- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

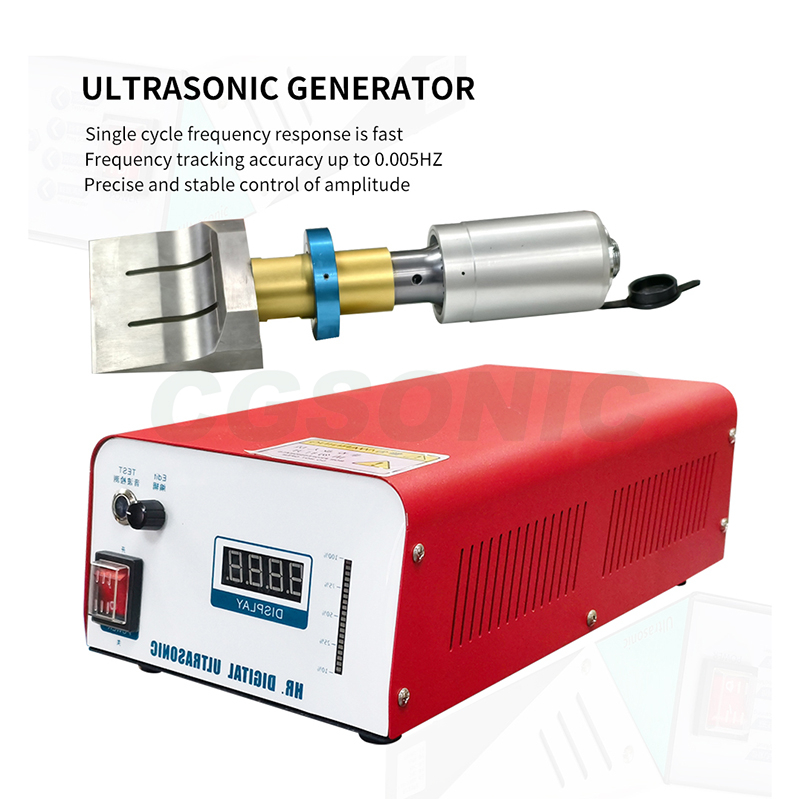

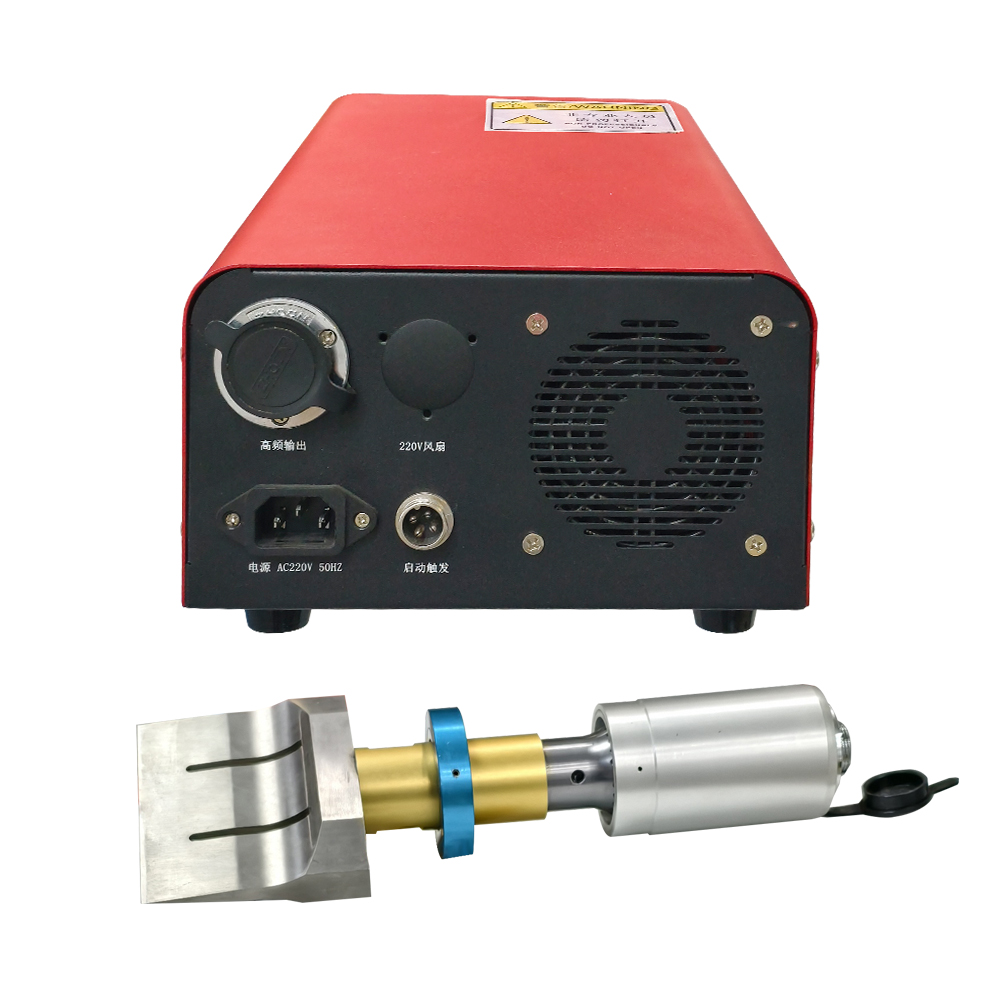

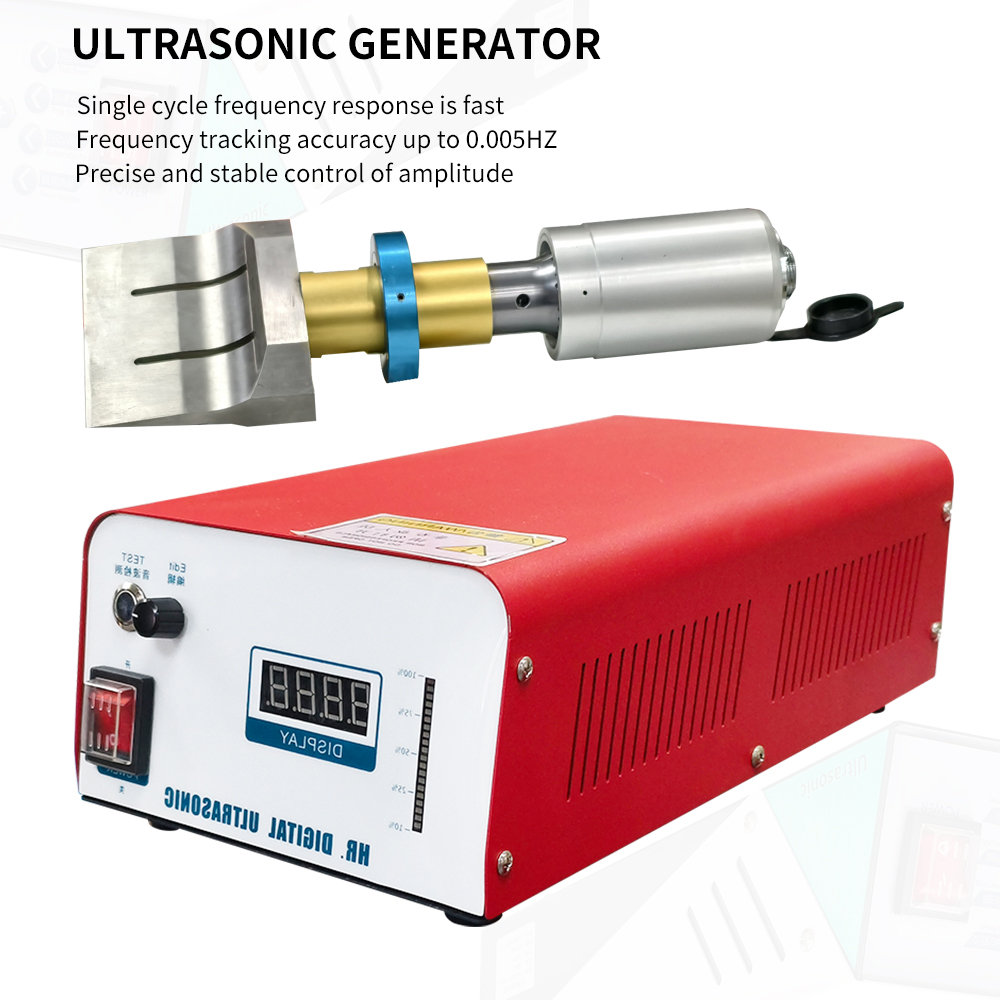

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

Ultrasonic food cutting system

Working Principle

The ultrasonic generator generates high-frequency electrical signals, which are received by the transducer and converted into ultrasonic frequency mechanical vibrations using the piezoelectric effect. The amplitude lever further amplifies the amplitude, causing the cutting tool to generate tens of thousands of high-frequency vibrations per second. When cutting food, this high-frequency vibration reduces the friction between the cutting tool and the food, and the local high temperature generated can instantly melt a small part of the food, making the cutting process smoother.

