- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

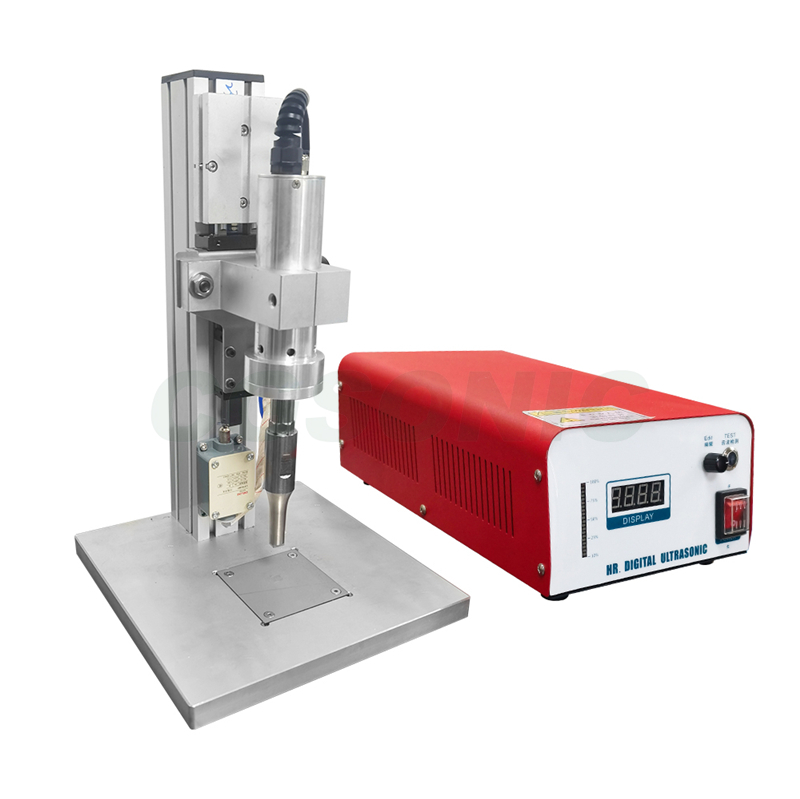

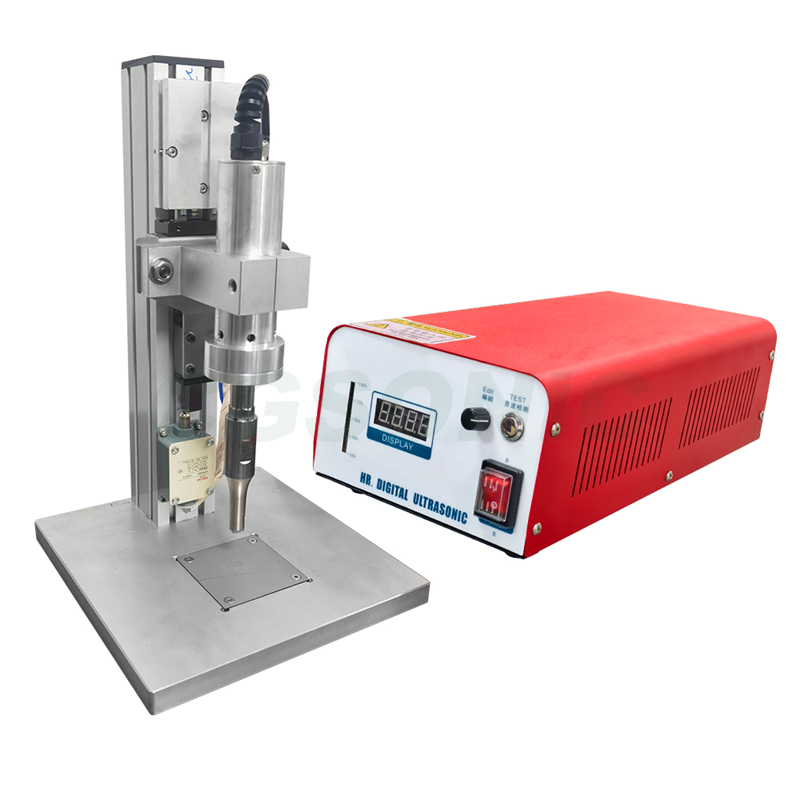

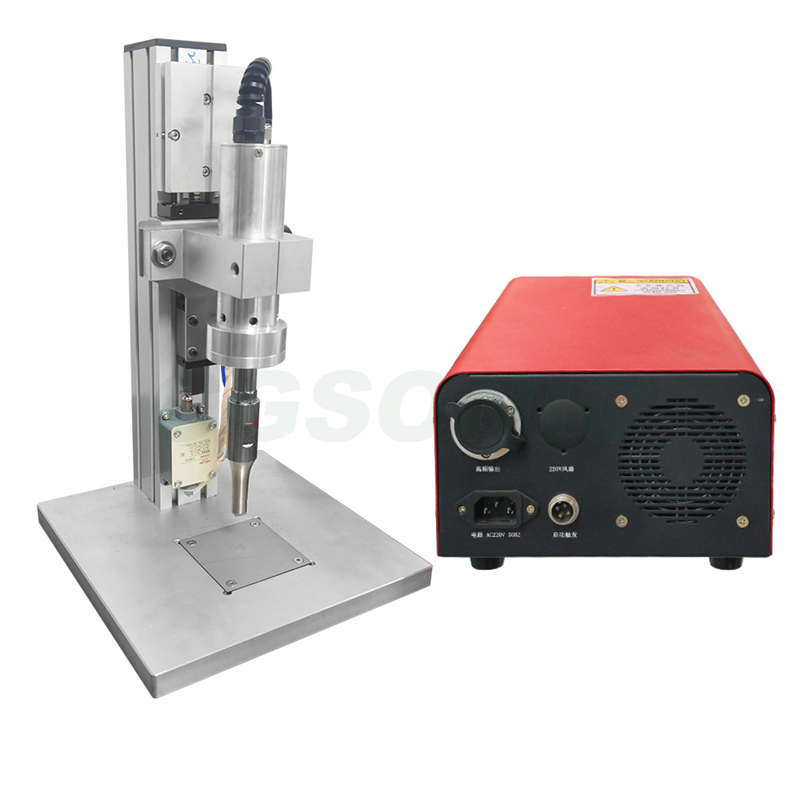

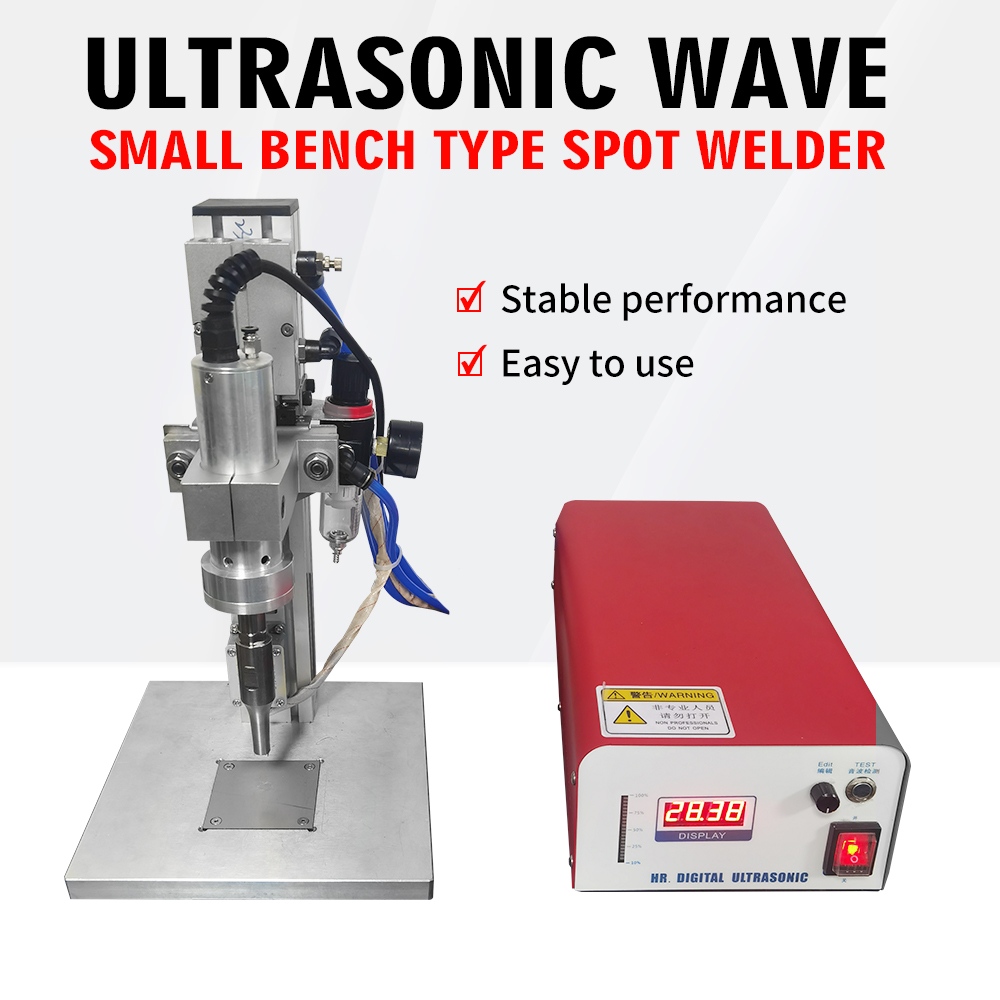

Ultrasonic Geng tabletop small spot welder

short description part

High welding quality : The solder joints are firm and beautiful, and are not prone to problems such as cold solder joints and desoldering. This can ensure product quality and stability and reduce the defective rate.

Easy to operate : The operation interface is simple and easy to understand, no professional skills are required, and novices can start operating after simple training.

Wide range of applications : It can weld a variety of materials, such as plastics, metal sheets (aluminum foil, copper foil, etc.), non-woven fabrics, etc., and is suitable for welding needs in different industries.

working principles

The ultrasonic generator generates a high-frequency electrical signal, which is converted into tens of thousands of ultrasonic frequency mechanical vibrations per second by the transducer. The amplitude is