Ultrasonic Welding Plastic: OEM Factory Suppliers for Quality Solutions

At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., I’m excited to share our top-of-the-line Ultrasonic Welding plastic solutions designed for diverse industries. As a leading manufacturer and ODM supplier, we focus on delivering high-quality equipment that meets the specific needs of B2B purchasers. Our advanced ultrasonic technology ensures precise and reliable bonding of plastic components, making your production processes more efficient, With years of experience in the field, we understand the demands of the market and are dedicated to serving our clients with customized solutions. Our products not only enhance productivity but also align with sustainability goals. I invite you to explore our offerings and see how our ultrasonic welding plastic equipment can elevate your manufacturing capabilities. Let’s work together to create innovative solutions that drive your business forward!

Why Ultrasonic Welding Plastic Products From Concept to Delivery

Ultrasonic welding has revolutionized the manufacturing landscape, particularly in producing durable and efficient plastic products. At Chengguan, with two decades of expertise in ultrasonic Plastic Welding, we understand the intricacies involved in bringing concepts to life. Our extensive product offerings, including ultrasonic plastic welding systems and equipment, are tailored to meet the diverse needs of industries worldwide. This precision technology enables seamless joining of materials without the need for additional adhesives, ensuring both strength and reliability. From the initial design phase to final delivery, we prioritize collaboration with our clients. Our team works closely with businesses to refine product specifications, enhancing performance through advanced ultrasonic lace and cutting equipment. Additionally, our ultrasonic extractors and homogenizers ensure quality control throughout the production process. This integrated approach not only simplifies the sourcing of components but also guarantees that the finished products meet the highest standards. Companies seeking innovative, efficient, and sustainable solutions will find that Chengguan is a trusted partner in navigating the journey from concept to market-ready products.

Why Ultrasonic Welding Plastic Products From Concept to Delivery

| Phase | Description | Duration (Weeks) | Key Activities |

|---|---|---|---|

| 1. Concept Development | Identify product requirements and concepts. | 2 | Market research, brainstorming sessions, feasibility studies. |

| 2. Design and Prototyping | Create designs and prototypes using CAD tools. | 4 | 3D modeling, prototyping, initial testing. |

| 3. Material Selection | Choose suitable materials for ultrasonic welding. | 1 | Material research, supplier evaluation. |

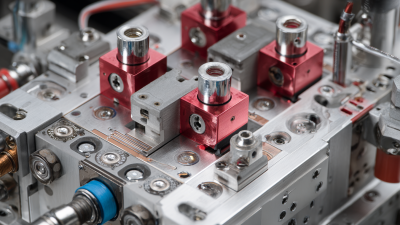

| 4. Tooling & Fixture Design | Design tooling and fixtures for production. | 3 | Tool design, manufacturing prototypes, testing tools. |

| 5. Production Run | Execute the first full production run. | 6 | Set up equipment, run tests, schedule production. |

| 6. Quality Assurance | Conduct quality checks and tests on produced goods. | 2 | Inspection, testing, compliance checks. |

| 7. Delivery & Launch | Prepare for launch and deliver products to customers. | 2 | Packaging, shipping logistics, marketing launch. |

Simple Ways To Ultrasonic Welding Plastic From Concept to Delivery Factory

J

Jessica Thompson

I was thoroughly impressed by the professionalism of the support staff. They resolved my issue promptly and courteously.

03 July 2025

C

Chase Foster

This product truly stands out! And the professionalism of the support staff made the experience better.

20 June 2025

I

Isabella Murphy

Unmatched quality! The professionalism and efficiency of the service staff were commendable.

23 June 2025

S

Sofia James

Just love this product! The after-sales support was not only quick but very professional.

12 May 2025

L

Luke Phillips

The quality truly stands out! The support team was not only professional but also very friendly.

21 June 2025

O

Olivia Adams

Absolutely wonderful! The quality of the product and the after-sales service worked perfectly together.

25 June 2025