Ultrasonic Fabric Welding Machine OEM Supplier & Manufacturer Solutions

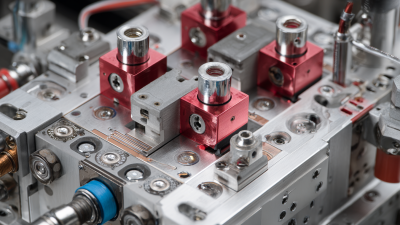

When it comes to precision and efficiency in fabric welding, our Ultrasonic Fabric Welding Machine stands out in the market. As a buyer, you want the best quality, and that's exactly what we offer. Our machines are designed to meet the high standards that modern manufacturers demand, ensuring durability and reliability in every application, I’ve seen firsthand how our Ultrasonic Fabric Welding Machines enhance production lines, saving time and costs without compromising on quality. The technology provides strong bonds without the need for additional adhesives, which is a game-changer, We pride ourselves on being a trusted supplier in the industry, so you can count on us for superior manufacturing standards and unparalleled support. Partner with Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. and elevate your fabric welding processes with our high-quality solutions tailored for your needs. Let's pave the way to innovative manufacturing together!

Practical Methods To Ultrasonic Fabric Welding Machine Leads the Global Market Where Service Meets Innovation

In today’s competitive landscape, industries are constantly seeking innovative solutions to enhance productivity and maintain quality. For over 20 years, Chengguan has been at the forefront of ultrasonic Plastic Welding technology, delivering superior systems that meet the diverse needs of global markets. Our commitment to innovation ensures that our ultrasonic welding machines not only perform exceptionally but also adapt to the evolving demands of various sectors, ranging from automotive to textiles. Chengguan’s ultrasonic welding solutions are designed with versatility and efficiency in mind. Our state-of-the-art equipment, including ultrasonic lace and cutting machines, stands out by offering precise and reliable performance, minimizing material waste while maximizing output. By prioritizing customer service and support, we ensure that our partners can leverage our technology to improve their operational processes, ultimately driving their business growth and enhancing product quality. As we look to the future, Chengguan remains dedicated to leading the market through continuous innovation and exceptional service. By choosing our ultrasonic systems, global buyers are not merely investing in equipment; they are embarking on a partnership that fosters industrial excellence and sustainable development. Let’s take your operations to new heights together.

Practical Methods To Ultrasonic Fabric Welding Machine Leads the Global Market Where Service Meets Innovation

| Dimension | Value | Description |

|---|---|---|

| Market Size (2023) | $450 Million | Estimated global market size for ultrasonic fabric welding machines. |

| Growth Rate (CAGR) | 7.5% | Projected annual growth rate from 2023 to 2028. |

| Main Application Areas | Textiles, Automotive, Medical | Industries where ultrasonic fabric welding is commonly used. |

| Key Benefits | Speed, Precision, Durability | Primary advantages of using ultrasonic welding technology. |

| Major Regions | North America, Europe, Asia-Pacific | Regions leading the market share for these machines. |

| Challenges | High Initial Costs | Main challenge faced by small and medium enterprises. |

| Emerging Trends | Automation & Smart Technology | Increasing adoption of automation in welding processes. |

Top 5 Ultrasonic Fabric Welding Machine in 2025 Industry Giant

O

Olivia Taylor

This purchase was worth every penny! The after-sales service team demonstrated professionalism and quick problem-solving skills.

15 June 2025

S

Samuel Green

Definitely worth it! The expertise and professionalism of the support staff impressed me.

17 June 2025

S

Scarlett Wood

High-quality item! The customer service team was courteous and knowledgeable.

16 June 2025

R

Riley Rogers

I am very pleased! The product is stable and the after-sales service was professional and insightful.

19 May 2025

E

Evelyn Martin

Amazing quality product! The after-sales service has been just as exceptional, demonstrating their expertise.

05 July 2025

M

Madelyn Baker

One of my best purchases! The quality is impressive, and the service team is incredibly professional.

16 June 2025