- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

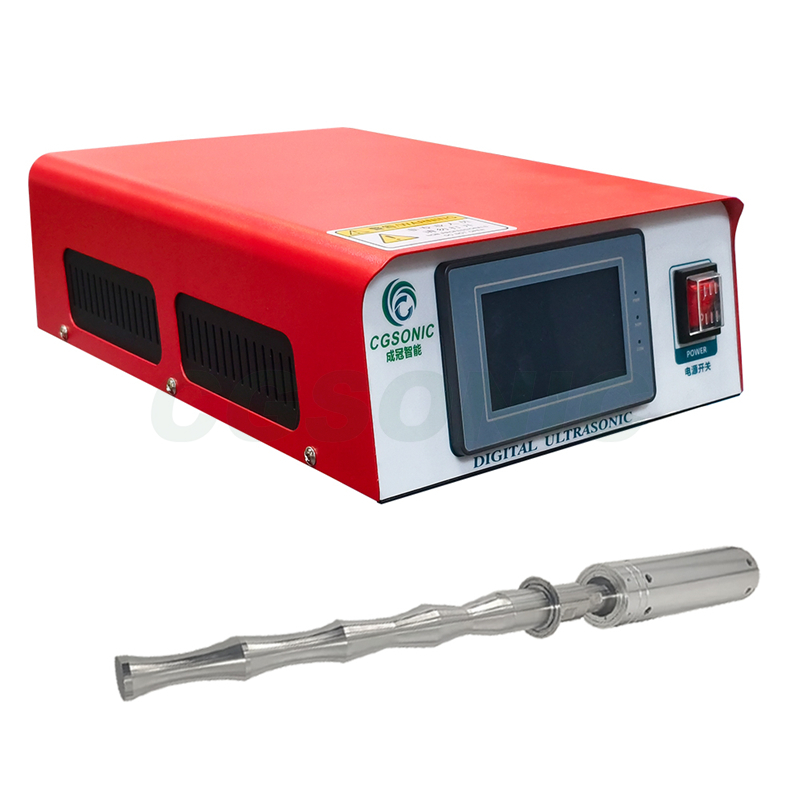

Ultrasonic cell crusher Homogenizer Ultrasonic homogenizer

Working Principle

The ultrasonic generator generates high-frequency electrical signals (usually above 20kHz), which are transmitted to the transducer. Transducers utilize piezoelectric or magnetostrictive effects to convert high-frequency electrical signals into mechanical vibrations. The amplitude rod amplifies the small amplitude mechanical vibration generated by the transducer and then transmits it to the ultrasonic probe (also known as the ultrasonic mold). The ultrasonic probe is inserted into the liquid to be processed, and its high-frequency vibration causes tiny bubbles in the liquid to form and grow in the negative pressure zone of the sound wave, and quickly close in the positive pressure zone (i.e. cavitation effect). The enormous energy generated by the cavitation effect is instantly released, forming strong shock waves and microjets, which exert strong shear, impact, and fragmentation effects on particles, droplets, etc. in the liquid, reducing particle size and achieving homogenization; At the same time, mechanical effects can also stir and disperse substances in liquids, further promoting the homogenization process; The heat generated during this process (thermal effect) is relatively small, but in some cases it can also have a certain impact on the temperature of the liquid.

Product Introduction

Ultrasonic homogenizer is a device that utilizes ultrasonic cavitation, mechanical and thermal effects to work. Its generator generates high-frequency electrical signals, which are converted into mechanical vibrations by transducers, amplified by amplitude rods, and applied to liquids through ultrasonic probes. It can crush, disperse, and emulsify liquid particles, achieving homogenization and refinement.

The product features significant homogenization effects up to the nanometer level, mild processing, minimal damage to bioactive substances, flexible operation, and small equipment footprint. It is widely used in biological pharmacy, food industry, chemical industry, cosmetics and other fields, such as cell crushing, preparation of lotion, production of nanomaterials, etc. However, it has a small processing capacity, generates heat during operation, affects thermosensitive substances, and incurs high equipment and maintenance costs.

application area

Biopharmaceuticals: used for cell lysis, releasing bioactive substances such as proteins, enzymes, etc. inside cells; Preparation of drug carriers such as liposomes and nanoparticles to achieve targeted drug delivery; Homogenize biological products such as vaccines to improve their stability and effectiveness.

