- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

Ultrasonic nozzle separation machine 15k20k28k30k35k40k vibration nozzle

short description part

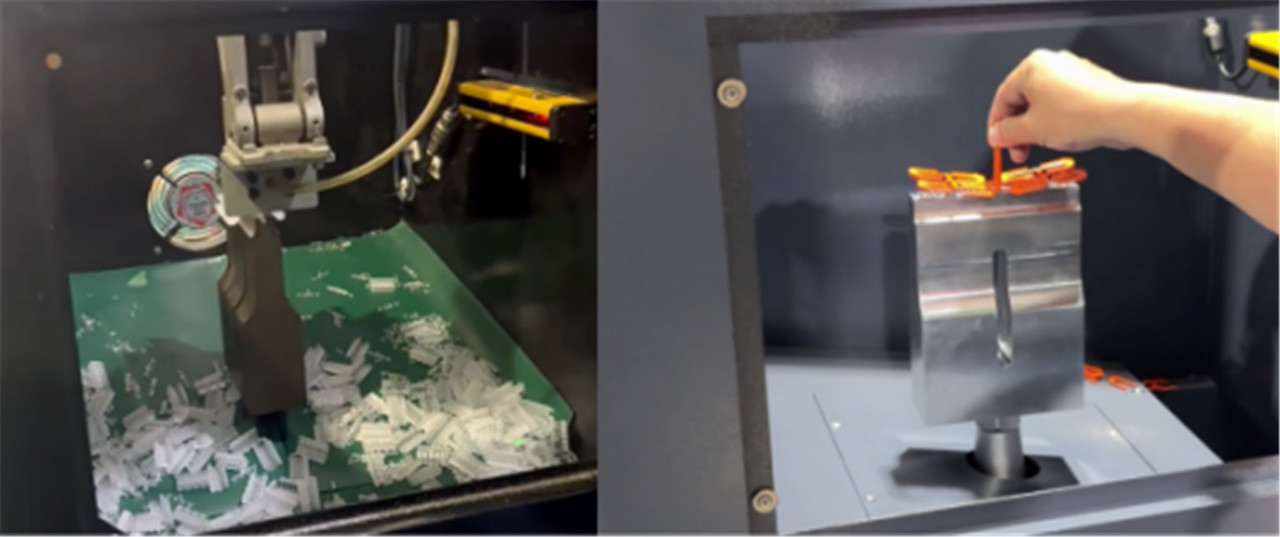

The ultrasonic sprue trimming machine operates on the principle of high-frequency ultrasonic vibrations. The ultrasonic generator produces high-frequency electrical signals, which are converted into mechanical vibrations by the transducer. When plastic parts with sprues (excess material from injection molding) are placed between the welding head and the base, the high-frequency vibrations generate rapid frictional heat at the sprue interface. This melts the plastic, allowing the sprue to be cleanly severed or removed from the main product.

Product Introduction

1. High Efficiency: Compared to manual or mechanical trimming methods, the ultrasonic sprue trimmer significantly boosts productivity, ideal for mass production.

2. Smooth Cutting: Ultrasonic melting ensures neat, burr-free cuts, eliminating the need for post-processing like grinding.

3. High Automation: Compatible with automated feeding and ejection systems, reducing labor costs and manual intervention.

4. Wide Compatibility: Suitable for various thermoplastic products, regardless of complexity, ensuring precise sprue removal.

application areas

1. Injection Molding: Essential for post-processing of plastic toys, tableware, household items, and electronic housings.

2. Automotive Parts: Ensures dimensional accuracy and surface quality for plastic components in the automotive industry.

3. 3C Products: Efficiently trims sprues from phone cases, laptop shells, charger housings, etc., enhancing product quality.