Product Introduction

Ultrasonic food cutting system is a device that uses ultrasonic technology to achieve efficient and precise cutting of food. It greatly improves the cutting effect by converting electrical energy into high-frequency mechanical vibration. Can be connected to an automation system to achieve automated cutting

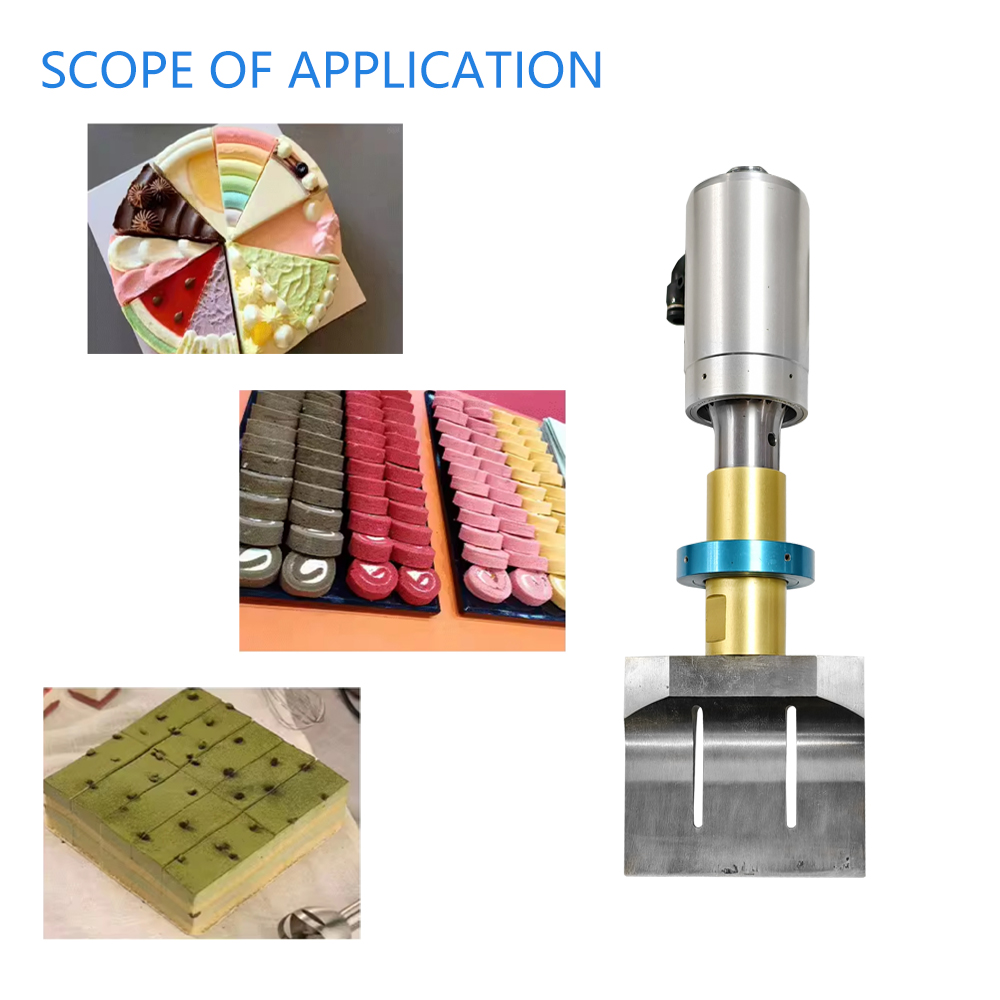

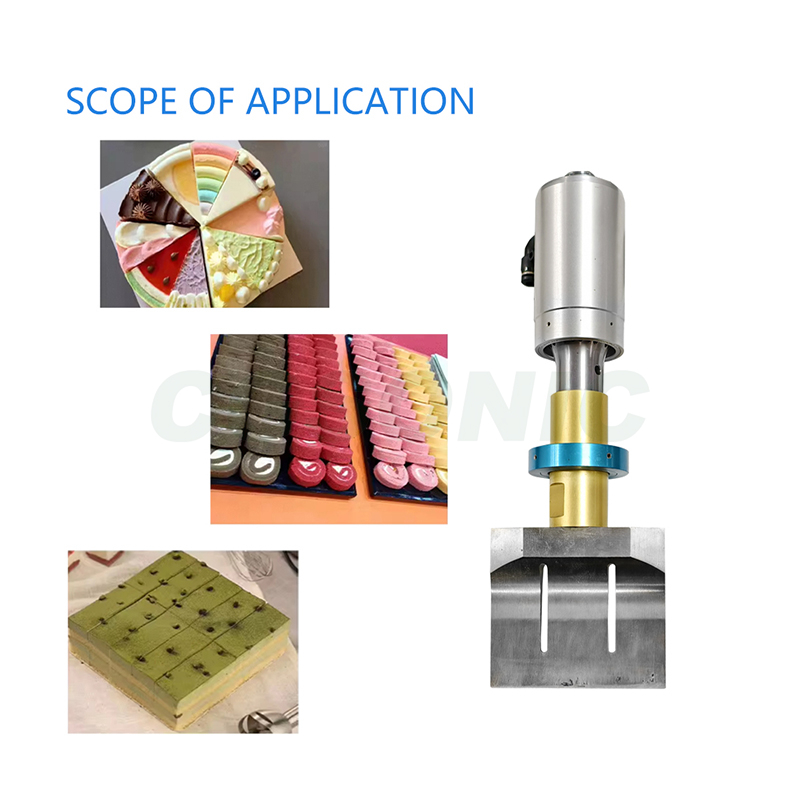

application area

Baking industry: Cut bread, cakes, pastries, etc. to ensure a smooth cut without damaging the appearance of the product.

