- Ultrasonic horn

- Ultrasonic plastic welding machine

- Ultrasonic metal welding machine

- Ultrasonic sewing machine

- Ultrasonic cutting device

- Ultrasonic homogenizer

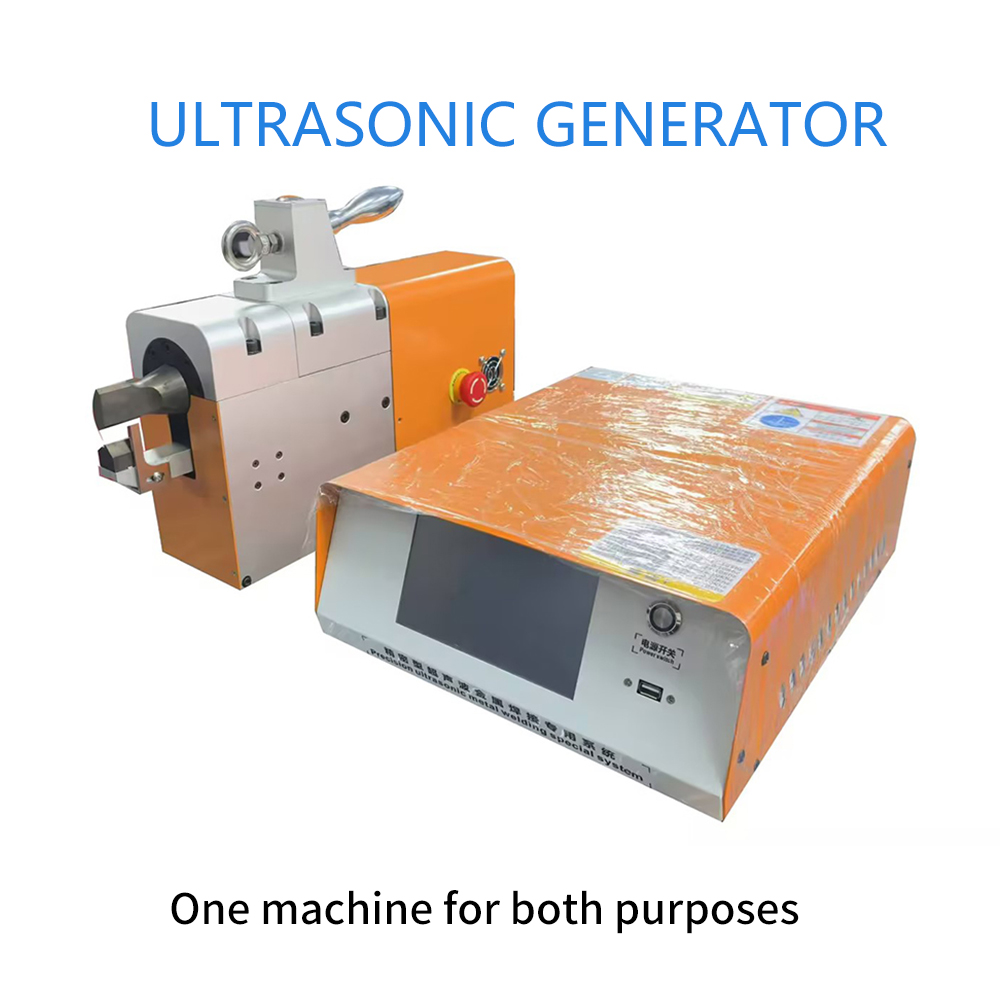

- The ultrasonic generator

- Ultrasonic transducer

- Ultrasonic spot welding, handheld welding

- Ultrasonic hose sealing machine

- Ultrasonic turntable machine

- Water outlet machine

- Flange

01

Ultrasonic welding machine for copper wire welding and cutting

short description part

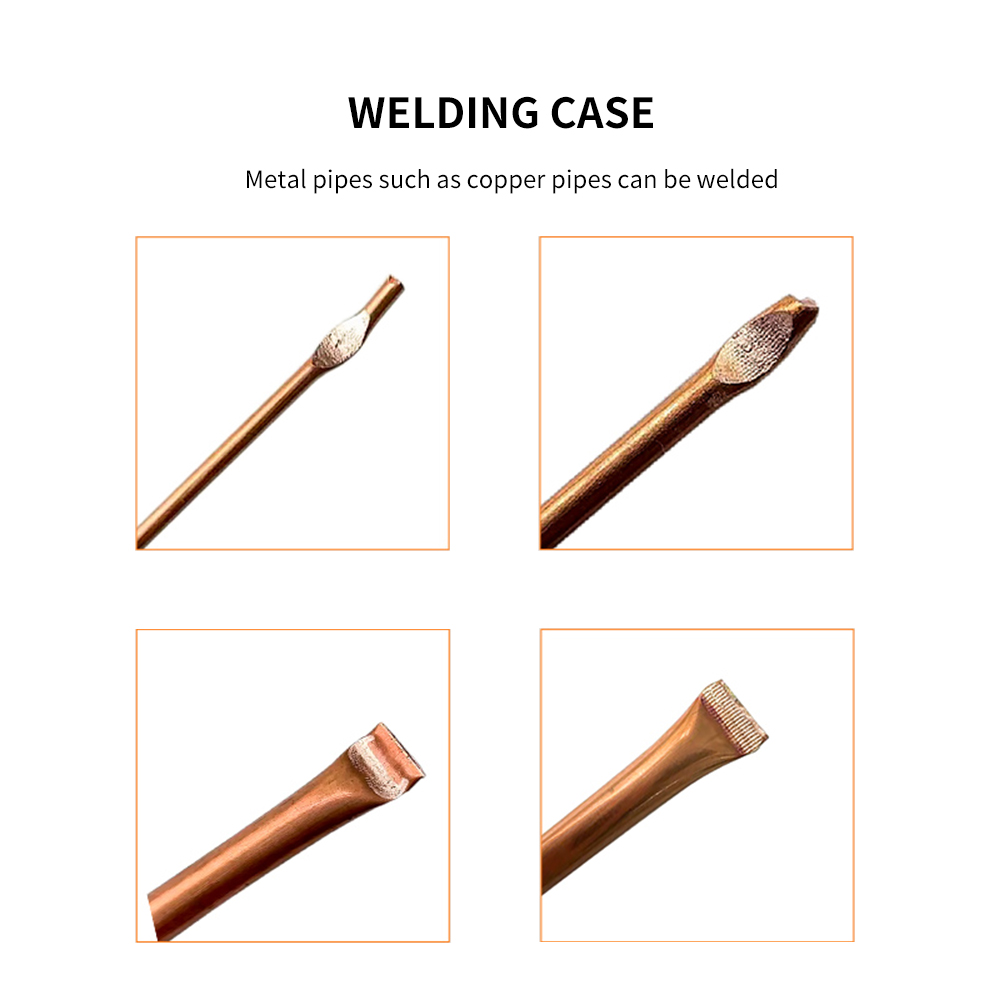

Wide range of applications : Suitable for sealing various copper tubes, aluminum tubes and other metal tubes below φ12mm. Some equipment, such as Das Technology's ultrasonic copper tube tail sealing machine, can achieve the sealing and cutting of copper and aluminum tubes with a diameter of less than 15mm and a wall thickness of less than 1.3mm3.

Easy operation : convenient manual operation, high degree of equipment automation, good welding consistency, some equipment also has automatic alarm function for defective welding products, and manual frequency adjustment is eliminated38.