details display

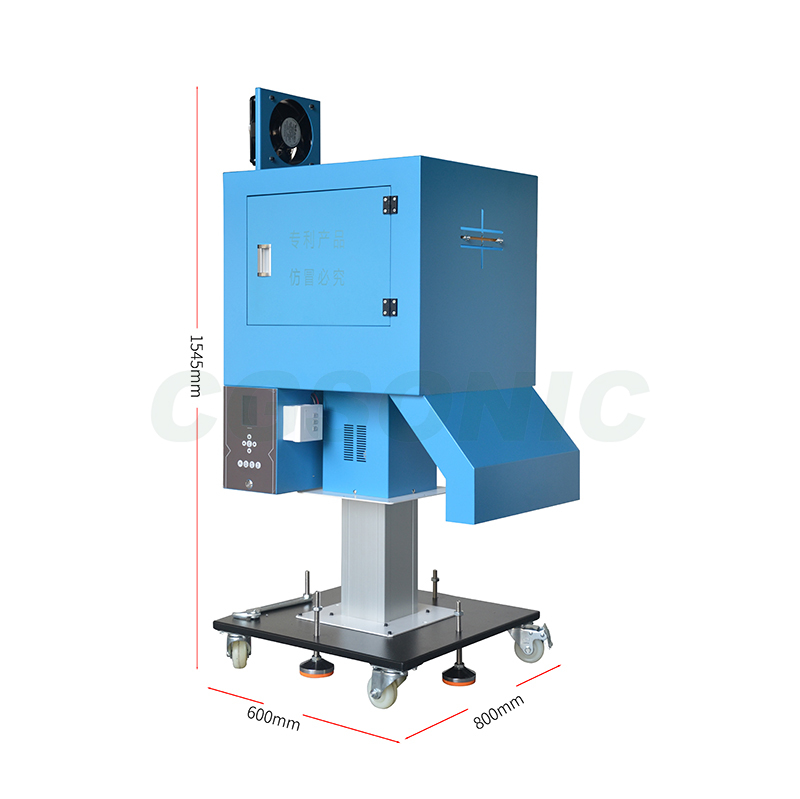

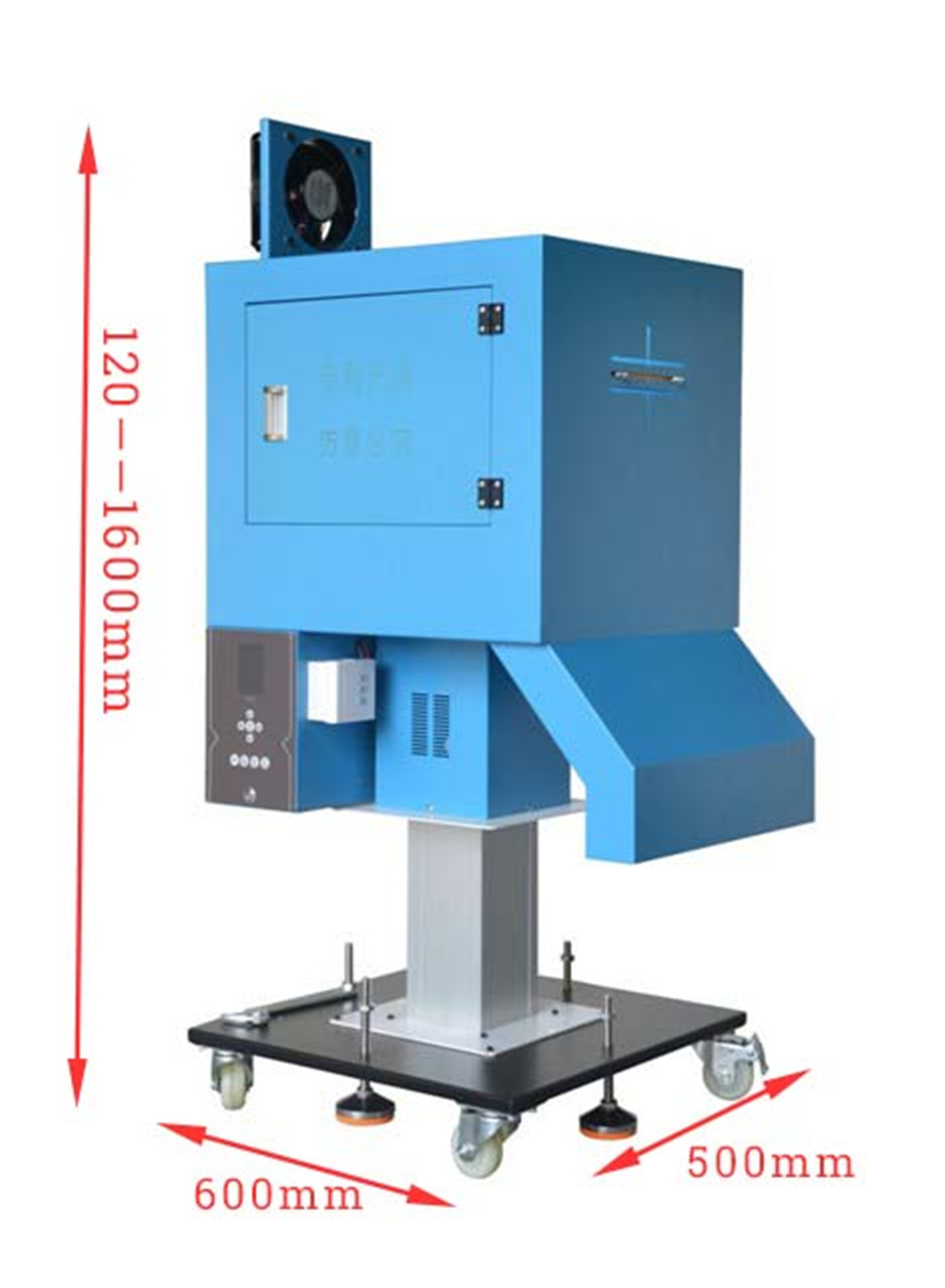

Product Parameters

Parameter |

Specification |

Working Frequency |

15KHz / 20KHz |

Output Power |

1500–3000W |

Input Voltage |

AC220V 50Hz |

Amplitude Adjustment |

1%–100% |

Trimming Time |

0.01–9.99s |

Dimensions |

600×500×1600mm |

Weight |

70KG |

Air Pressure |

0.1–0.7MPa |

Machine maintenance

1. Mechanical: Lubricate lead screws and rails regularly; inspect clamps for secure gripping; tighten loose screws.

2. Ultrasonic System: Keep the generator dry and ventilated; clean dust; check connections and parameters.

3. Electrical: Inspect wiring for damage; clean dust from components; test buttons and displays.

4. Tooling: Clean residue from blades after use; replace worn blades promptly.

5. Performance Checks: Regularly test ultrasonic output, cutting speed, and other metrics to preempt issues.

After-Sales Service

We offer a 1-year warranty and provide online technical support for any inquiries.