- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

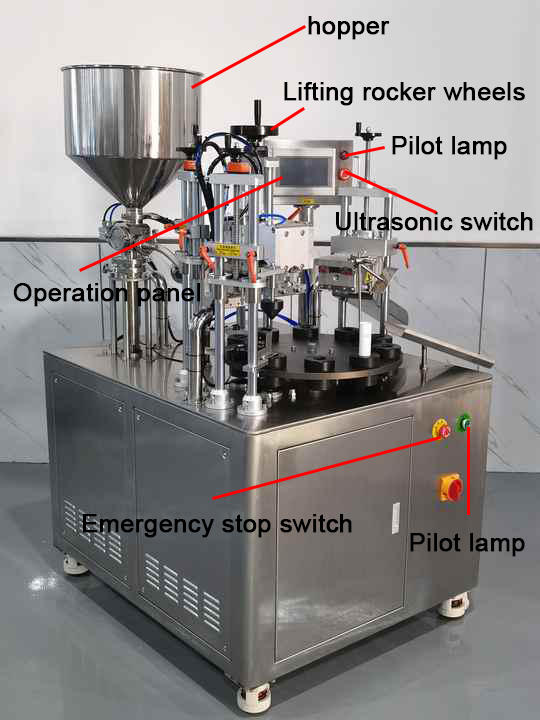

Ultrasonic multi-station turntable automatic filling and sealing machine

short description part

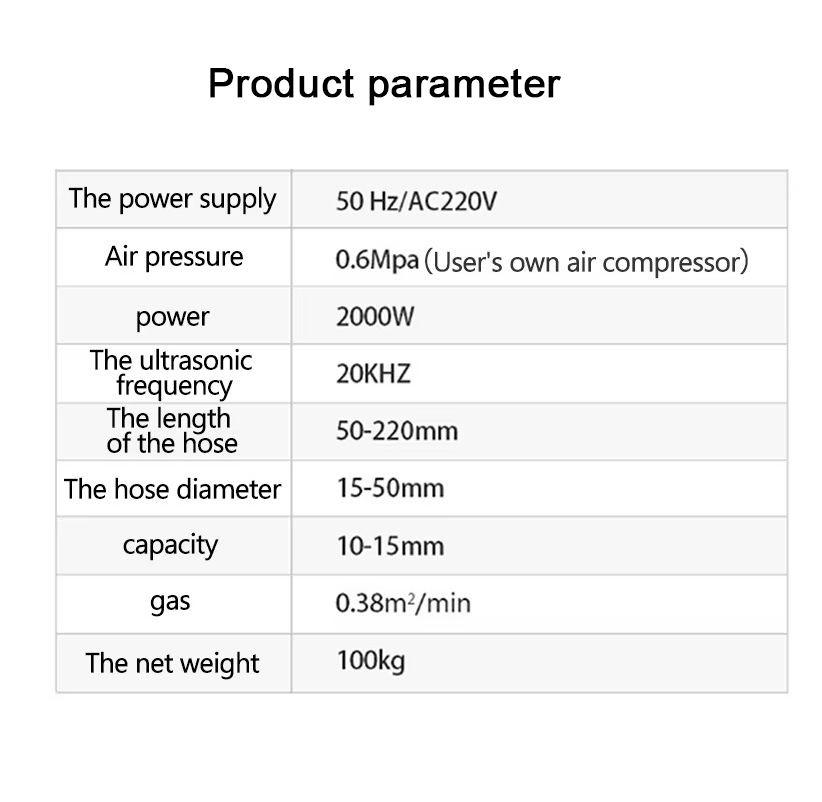

Intelligent flexible control: PLC+touch screen control system can quickly switch between different tube diameters (10-50mm) and sealing parameters, adapting to the needs of multiple industries such as ointments, adhesives, and cosmetics, and compatible with aluminum-plastic/plastic hoses.

Core advantages:

Ultrasonic sealing - non-melting, no debris, suitable for heat-sensitive materials

High-precision filling - servo pump control, error ≤ ± 1%

Modular design - easy to clean and maintain, in line with GMP standards

Working Principle

When the ultrasonic multi-station turntable automatic filling and sealing machine is working, the conveyor belt first delivers the container to each station of the turntable. After positioning, the filling system pours the material from the material cylinder into the container through the metering device according to the preset amount. Then, the ultrasonic generator generates a high-frequency electrical signal, which is converted into mechanical vibration by the transducer, and then amplified by the amplitude rod and transmitted to the welding head, so that the material at the tail of the hose heats up and softens under the action of vibration, fuses under the pressure of the welding head, and completes the sealing after cooling. The turntable moves intermittently, and under the control of PLC, each station works together to realize the automated production of container loading, filling, sealing and finished product unloading.

Product Introduction

1. Container loading: The containers to be filled, such as hoses, are placed on the feed conveyor belt, which transports the containers one by one to the loading station of the turntable. There are multiple equally spaced stations on the turntable, each corresponding to a container.

2. Container positioning: When the container arrives at the turntable station, the positioning device will quickly and accurately fix the container in the predetermined position to ensure the accuracy of subsequent filling and sealing operations. This process is usually achieved through the coordinated work of mechanical clamps, pneumatic devices or photoelectric sensors.