Safety and health : There is no open flame, smoke or odor during cutting and welding, and no adverse effects on operators8.

working principles

The high-frequency ultrasonic vibration waves are transmitted to the surface of the metal tube. Under pressure, the metal surfaces are rubbed against each other to form a fusion between the molecular layers, thereby achieving sealing. In this process, the energy of ultrasonic vibration is converted into friction energy and transmitted to the metal surface. While friction generates heat, pressure is applied to fully activate and fuse the metal structure molecules.

Product Introduction

The ultrasonic copper tube sealing machine uses ultrasonic high-frequency vibration wave technology to make the surfaces of the copper tube rub against each other under pressure, promoting the fusion of molecular layers to achieve sealing.

It is efficient and fast, can complete the operation in a short time, and improve production efficiency; the sealing quality is reliable, the strength is high, and it is not easy to leak air or liquid; it is environmentally friendly and energy-saving, does not require additional welding materials, and has low energy consumption. The equipment has a wide range of applications and can seal copper tubes below φ12mm.

This equipment is mainly used in the refrigeration industry, such as sealing copper tubes in refrigerators and air conditioners; it is also used in the fields of automobile manufacturing, aerospace, electronic equipment, etc. When operating, it is necessary to check the equipment in advance, prepare the pipes, and set the parameters reasonably. Cleaning, component inspection, and lubrication maintenance should be done daily to ensure stable operation of the equipment.

application areas

Refrigeration industry : widely used in refrigerators, air conditioners, freezers and other refrigeration equipment, used for sealing copper tubes, aluminum tubes and other refrigeration pipelines to ensure the sealing and performance stability of the refrigeration system, such as welding of inflatable tube products in thin tubular and spherical temperature sensors in air conditioners, refrigerators and refrigeration controllers 245.

Automobile manufacturing : It can be used for sealing copper and aluminum tubes in automobile air-conditioning systems, as well as connecting and sealing some metal tubes in automobile electronic equipment.

Aerospace : In the manufacture of some precision equipment in the aerospace field, the sealing of metal pipes requires high sealing quality and strong reliability. Ultrasonic copper tube sealing machines can meet these requirements.

Electronic equipment : Ultrasonic copper tube sealing machines are also used to seal the heat dissipation copper tubes or other metal tubes in electronic equipment such as computers and mobile phones.