further amplified by the horn and then transmitted to the welding head. When the welding head contacts the material to be welded, the high-frequency vibration causes the material molecules to rub at high speed to generate heat, instantly melting the contact surface. Under the action of pressure, the materials fuse together and form a solid weld after cooling.

Product Introduction

Desktop ultrasonic small spot welding machine uses ultrasonic high-frequency vibration to achieve material welding. It consists of an ultrasonic generator, a transducer, a horn, a welding head and a control system. When working, the generator generates a high-frequency electrical signal, which is amplified by the transducer and the horn and transmitted to the welding head, so that the contact surface of the material is fused due to frictional heat.

This device is small and portable, suitable for small space operations; highly efficient and energy-saving, fast welding speed, low energy consumption; high welding quality, firm and beautiful welding points; easy to operate, easy for novices to use. It is widely used in electronics, jewelry, clothing, medical, handicraft production and other industries, and can weld plastics, metal sheets, non-woven fabrics and other materials.

application areas

Electronics industry: welding electronic components, such as chip pins on circuit boards, wire connectors, micro sensors, etc., requires high precision and quality of solder joints, and desktop ultrasonic small spot welders can meet the needs.

Jewelry processing: used for welding parts of gold, silver, jewelry, diamonds and other accessories, such as chain connections, gemstone inlays, etc., which can achieve fine welding without damaging the surface of the material.

Clothing and textile industry: welding clothing accessories, such as zipper top and bottom stops, buttons, Velcro, etc.; welding of non-woven products, such as mask ear straps, protective clothing, eco-friendly bags, etc., can improve production efficiency and product quality.

Medical device manufacturing: Welding medical plastic parts, such as syringes, infusion tubes, medicine bottles, etc., to ensure that the products are sterile, sealed, and meet medical standards.

