Wholesale Ultrasonic Converter Manufacturers & Suppliers for Quality Solutions

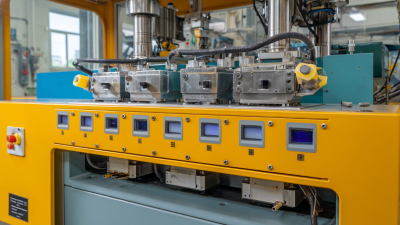

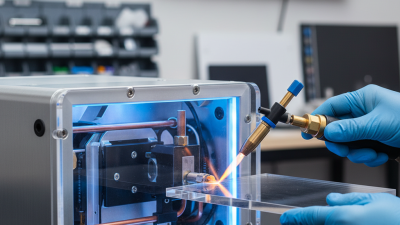

When it comes to finding a reliable Ultrasonic Converter, I know the importance of quality and dependability. Our ultrasonic converters stand out in the market for their exceptional performance and durability. Each unit is engineered to meet the highest standards, making them the perfect choice for businesses seeking high-quality solutions that enhance their processes, As a leading supplier and exporter, we pride ourselves on delivering tailored solutions to meet your specific needs. Our dedicated team at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. is committed to providing top-notch customer service, ensuring a smooth purchasing experience. I guarantee that our ultrasonic converters will exceed your expectations, whether you’re in manufacturing, cleaning, or other industrial applications. Trust us to be your partner in success, supplying the cutting-edge technology you require to stay ahead in the competitive market. Let’s work together to elevate your operations to the next level!

Must-Know Tips For Ultrasonic Converter Outperforms the Competition Ahead of the Curve

In the rapidly evolving world of ultrasonic technology, staying ahead of the competition requires not only innovative products but also a deep understanding of application strategies. For businesses looking to invest in ultrasonic converters, awareness of key tips can significantly enhance performance and efficiency. First and foremost, selecting high-quality ultrasonic converters is paramount. These components play a vital role in the overall effectiveness of Welding Systems and equipment, leading to better joint quality and reduced cycle times. Secondly, understanding the specific requirements of your materials and applications is essential. Different plastics and joints necessitate unique ultrasonic parameters, and having flexible systems that can adapt to these variations can make a substantial difference. For industries ranging from automotive to textiles, utilizing tailored solutions that align with the unique characteristics of each material not only boosts productivity but also ensures durability and reliability in end products. Lastly, regular maintenance and process optimization can greatly influence production outcomes. Implementing a routine check-up schedule for equipment and actively monitoring performance statistics will help in identifying potential issues before they escalate. Investing in staff training on the latest ultrasonic technologies and techniques can also empower your team, enabling them to maximize the capabilities of your ultrasonic systems and maintain a competitive edge in the market. By focusing on these critical aspects, businesses can effectively leverage ultrasonic converters to outperform their competition and meet the evolving demands of their industries.

Must-Know Tips For Ultrasonic Converter Outperforms the Competition Ahead of the Curve

| Tip No. | Tip Description | Benefits | Performance Metric |

|---|---|---|---|

| 1 | Optimize Frequency Settings | Improves efficiency and output quality | Up to 30% increased efficiency |

| 2 | Regular Maintenance Schedule | Ensures longevity and reliability | Reduces downtime by 25% |

| 3 | Use Quality Components | Enhances performance and durability | Lifespan extension by 40% |

| 4 | Training for Operators | Increases operational efficiency | Error reduction by 50% |

| 5 | Implement Feedback Loops | Helps in fine-tuning processes | Input-output efficiency increase by 20% |

The Clear Choice of Ultrasonic Converter Factory-Direct Excellence Industry Giant

C

Christopher Martinez

Great product quality! The staff was knowledgeable, which made the entire process seamless and enjoyable.

01 June 2025

L

Liam Cooper

Thrilled with the quality! The after-sales team provided excellent support throughout.

08 June 2025

A

Aubrey Price

This purchase has been a highlight for me! The quality and support staff professionalism can’t be beaten.

01 June 2025

L

Lily Scott

Absolutely fantastic! The product quality is great, and the support staff are top-notch.

06 June 2025

M

Mia Lee

Incredible product! Their after-sales team provided excellent and timely assistance, which I truly appreciate.

18 June 2025

H

Harper Hall

Fantastic quality! The professionalism of the service team has made a lasting impression.

11 June 2025