details display

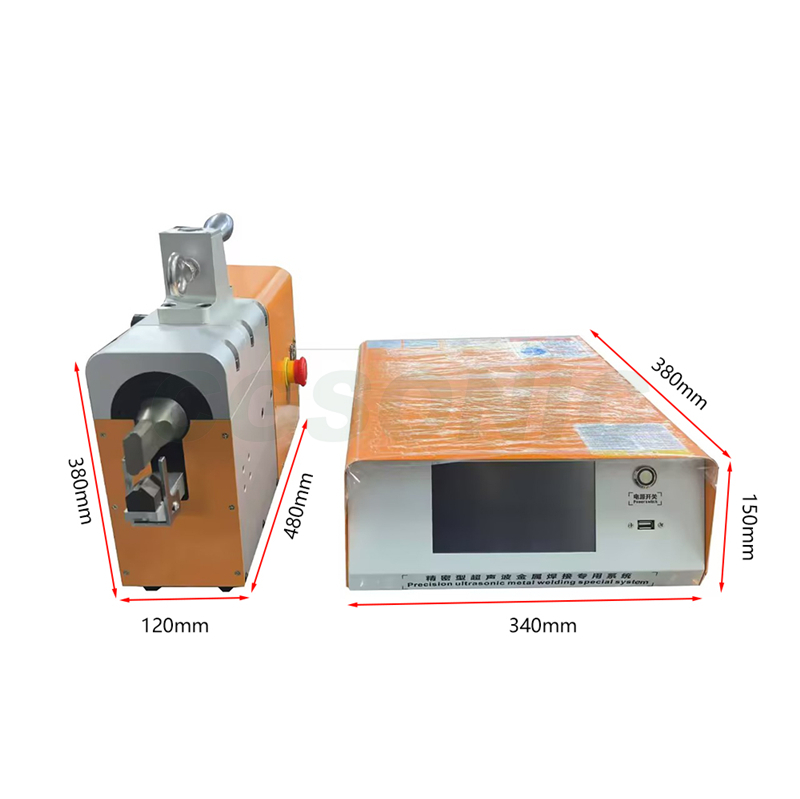

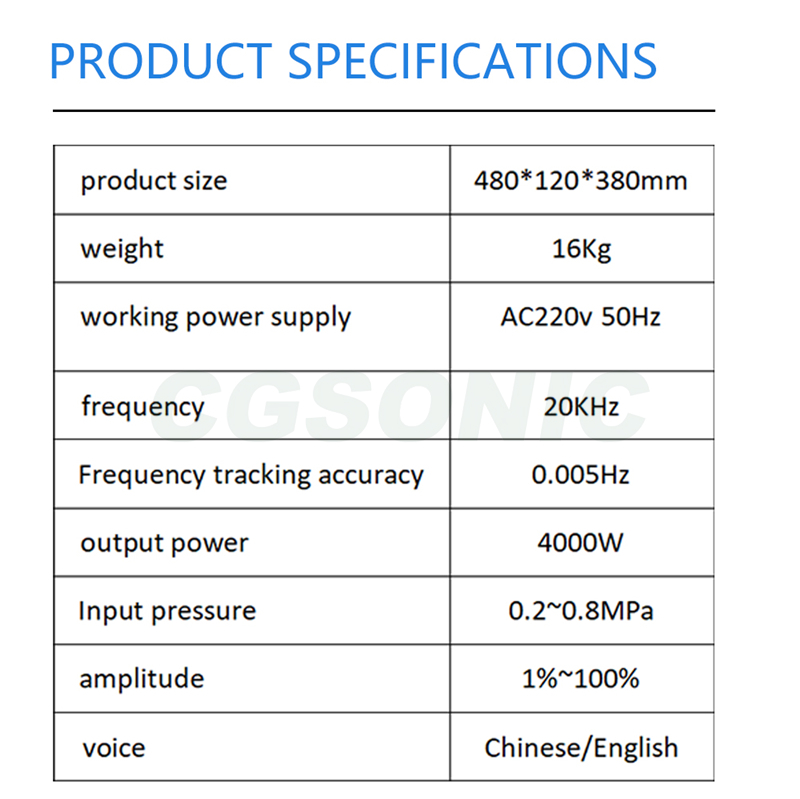

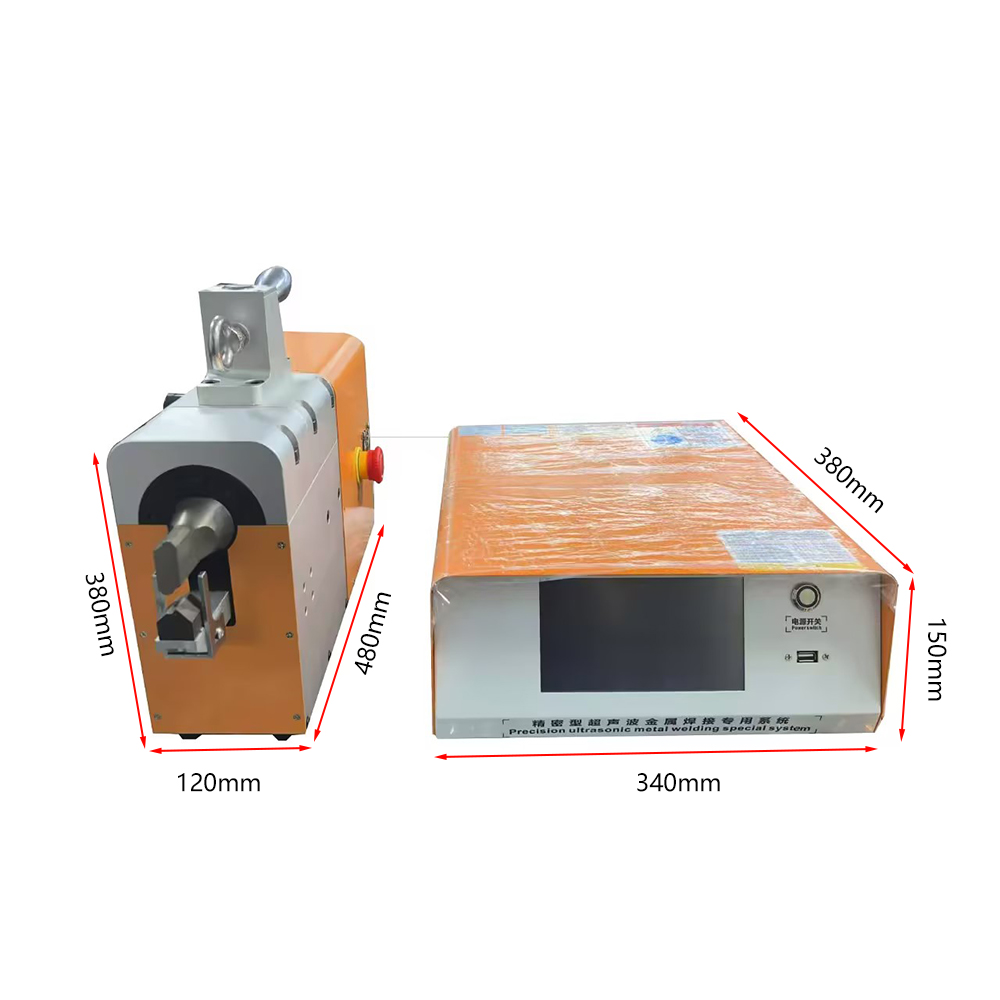

Product Parameters

Product size |

480*120*380mm |

Output Power |

4000W |

weight |

16Kg |

Input air pressure |

0.2~0.8MPa |

Working power supply |

AC220v 50Hz |

amplitude |

1%~100% |

frequency |

20KHz |

voice |

Chinese/English |

Tracking accuracy |

0.005Hz |

|

Machine maintenance

Mechanical parts : Regularly add lubricating oil to the transmission parts (such as screws, slide rails, and sliders) to ensure smooth movement and reduce wear. Check whether the clamping force of the fixture is normal to ensure that the copper tube is firmly fixed during the sealing process. If the fixture is worn, replace it in time. Check the bolts of each mechanical connection part and tighten them in time if they are loose.

Electrical system : Check the circuit for damage and aging to prevent short circuit and leakage. Clean the dust in the electrical box regularly to ensure good heat dissipation of electrical components. Test whether the control buttons, display screen, etc. are working properly. If there is any fault, repair or replace it in time.

Ultrasonic system : Keep the working environment of the ultrasonic generator dry and avoid moisture. Check the parameter settings of the generator regularly to ensure stable output power and frequency. Check whether the connection between the transducer and the horn is firm and whether there are any abnormal conditions such as cracks and wear. If there are any problems, deal with them in time.

Sealing mold : After each use, clean the metal residue on the sealing mold to prevent affecting the sealing effect next time. Check the wear of the mold regularly. If the wear is serious, replace it in time to ensure the quality and sealing of the sealing.

Regular inspection : Regularly perform performance inspections on the entire machine, such as tail sealing strength, tail sealing time, ultrasonic output intensity, etc., to promptly identify and resolve potential problems and ensure that the equipment is in the best working condition.

After-Sales Service

We provide a one-year warranty service for our products and will fully protect your usage rights during the warranty period. In addition, if you encounter any questions or technical issues during use, our professional online technical support team will be available to answer your questions and provide you with efficient and thoughtful solutions.