O Food industry: produce emulsified food, such as mayonnaise, cream, chocolate sauce, etc., to make lotion more stable and delicate; Homogenize fruit juice, jam, etc. to improve taste and stability; Extract effective ingredients from food, such as plant essential oils, natural pigments, etc.

O Chemical industry: prepare nano materials, such as nano particles, nano lotion, etc., and control the particle size and distribution of materials; Disperse coatings, inks, etc. to improve product quality and performance; In the petrochemical industry, it is used for reducing viscosity and breaking emulsions of crude oil.

O Cosmetics industry: prepare lotion, face cream, essence and other cosmetics to make the product texture more uniform and delicate, and improve its stability and absorption; Dispersing and emulsifying cosmetic ingredients to ensure product quality and efficacy

Mold customization

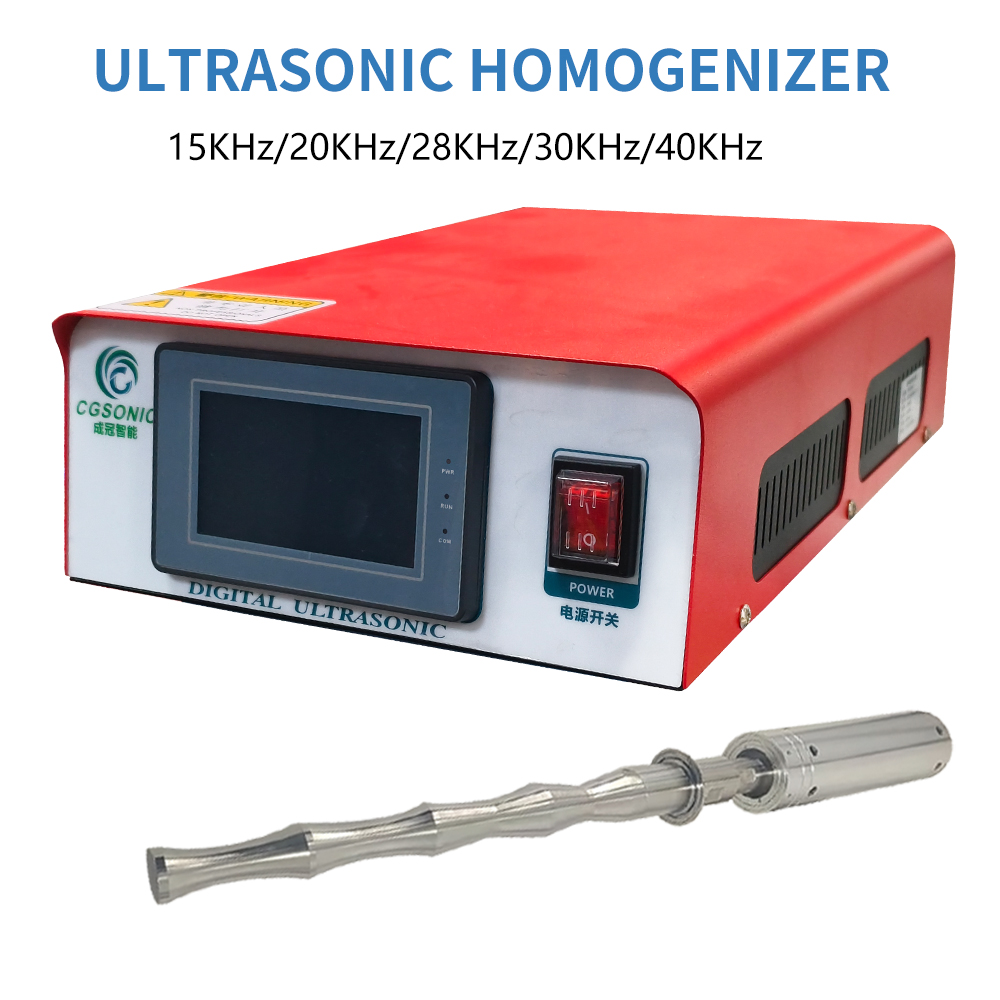

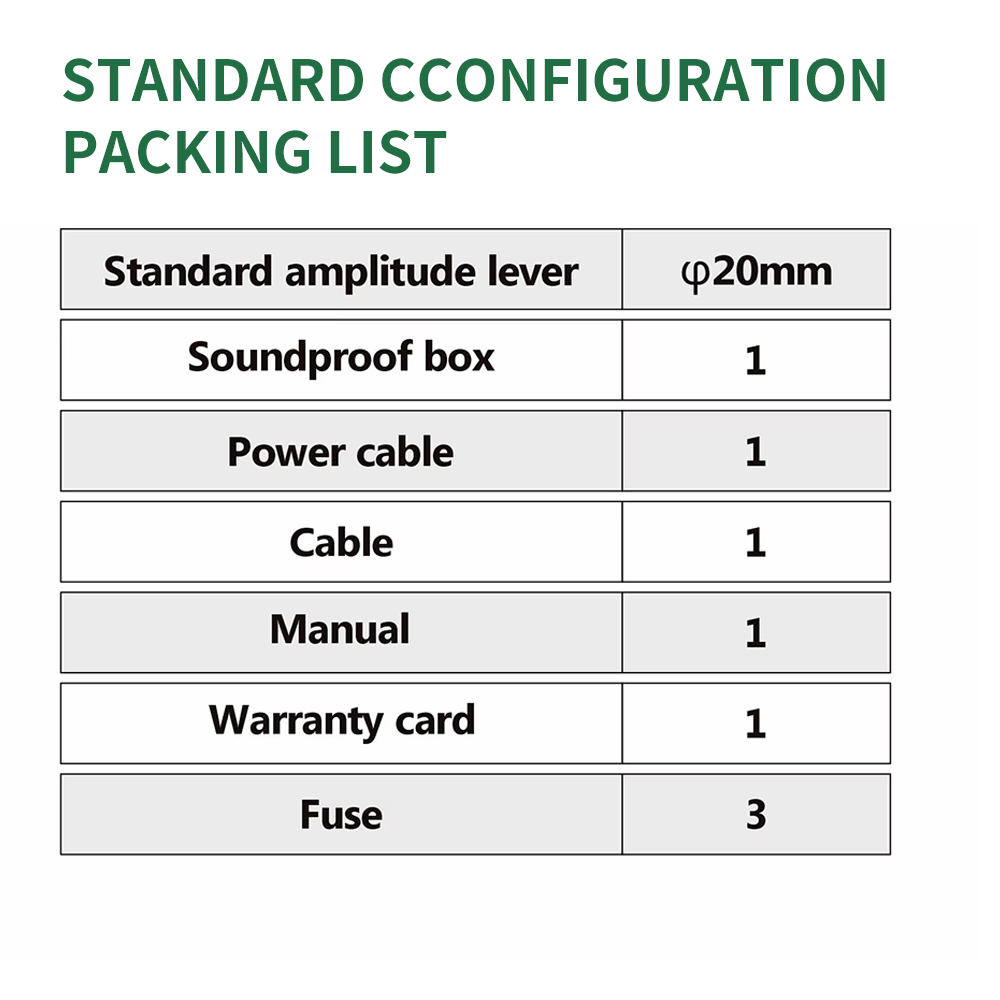

Operating Frequency |

15KHz/ 20KHz/ 28KHz/ 30KHz/ 40KHz |

Output Power |

/ |

Input Voltage |

/ |

Amplitude Adjustment |

/ |

Weld Time |

/ |

Machine Size |

22*36*11cm |

Machine Weight |

|

Connect To Air Pressure |

/ |

Machine maintenance and upkeep

Ultrasonic generator: Regularly check the circuit connection of the generator to ensure good contact, no looseness, aging, or damage. Keep the working environment of the generator dry and ventilated, avoid humid and high-temperature environments, regularly clean the internal dust to prevent dust accumulation from affecting heat dissipation and performance.

Transducers and amplitude rods: Check if the connection between the transducers and amplitude rods is secure, and if there are any cracks, wear, or other abnormalities. Avoid external impact and replace it promptly if any problems are found. Regularly clean its surface to prevent dirt from affecting the transmission of ultrasonic energy.

Ultrasonic probe: After each use, promptly clean the residual materials on the probe to avoid drying and affecting the next work. Regularly check the wear of the probe and replace it if it is severely worn to ensure homogeneity.

Control system: Check whether the buttons, display screens, etc. on the control panel are working properly. If there are any faults, repair or replace them in a timely manner. Regularly backup system parameters to prevent data loss.

Whole machine performance testing: Regularly conduct performance testing on the homogenizer, such as ultrasonic output intensity, frequency stability, homogenization effect, etc., to promptly identify and solve potential problems and ensure stable operation of the equipment.