Candy and chocolate industry: Cut chocolate, candies, etc. to avoid product breakage and deformation.

Meat processing: segmenting meat to improve cutting efficiency and quality, and reduce meat juice loss.

Frozen food processing: When cutting frozen food, there is no need to thaw it in advance, reducing the loss of food quality. Cosmetics industry: Prepare lotion, face cream, essence and other cosmetics to make the product texture more uniform and delicate, and improve its stability and absorption; Dispersing and emulsifying cosmetic ingredients to ensure product quality and efficacy

Mold customization

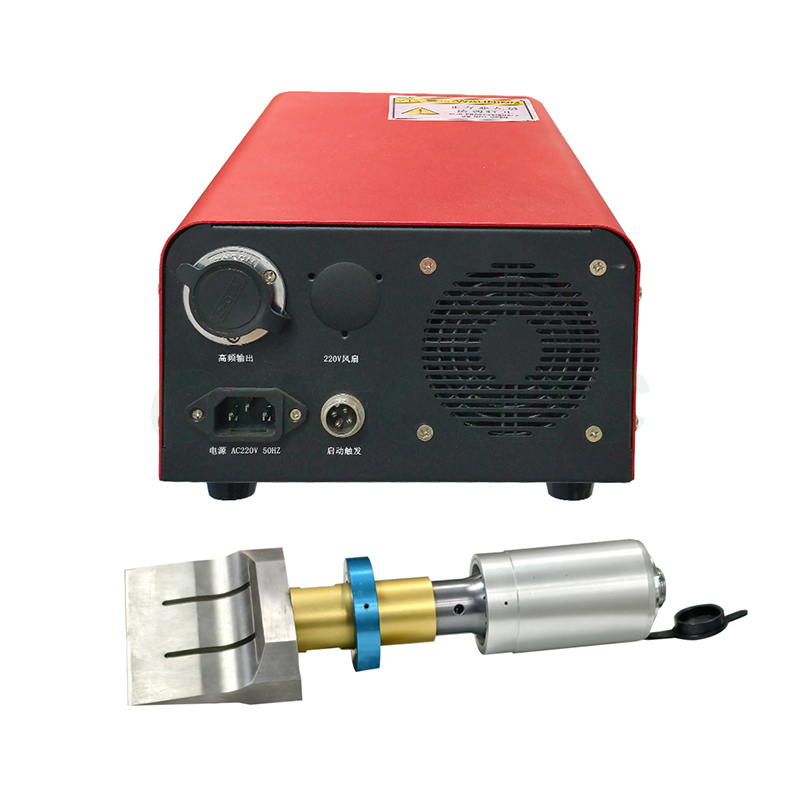

Operating Frequency |

15KHz/20KHz/28KHz/30KHz/40KHz |

Output Power |

/ |

Input Voltage |

/ |

Amplitude Adjustment |

/ |

Weld Time |

/ |

Machine Size |

|

Machine Weight |

/ |

Connect To Air Pressure |

/ |

Machine maintenance and upkeep

Cutting tool: After each use, carefully clean the blade with a soft cloth and specialized cleaning agent to remove food residue and prevent corrosion. Regularly check the wear of cutting tools. If the blade is no longer sharp or has gaps, replace it in a timely manner to ensure cutting accuracy.

Ultrasonic system: Keep the working environment of the ultrasonic generator dry and ventilated, regularly clean the internal dust, and prevent overheating. Check the generator parameters to ensure stable output power and frequency. Check if the connection between the transducer and the amplitude rod is secure and if there is any damage. If there are any issues, promptly address them.

Mechanical components: Regularly add lubricating oil to transmission components such as motors, chains, and guide rails to reduce wear and ensure smooth operation. Check the screws of each connecting part and tighten any loose components in a timely manner.

Electrical system: Check whether the circuit is damaged or aged to avoid short circuits and leakage. Regularly clean the dust of electrical components to ensure good heat dissipation. Test whether the control buttons and display screen are working properly, and repair or replace them promptly if there are any faults.

Whole machine inspection: Regularly conduct comprehensive performance tests on the equipment, such as cutting speed, cutting effect, ultrasonic output intensity, etc., to promptly identify and solve potential problems and ensure stable operation of the equipment.