Crafts making: In the making of crafts made of wood, plastic, metal and other materials, it is used to connect parts to achieve creative design and meet personalized needs.

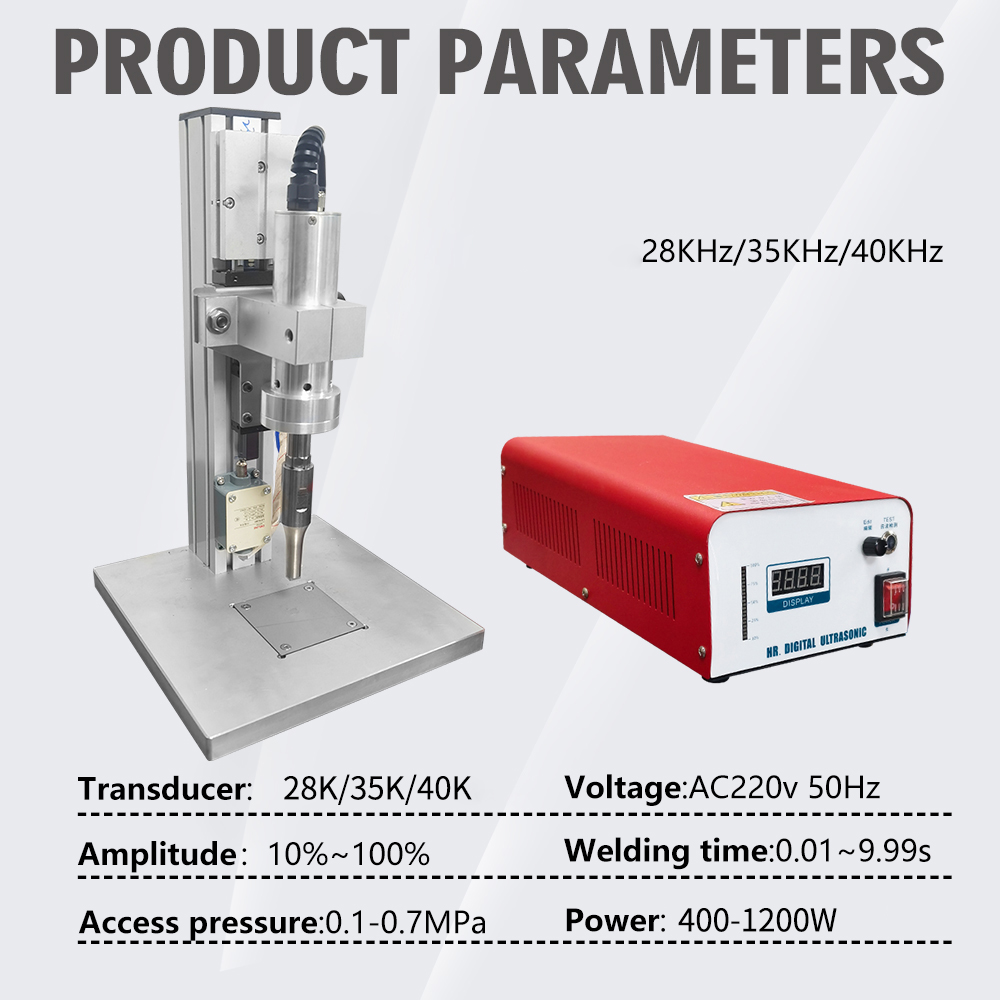

Product Parameters

Operating frequency |

15KHz/20KHz/28KHz/30KHz/40KHz |

Output Power |

/ |

Input voltage |

AC220v 50Hz |

Amplitude adjustment |

1%~100% |

Welding time |

0.01~9.99s |

Machine size |

284*390*485mm |

Machine weight |

2.5KG |

Access air pressure |

0.1~0.7MPa |

Machine maintenance

Appearance cleaning: Wipe the body regularly with a clean soft cloth to remove dust and stains, and prevent debris from entering the interior and affecting performance.

