Custom Ultrasonic Cutting and Welding Integration by Leading Exporters

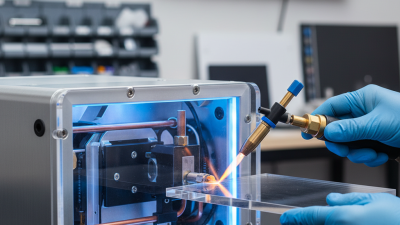

When it comes to Ultrasonic Cutting And Welding Integration, I know the importance of precision and efficiency in manufacturing processes. Our solutions at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. are CE Certified, ensuring top quality and reliability for all your business needs. As a trusted supplier and exporter, we specialize in innovative ultrasonic technology that enhances product quality while reducing operational costs, I believe that integrating ultrasonic cutting and welding can significantly improve your production line, allowing for cleaner cuts and stronger welds without the added hassle of traditional methods. Whether you're in packaging, textiles, or automotive industries, our equipment is designed to meet your unique requirements, Partnering with us means you’re choosing advanced technology backed by years of expertise and customer support. Let's elevate your operations together with our state-of-the-art solutions!

How-To Guide Ultrasonic Cutting And Welding Integration Stands Out Your Trusted OEM Partner

When it comes to advanced manufacturing technologies, ultrasonic cutting and welding are at the forefront of innovation, and partnering with a trusted OEM like Chengguan can help you stand out in a competitive market. With over 20 years of expertise in ultrasonic plastic welding, Chengguan excels in providing a wide range of equipment tailored to meet the specific needs of various industries. Our ultrasonic cutting equipment not only offers precision and efficiency but also enhances productivity while reducing waste. As a global supplier, we understand the diverse requirements of our clients, and our ultrasonic systems are specifically designed to integrate seamlessly into your existing production lines. Whether you need ultraSonic Welding systems for intricate assemblies or ultrasonic extractors and homogenizers for precise material processing, Chengguan’s commitment to quality ensures that you get reliable and innovative solutions. In an era where precision and efficiency dictate success, integrating our ultrasonic technologies can elevate your manufacturing process to new heights. Trust Chengguan as your OEM partner to provide you with the cutting-edge ultrasonic equipment necessary to foster growth and maintain your competitive edge. Let us help you redefine what’s possible in your industry!

How-To Guide: Ultrasonic Cutting And Welding Integration Stands Out Your Trusted OEM Partner

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Ultrasonic Technology | Uses high-frequency sound waves for cutting and welding | Improved precision and reduced material wastage | Automotive, textiles, packaging |

| Energy Efficiency | Requires less energy compared to traditional methods | Lower operational costs | Manufacturing, assembly lines |

| Quality Control | Ensures consistent results and high-quality finishes | Enhanced product reliability | Electronics, sports equipment |

| Versatility | Suitable for various materials | Wide range of application possibilities | Medical devices, aerospace |

| Customized Solutions | Tailored systems for specific production needs | Optimized workflows and efficiency | Packaging, industrial applications |

How To Compare Ultrasonic Cutting And Welding Integration Stands Out Supplies the World’s Top Brands

D

Daniel Martinez

Unmatched quality and stellar after-sales care. The representatives were well-informed and eager to help!

01 July 2025

T

Thomas Young

High-quality product! The service team was not only knowledgeable but also incredibly patient.

18 June 2025

R

Ryan King

Impressive durability! The after-sales service team provided insightful advice that was invaluable.

22 May 2025

S

Sophie Gonzalez

I can’t express how pleased I am! The quality and after-sales support were both exemplary.

21 May 2025

G

Gabriel Foster

Simply put, great quality! The after-sales service was attentive and professional.

14 June 2025

C

Chase Foster

This product truly stands out! And the professionalism of the support staff made the experience better.

20 June 2025