- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

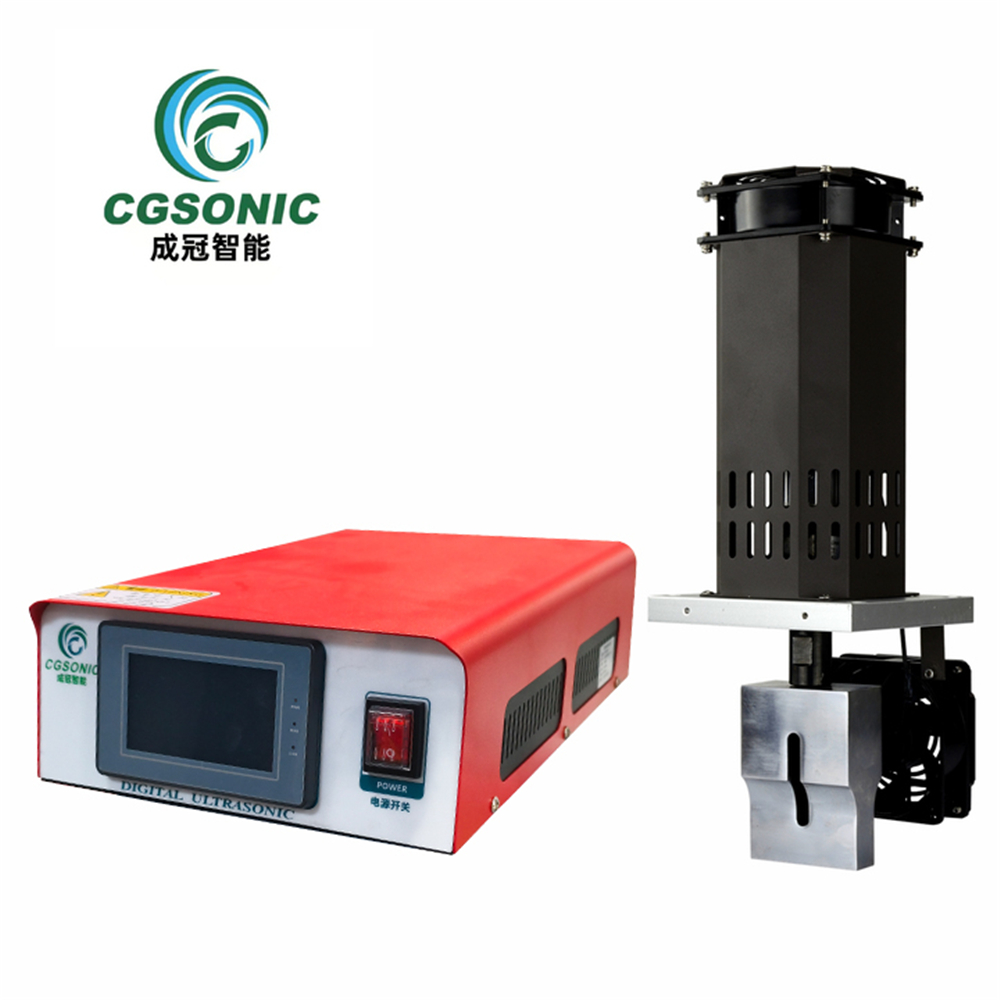

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

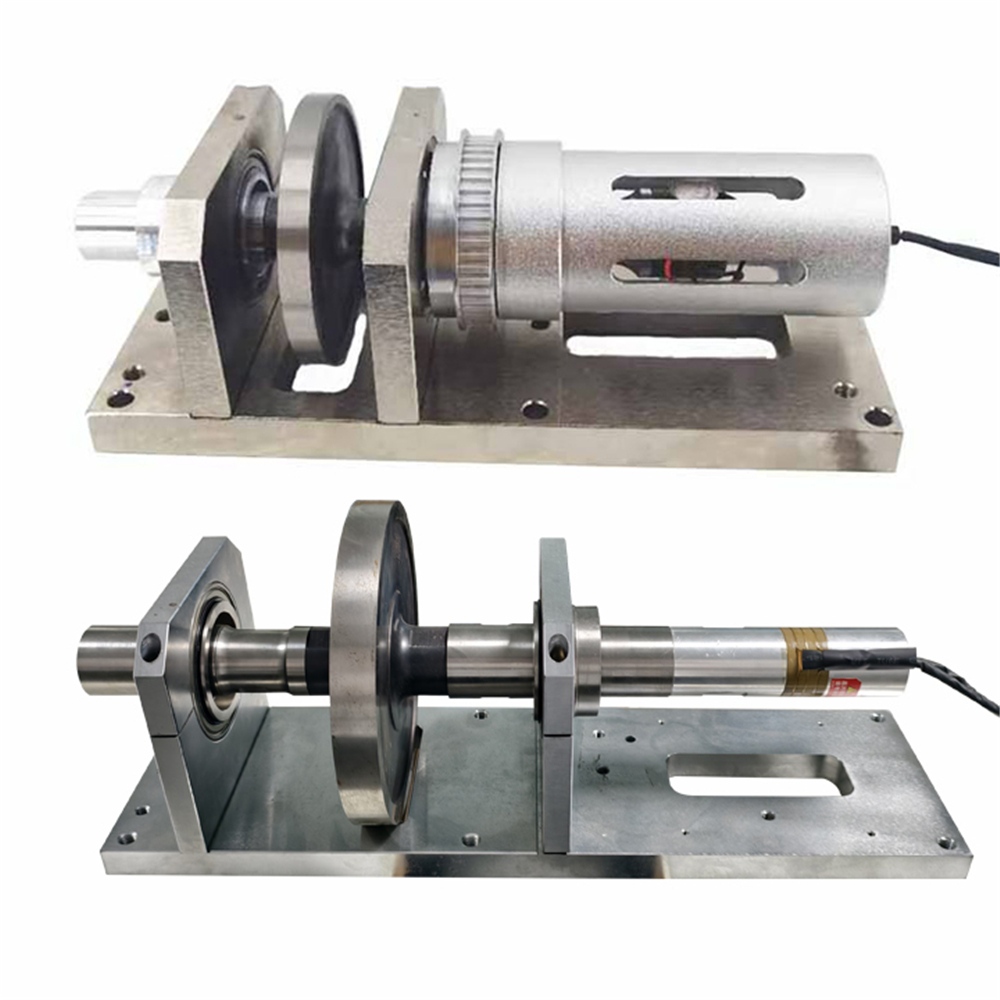

Ultrasonic radial application system

Working Principle

The radial application of ultrasound is mainly based on the radial vibration characteristics generated when ultrasound propagates in a medium. When the ultrasonic waves generated by the ultrasonic transducer act on an object in a specific way, it will cause periodic elastic deformation in the radial direction. This radial vibration can trigger a series of physical effects, such as mechanical stirring, microfluidic effects, etc., thereby achieving various functions.

Product Introduction

Ultrasonic radial application products are based on the principle of ultrasonic radial vibration, which can induce physical effects in the medium. Like ultrasonic motors, which rely on radial vibration to drive the rotor, they have the advantages of fast response, high accuracy, and no electromagnetic interference, and are used in precision instruments; Ultrasonic cleaning equipment, using radial vibration to clean the interior of complex workpieces; Ultrasonic emulsification equipment utilizes strong radial vibration shear force to achieve efficient emulsification, and is applied in industries such as cosmetics and food. These products are efficient, highly targeted, and widely applicable, contributing to the development of multiple fields.

application area

Ultrasonic motor: uses the radial vibration of ultrasonic waves to drive the rotation of the motor rotor. The high-frequency radial vibration generated by the ultrasonic transducer is transmitted to the rotor through a special friction transmission structure, causing the rotor to continue rotating under the action of friction. Compared with traditional motors, ultrasonic motors have the advantages of fast response speed, high positioning accuracy, and no electromagnetic interference, and are commonly used in precision instruments, aerospace and other fields.

Ultrasonic cleaning: In some special cleaning needs, the radial vibration of ultrasonic waves can be used to more effectively clean complex shaped workpieces. For example, for components with deep holes, blind holes, or complex internal structures, the ultrasonic transducer is arranged in a suitable position so that the radial vibration it generates can act on every corner inside the workpiece, thereby more comprehensively removing surface dirt, grease, and particle impurities.

