Wholesale Plastic Welders: Leading Exporters & Factories Worldwide

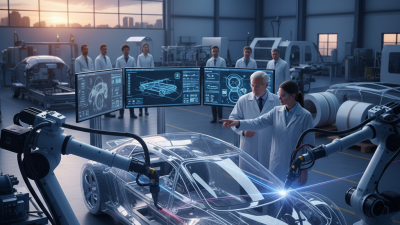

As a dedicated supplier of high-quality Welder Plastic solutions, I understand the unique needs of B2B purchasers like you. At Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd., we specialize in custom ultrasonic welding equipment that ensures precision and efficiency. Our factories utilize advanced technology and robust materials, allowing us to deliver tailored solutions for your specific requirements. Whether you're in automotive, electronics, or packaging industries, our welders provide the reliability you need to enhance your production processes. I strive to build strong partnerships with our clients, ensuring that you receive not just a product, but a comprehensive solution designed to improve your operations. Let's work together to find the perfect welder plastic equipment that meets your demands and exceeds your expectations. Reach out today to learn more about our offerings and how we can support your business growth!

Practical Methods To Welder Plastic Custom Solutions, Where Service Meets Innovation

In today's fast-paced industrial landscape, sourcing reliable and innovative solutions for Plastic Welding is crucial for manufacturers across various sectors. For over two decades, the ultrasonic plastic welding technology has revolutionized the way businesses approach production processes. The ability to seamlessly join plastic components through ultrasonic energy offers numerous advantages, including improved bond strength, reduced cycle times, and enhanced product quality. The practical application of ultrasonic technology not only caters to the diverse needs of various industries but also emphasizes customization—ensuring that each client receives solutions that are tailored to their specific requirements. Advancements in ultrasonic welding systems have enabled manufacturers to embrace innovation while maintaining the highest standards of service. With a comprehensive range of equipment including ultrasonic lace, cutting, and extraction systems, businesses can streamline their operations and enhance efficiency. These innovative solutions facilitate quick integration into existing workflows, allowing for a smooth transition and minimizing production downtime. By leveraging the latest technological advancements, companies can meet increasing market demands while ensuring their products stand out in terms of quality and durability. Furthermore, as global supply chains evolve, the need for reliable partners who understand the nuances of ultrasonic technology becomes vital. Engaging with experts who can provide not just equipment but also ongoing support fosters collaborative relationships that drive innovation. By focusing on practical methods that align service with cutting-edge solutions, manufacturers can effectively navigate the complexities of the market and position themselves for sustainable growth. In conclusion, the future of plastic welding lies in harnessing the power of ultrasonic technology to deliver bespoke solutions that not only meet client needs but also set new industry standards.

Practical Methods To Welder Plastic Custom Solutions, Where Service Meets Innovation

| Method | Description | Applications | Advantages |

|---|---|---|---|

| Ultrasonic Welding | Uses high-frequency ultrasonic vibrations to create a frictional heat that melts plastic. | Automotive parts, electronics, medical devices. | Fast processing, minimal energy usage, no need for additional adhesives. |

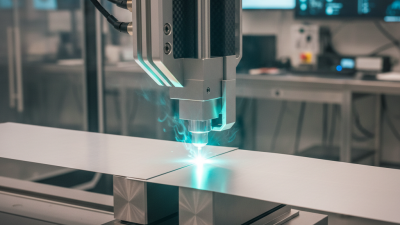

| Laser Welding | Employs laser beams to melt and join plastic parts with precision. | Thin-walled plastic, optical components, medical equipment. | High precision, clean process, and the ability to weld transparent materials. |

| Hot Plate Welding | Involves heating a common plate that softens the plastic parts to be joined. | Large parts, housing assemblies, and bulk items. | Effective for thick materials and allows for larger joining areas. |

| Spin Welding | Rotational motion is applied to one of the parts, generating heat from friction. | Caps, containers, and pipe fittings. | Simple setup and reliable welds for cylindrical parts. |

10 Essential Tips For Welder Plastic Guarantees Peak Performance Service Backed by Expertise

T

Thomas Young

High-quality product! The service team was not only knowledgeable but also incredibly patient.

18 June 2025

E

Ella Davis

The quality is amazing! The after-sales team was responsive and genuinely cares for their customers.

01 June 2025

A

Andrew Cook

Great product! I greatly appreciated the expert advice provided by the support team.

08 June 2025

J

Joshua Hill

This purchase was a wise decision! The support team showcased professionalism throughout.

17 June 2025

G

Gabriel Foster

Simply put, great quality! The after-sales service was attentive and professional.

14 June 2025

M

Mia Lee

Incredible product! Their after-sales team provided excellent and timely assistance, which I truly appreciate.

18 June 2025