Ultrasonic Spot Welder OEM Supplier and Exporter for Quality Solutions

As a trusted OEM supplier, I’m excited to share my latest offering: the Ultrasonic Spot Welder. This advanced technology provides precision welding for a variety of materials, making it an essential tool for manufacturers. With our expertise at Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., you can count on a reliable solution that enhances production efficiency while maintaining high quality, My Ultrasonic Spot Welder is designed with durability and ease of use in mind, suitable for factories looking to improve their processes. It saves time and reduces labor costs, making it ideal for bulk production. As a reputable supplier, I ensure that each unit meets strict quality standards and is backed by excellent customer support, If you're in need of a top-notch welding solution, contact me today to learn how my Ultrasonic Spot Welder can meet your factory's specific requirements. Let's elevate your production capabilities together!

Step-by-Step Guide Ultrasonic Spot Welder Pioneers in the Field Service Backed by Expertise

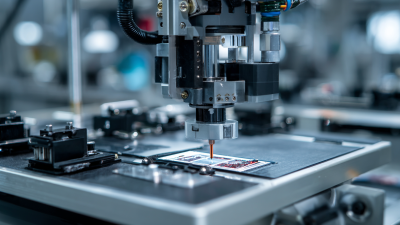

Ultrasonic spot welding has revolutionized the manufacturing process across various industries, offering unparalleled precision and efficiency in joining plastic components. This step-by-step guide will provide insights into how industry pioneers are leveraging cutting-edge ultrasonic technology to enhance their field service capabilities. With 20 years of expertise in ultrasonic plastic welding, professionals have honed their skills to deliver equipment that not only meets but exceeds the expectations of global buyers. At the heart of this advancement lies the ultrasonic plastic welding system, which employs high-frequency vibrations to generate localized heat at the interface between two materials. This process ensures a strong, durable bond while minimizing material distortion and damage. Key components of these systems include ultraSonic Welding equipment, lace technology, cutting equipment, extractors, and homogenizers, each designed to address specific applications and improve production efficiency. Investing in ultrasonic technology presents numerous benefits for manufacturers seeking to optimize operations. By choosing high-quality ultrasonic equipment, companies can reduce cycle times, lower operational costs, and enhance product quality. Furthermore, the ability to adapt ultrasonic solutions for various applications makes them an ideal choice for businesses aiming to remain competitive in an increasingly demanding global market. Explore how these innovations can transform your manufacturing processes and elevate your business to new heights.

Step-by-Step Guide Ultrasonic Spot Welder Pioneers in the Field Service Backed by Expertise

| Step | Description | Equipment Needed | Estimated Time | Expert Tips |

|---|---|---|---|---|

| 1 | Prepare surfaces to ensure proper bonding. | Cleaning Solution, Cloth | 10 minutes | Always use a lint-free cloth for optimal cleanliness. |

| 2 | Set up ultrasonic welder and test parameters. | Ultrasonic Welder, Parameter Guidelines | 15 minutes | Ensure to calibrate the machine for material type. |

| 3 | Align components for welding process. | Alignment Tools | 5 minutes | Double-check alignments to avoid miswelding. |

| 4 | Perform ultrasonic welding. | Ultrasonic Welder | 2 minutes | Monitor the process for consistent results. |

| 5 | Inspect and test the weld quality. | Testing Equipment, Inspection Tools | 10 minutes | Perform shear tests to verify bonding strength. |

Where the Value Lies Ultrasonic Spot Welder Market Leader Winning in 2025

S

Samuel Green

Definitely worth it! The expertise and professionalism of the support staff impressed me.

17 June 2025

S

Sophie Gonzalez

I can’t express how pleased I am! The quality and after-sales support were both exemplary.

21 May 2025

E

Evelyn Martin

Amazing quality product! The after-sales service has been just as exceptional, demonstrating their expertise.

05 July 2025

E

Emily Reed

Wonderful item! The customer service was exceptional and made me feel valued.

30 May 2025

S

Sebastian Johnson

Great investment! The product quality and professional after-sales support make it a win.

21 May 2025

C

Carter Ward

Outstanding experience! The quality stands out, and the staff was highly professional and helpful.

24 May 2025