Ultrasonic non-destructive testing: When testing tubular structures such as pipelines and pressure vessels, the radial propagation of ultrasonic waves can be used to detect changes in the thickness of the pipe wall, internal defects, etc. By emitting radial ultrasonic waves and receiving reflected signals, the presence of defects such as cracks, holes, corrosion, etc. on the pipe wall can be determined based on the characteristics of the signals, as well as the location and size of the defects.

Phacoemulsification: during the emulsification process, the radial vibration generated by the ultrasonic transducer is applied to the mixed liquid to be emulsified. Through the strong shear force and micro flow effect generated by the radial vibration, the two immiscible liquids (such as oil and water) are fully mixed to form a uniform lotion. This method is used to prepare high-quality lotion products in cosmetics, food, pharmaceutical and other industries.

Detail Display

Mold customization

Operating Frequency |

15KHz/20KHz/28KHz |

Output Power |

1500~3000W |

Input Voltage |

AC220v 50Hz |

Amplitude Adjustment |

1%~100% |

Weld Time |

0.01~9.99s |

Connect To Air Pressure |

0.1~0.7MPa |

Machine maintenance and upkeep

Transducer maintenance: Regularly inspect the appearance of the transducer to see if there are cracks or damages, ensure that the connection parts are stable, and avoid loosening that affects energy conversion. If dirt is found on the surface of the transducer, gently wipe it with a soft and dry cloth to keep it clean.

Radial vibration components: Check the transmission components of radial vibration, such as bearings, shaft sleeves, etc., regularly add lubricating oil to reduce friction and wear. At the same time, check whether the vibrating components are deformed or damaged, replace the problematic parts in a timely manner, and ensure the stability of radial vibration.

Generator maintenance: Ensure that the working environment of the generator is dry and well ventilated, regularly clean the internal dust, and prevent excessive dust accumulation from affecting heat dissipation and performance. Check the parameter settings of the generator to ensure stable output frequency and power, and adjust them promptly if any abnormalities occur.

Electrical circuit: Check whether the electrical circuit is damaged or aged to avoid safety hazards such as short circuit and leakage. Tighten the connection points of the line to ensure stable signal transmission.

Performance testing: Regularly use professional testing equipment to test the output intensity, frequency accuracy, and other performance indicators of the ultrasonic radial system, promptly identify and solve potential problems, and ensure the normal operation of the system.