Ultrasonic Plastic Welding OEM Solutions from Leading Manufacturers

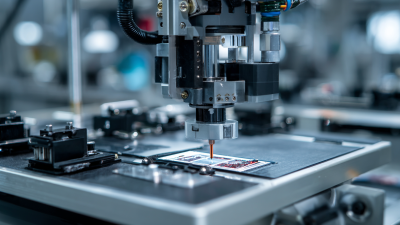

When searching for high-quality ultrasonic plastic welding solutions, you want a reliable manufacturer that understands your needs. At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we specialize in state-of-the-art ultraSonic Welding technology tailored for various applications. Our ultrasonic plastic welding equipment delivers precise and efficient results, ensuring strong and durable welds for your products, We take pride in our commitment to quality, providing customers with durable machines that enhance production efficiency. Our factory is equipped with advanced technology, allowing us to meet diverse industry demands, from automotive to electronics. You’ll find our products not only competitive in price but also superior in performance, Partnering with us means investing in innovation and reliability. We’re here to support your business with exceptional service and customized solutions. Let’s revolutionize your production line with our ultrasonic plastic welding systems, designed specifically to elevate your manufacturing processes. Reach out to learn more about our offerings!

Top Picks For Ultrasonic Plastic Welding Now Trending Service

In the ever-evolving world of manufacturing, ultrasonic plastic welding has emerged as a leading solution for industries seeking efficient and precise joining methods. For over 20 years, Chengguan has been a pioneer in this field, specializing in a diverse range of ultrasonic plastic welding systems and equipment tailored to meet the unique demands of various sectors. From automotive to medical, our ultrasonic welding technology not only ensures robust and reliable joint integrity but also enhances production efficiency, making it a top choice for global buyers. At Chengguan, we offer a comprehensive suite of ultrasonic solutions, including ultrasonic lace and cutting equipment, extractors, and homogenizers. Our commitment to innovation and quality has established us as a trusted partner for businesses looking to optimize their manufacturing processes. As we continue to stay at the forefront of industry trends, our latest ultrasonic welding systems are designed to support advancements in automation and sustainability, aligning with the evolving needs of our customers worldwide. By choosing Chengguan, you are not just selecting a product; you are investing in a partnership that values your success and growth. As we set new benchmarks in ultrasonic technology, we invite global procurement professionals to explore our trending services and discover how our expertise can transform their production lines. Together, let's redefine the future of plastic welding.

Top Picks For Ultrasonic Plastic Welding Now Trending Service

| Service Type | Material Compatibility | Application | Welding Technology | Approx. Cost Range |

|---|---|---|---|---|

| Automotive Parts | Polypropylene, ABS | Bumpers, Trim | Standard Ultrasonic Welding | $500 - $2000 |

| Consumer Electronics | Polycarbonate, PVC | Casing, Connectors | Laser Ultrasonic Welding | $800 - $2500 |

| Medical Devices | Polystyrene, HDPE | Syringes, Housings | Ultrasonic Spot Welding | $1000 - $3000 |

| Packaging | PET, Polypropylene | Containers, Seals | High-Frequency Ultrasonic Welding | $600 - $1800 |

| Electrical Assemblies | Nylon, Polyurethane | Wires, Connectors | Ultrasonic Time-Pressure Welding | $700 - $2200 |

Uncovering Ultrasonic Plastic Welding Sets the Industry Standard More Than a Supplier - A Partner

R

Richard Anderson

The quality of this product exceeded my expectations! The after-sales service was fantastic, and the team was incredibly knowledgeable.

01 June 2025

V

Victoria Bennett

Wonderful quality! The after-sales personnel were educated and genuinely caring.

09 May 2025

D

David Jackson

High-quality item! The after-sales support really went above and beyond.

31 May 2025

M

Mia Lee

Incredible product! Their after-sales team provided excellent and timely assistance, which I truly appreciate.

18 June 2025

H

Harper Hall

Fantastic quality! The professionalism of the service team has made a lasting impression.

11 June 2025

E

Emily Reed

Wonderful item! The customer service was exceptional and made me feel valued.

30 May 2025