube Sealing Machine | Leading Exporters & Manufacturers

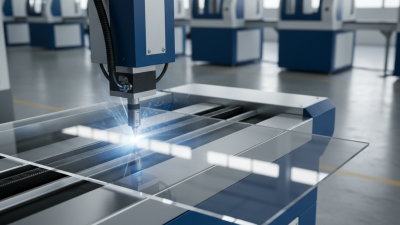

With our Tube Sealing Machine, I can guarantee enhanced efficiency for your packaging needs. Designed specifically for various industries, this machine not only seals tubes tightly but also ensures product integrity. As a reliable OEM supplier, I understand the importance of precision and durability, which is why our manufacturing process is top-notch, I'm proud to say that Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. delivers machines that meet international standards and have earned the trust of countless customers. Whether you're in cosmetics, pharmaceuticals, or food production, our Tube Sealing Machine can be customized to fit your requirements, Plus, with our strong after-sales support, you won’t just purchase a product but a commitment to your success. If you're seeking a dependable solution with excellent performance, I encourage you to consider our machine — it could revolutionize your production line and boost your efficiency!

Expert Tips For Tube Sealing Machine Industry Leaders Pioneers in the Field

In the dynamic landscape of manufacturing, tube sealing machine technology has become a key focus for industry leaders aiming to enhance efficiency and product quality. With a commitment to innovation, companies are increasingly adopting ultrasonic plastic welding solutions that streamline production processes and ensure robust sealing. This advanced technology not only improves the integrity of sealed products but also reduces energy consumption, making it an environmentally friendly option. Leaders in the tube sealing machine sector should consider investing in ultraSonic Welding systems tailored to their specific needs. These systems offer versatility across various applications, including the medical, cosmetic, and food industries, where product safety and reliability are paramount. The integration of ultrasonic technology facilitates a more precise welding process, resulting in stronger seams and less material waste. By staying ahead of technological advancements, industry pioneers can enhance their market position and deliver superior products to their customers. Furthermore, it is essential for procurement professionals to evaluate the long-term benefits of ultrasonic equipment not just in terms of immediate cost but also in terms of return on investment. The durability and efficiency of ultrasonic systems can lead to lower maintenance costs and reduced downtime, therefore optimizing production workflows. As industry leaders continue to embrace innovations in tube sealing technology, they set new standards for quality and reliability that will shape the future of manufacturing.

Expert Tips For Tube Sealing Machine Industry Leaders Pioneers in the Field

| Tip Category | Expert Tip | Implementation Strategy | Expected Outcome |

|---|---|---|---|

| Efficiency | Optimize machine speed and settings | Conduct regular performance audits | Increased production rate |

| Quality Control | Implement a four-point check system | Train staff on quality benchmarks | Lower defect rates |

| Innovation | Invest in R&D for new sealing technologies | Set aside budget for experimentation | Enhanced product capabilities |

| Sustainability | Use eco-friendly materials | Source from certified suppliers | Improved brand reputation |

| Training | Regular skill updates for operators | Create a training calendar | Higher operational efficiency |

Simple Ways To Tube Sealing Machine Where Service Meets Innovation Factory

D

David Wilson

I appreciate the attention to detail in this product. The after-sales service team was highly skilled and very approachable.

24 June 2025

M

Mia Walker

This product is exceptional in quality! Plus, the after-sales staff were well-trained and very helpful.

29 June 2025

K

Kieran Murphy

High-quality product! I was impressed by how knowledgeable and supportive the after-sales team was.

19 June 2025

E

Emily Reed

Wonderful item! The customer service was exceptional and made me feel valued.

30 May 2025

S

Sadie Allen

So impressed! The combination of quality and outstanding after-sales support made my purchase well worth it.

13 May 2025

S

Sebastian Johnson

Great investment! The product quality and professional after-sales support make it a win.

21 May 2025