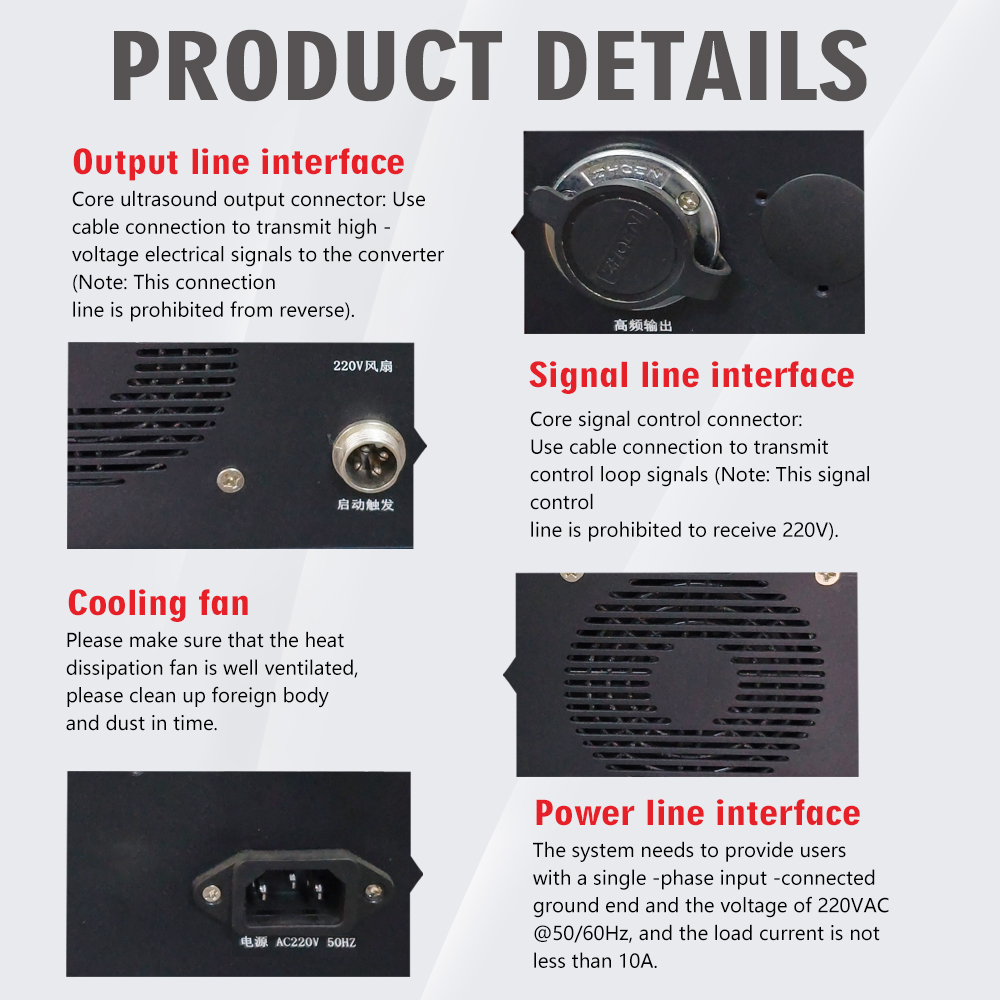

Ultrasonic generator: Check whether the line connection is loose and ensure good ventilation and heat dissipation to prevent malfunction due to overheating.

Transducer and horn: Check for cracks, wear, and whether the connection is firm. If there is any problem, replace or tighten it in time.

Welding head maintenance: clean the surface residue after each use, check the wear regularly, and replace it in time if it is severely worn to ensure the welding effect.

Control system: Regularly check whether the control buttons and display screen are working properly to avoid misoperation and update the system software in time.

Regular inspection: Check the overall performance of the equipment at regular intervals, such as welding strength, frequency stability, etc., to ensure that the equipment is in the best working condition.

After-Sales Service

Our warranty is 1 years, and if you have any other problems about it, we'll provide you online technical support to help you.