3. Material filling: After the container is positioned, the turntable transports it to the filling station. The material in the material cylinder is kept uniform under the action of the stirring device, and then the material is accurately injected into the container according to the preset filling amount through a metering device such as a metering pump. The metering pump is driven by a motor, and the output of the material is accurately controlled by controlling the speed and stroke of the motor.

4. Ultrasonic tail sealing: The filled container rotates with the turntable to the tail sealing station. At this time, the ultrasonic generator generates a high-frequency electrical signal, which is converted into mechanical vibration, that is, ultrasonic wave, by the ultrasonic transducer. The horn amplifies the ultrasonic vibration and transmits it to the welding head, which contacts the tail of the hose, so that the material at the tail of the hose quickly heats up and softens under the action of ultrasonic waves. At the same time, the welding head applies a certain pressure to make the softened materials fuse with each other and form a firm seal after cooling.

5. Finished product unloading: After the tail is sealed, the finished product rotates with the turntable to the unloading station, and the unloading device removes it from the turntable, places it on the discharge conveyor belt, and transports it to the next process or finished product collection area.

6. Turntable motion control: The turntable adopts intermittent motion mode and is driven by the motor through a reducer, a dividing mechanism, etc. Under the precise control of the PLC (programmable logic controller), the turntable rotates a certain angle each time to accurately transport the container to each station, ensuring that the operation of each station can be carried out in an orderly and precise manner. At the same time, the PLC also communicates with the actuators and sensors of each station, coordinates their actions, and realizes the automation of the entire filling and sealing process.

7. Quality inspection and control: In the production process, multiple inspection points are usually set up, such as checking whether the filling volume meets the standard after the filling station, and checking whether the sealing quality is good after the sealing station. Once unqualified products are detected, the system will automatically remove them or issue an alarm to notify the operator to handle them. In addition, the equipment also has parameter setting and adjustment functions. The operator can conveniently set parameters such as filling volume, sealing time, welding head pressure, etc. through the human-machine interface according to different product specifications and production requirements to ensure that the equipment can adapt to the production needs of various products.

Application Fields

Cosmetics industry: the industry has a wide range of products, such as lotion, face cream, essence in skin care products, lipstick, lip gloss, eye black in cosmetics, etc., which usually use flexible tubes or similar packaging containers. The ultrasonic multi station turntable automatic filling and sealing machine can accurately control the filling volume, ensuring that the filling volume of each product is accurate. At the same time, using ultrasonic sealing technology, the packaging appearance can be flat and sealed well, improving the quality and grade of the product.

Pharmaceutical industry: in the pharmaceutical field, the requirements for the packaging of drugs are extremely strict, whether it is ointment, gel and other external drugs, or some oral liquid drugs, all need accurate filling and reliable sealing. This device can achieve high-speed and high-precision filling and sealing operations in accordance with the requirements of Good Manufacturing Practice (GMP), ensuring accurate dosage and sealed packaging of drugs, preventing external contamination, and ensuring the quality and safety of drugs.

Food industry: In the food industry, some sauces, jams, honey, edible oils and other products are often packaged in hoses or plastic bottles. The ultrasonic multi station turntable automatic filling and sealing machine can meet the strict requirements of hygiene and safety in the food industry. The parts that come into contact with materials are usually made of materials that meet food grade standards and are easy to clean and disinfect. At the same time, the equipment can quickly and accurately complete the filling and sealing process, improve production efficiency, and adapt to the large-scale production needs of the food industry.

Daily necessities industry: Toothpaste, shoe polish, shower gel, shampoo and other products in the daily necessities industry are often packaged in hoses or bottles. This device can be flexibly adjusted and configured according to the characteristics and packaging requirements of different products, achieving diversified filling and sealing functions. For example, for the filling of toothpaste, the extrusion amount of the paste can be precisely controlled to ensure that the net content of each toothpaste tube is consistent; For the filling of liquid products such as shower gel and shampoo, the shape and size of the filling head can be adjusted to achieve fast and leak free filling.

details display

Machine maintenance and upkeep

1. Cleaning operation

Clean the turntable track, filling head, and ultrasonic head with a dust-free cloth

Wipe the parts in contact with the material (such as filling needles) with alcohol (concentration 75%)

Remove residues from the waste collection box

2. Lubrication inspection

Add food grade lubricating grease to the turntable bearings (once a week)

Check if the cylinder rod needs to be supplemented with silicon-based lubricating oil

3. Inspection of key components

Confirm that the cooling fan of the ultrasonic generator is operating normally

Check the sensitivity of each sensor (photoelectric/proximity switch)

4.maintenance, it is necessary to

Cut off the power/gas source

Release residual pressure in the system

Wear anti-static wristband (for electronic component maintenance)

5. Prohibited operations:

Live plug and unplug ultrasonic generator connector

Use metal tools to directly strike the welding head

Superparameter operation (such as continuous 24-hour full load)

After-Sales Service

Our product comes with a one-year warranty service and fully protects your right to use during the warranty period. In addition, if you encounter any problems or technical issues during use, our professional online technical support team will be available to answer your questions at any time and provide efficient and thoughtful solutions.