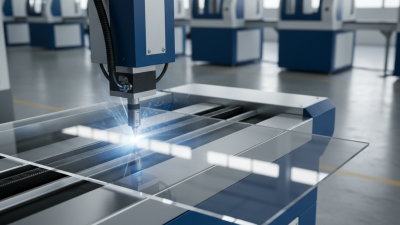

Ultrasonic Welding Horn OEM Solutions from Reliable Factory Suppliers

As a buyer in search of high-quality Ultrasonic Welding horns, I understand the importance of finding reliable suppliers and manufacturers. At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we offer a comprehensive range of ultrasonic welding horns specifically designed for various industrial applications. Our products are engineered for optimal performance, ensuring precise and efficient welding processes, Choosing us means you’re selecting a trusted supplier committed to excellence in ultrasonic equipment. Experience the benefits of our advanced technology and superior craftsmanship, and let's elevate your manufacturing process together

Key Steps to Choosing Ultrasonic Welding Horn Exceeds Industry Benchmarks Is The Best

When it comes to selecting the right ultrasonic welding horn, understanding the key steps can vastly improve operational efficiency and product quality. Ultrasonic welding is a highly effective technique for joining plastic components, and the horn plays a critical role in this process. To choose the optimal horn, first consider the material properties and geometry of the parts being joined. Different materials require specific horn designs to ensure optimal energy transfer and minimal degradation. Next, evaluate the frequency and amplitude requirements for your application. The right combination will enhance the welding process, resulting in durable joints that meet or exceed industry benchmarks. It's also important to assess the compatibility of the horn with your existing ultrasonic Welding Equipment. A well-matched system not only promotes efficiency but also extends the lifespan of both the horn and the welding machine. Finally, prioritize sourcing from reputable manufacturers that provide detailed specifications and support. A quality ultrasonic horn can dramatically impact production quality, and choosing a supplier committed to excellence will ensure you remain competitive in your field. By following these steps, procurement professionals can make informed decisions that lead to superior welding outcomes and increased operational efficiency.

Key Steps to Choosing Ultrasonic Welding Horn Exceeds Industry Benchmarks Is The Best

| Criteria | Description | Benchmark Status |

|---|---|---|

| Material Selection | Choosing high-quality materials that ensure durability and performance. | Exceeds |

| Design Specifications | Custom designs optimizing ultrasonic vibrations for specific applications. | Meets |

| Frequency Matching | Ensuring the horn frequency matches the ultrasonic generator’s output. | Exceeds |

| Amplitude Control | Adjustable amplitude settings for different welding applications. | Exceeds |

| Thermal Stability | Resistance to high temperatures improving lifespan and functionality. | Meets |

Methods To choose Ultrasonic Welding Horn Guarantees Peak Performance Service

S

Sophia Robinson

Absolutely love this product! The service I received from the team was professional and attentive, making me a loyal customer.

17 May 2025

G

Gabriel Foster

Simply put, great quality! The after-sales service was attentive and professional.

14 June 2025

E

Ella Ward

Remarkably great product! After-sales service was a joy to experience due to their professionalism.

28 June 2025

J

Jacob Harris

Top-notch product! The support staff were not only helpful but also very knowledgeable.

14 June 2025

L

Landon Bell

A fantastic experience! The quality is evident, and the support team exemplifies professionalism.

02 July 2025

M

Madelyn Baker

One of my best purchases! The quality is impressive, and the service team is incredibly professional.

16 June 2025