Welding Machine Card: ODM Solutions by Leading Exporters & Factories

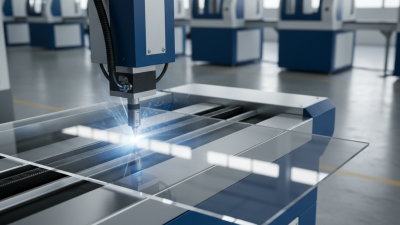

As a business owner in the manufacturing sector, I understand the importance of reliable equipment for maximizing productivity. That's why our Welding Machine Card stands out for wholesale buyers and factories seeking quality and efficiency. Designed for seamless integration, this card enhances the performance of welding machines, ensuring precision and consistency in every weld, With Shenzhen Chengguan Intelligent Ultrasonic Equipment Co., Ltd. as a trusted supplier, you can count on us for durable and innovative solutions tailored to meet your operational needs. Our commitment to excellence means you get top-notch technology without compromises, Partnering with us not only provides you access to advanced welding machine components but also dependable support and service. Whether you're a factory director or a procurement officer, I believe our Welding Machine Card will be a valuable asset to your production line. Let’s elevate your manufacturing capabilities together!

10 Essential Tips For Welding Machine Card Exceeds Industry Benchmarks More Than a Supplier - A Partner

When it comes to finding a reliable supplier for ultrasonic plastic welding equipment, it’s crucial to look beyond just the products offered. The most successful partnerships flourish when suppliers position themselves as valued partners rather than mere vendors. This approach fosters collaboration, understanding, and innovation tailored to your specific needs. Here are ten essential tips to ensure that your welding machine supplier transcends the typical supplier role and becomes a true partner in your projects. First, evaluate the supplier's industry expertise and experience. A partner with extensive knowledge in ultraSonic Welding can offer insights that optimize your production processes and improve end-product quality. Additionally, consider their customer support and technical assistance. A partner should provide ongoing support, including training and troubleshooting, to ensure your team can fully leverage the capabilities of the equipment. Transparency in communication regarding lead times, pricing, and product specifications is also vital, as it builds trust and facilitates smoother transactions. Finally, assess their commitment to innovation and adaptation. In a fast-evolving industry, a proactive partner invests in research and development to remain at the forefront of technology. Collaborate with your supplier to align on future projects and ensure that they can scale their offerings in line with your business growth. By selecting a partner that meets these criteria, you can ensure that your ultrasonic welding needs are met with precision and that your operations exceed industry benchmarks.

| Tip Number | Tip Description | Benefit | Implementation |

|---|---|---|---|

| 1 | Understand the type of welding needed | Ensures effective welding process | Assess project requirements and materials |

| 2 | Choose the right welding machine | Optimizes performance and results | Research specifications and ratings |

| 3 | Maintain equipment regularly | Prolongs lifespan and increases safety | Set a routine maintenance schedule |

| 4 | Use appropriate filler materials | Ensures strong and durable welds | Consult specifications for compatibility |

| 5 | Train operators properly | Enhances skill and efficiency | Implement ongoing training sessions |

| 6 | Ensure proper safety equipment | Reduces risk of injury | Assess and provide required PPE |

| 7 | Monitor voltage and settings | Prevents equipment damage | Check and calibrate regularly |

| 8 | Keep a clean workspace | Fosters safety and efficiency | Regularly organize and clean |

| 9 | Evaluate production outcomes | Improves future processes | Conduct post-project reviews |

| 10 | Seek feedback from team | Enhances teamwork and improvements | Implement regular feedback sessions |

Why Welding Machine Card Service Service Backed by Expertise

J

Jack Nelson

Such a great product! The service personnel were well-informed and quick to assist.

06 July 2025

G

Grace Hughes

I absolutely love this product! The professionalism and courtesy of the service team were impressive.

17 June 2025

G

Gabriel Foster

Simply put, great quality! The after-sales service was attentive and professional.

14 June 2025

L

Logan Perez

Pleased with the product! The after-sales support team was top-notch and very efficient.

01 July 2025

S

Scarlett Powell

Quality that exceeds expectations! The after-sales team was incredibly professional and skilled.

07 July 2025

L

Luke Phillips

The quality truly stands out! The support team was not only professional but also very friendly.

21 June 2025